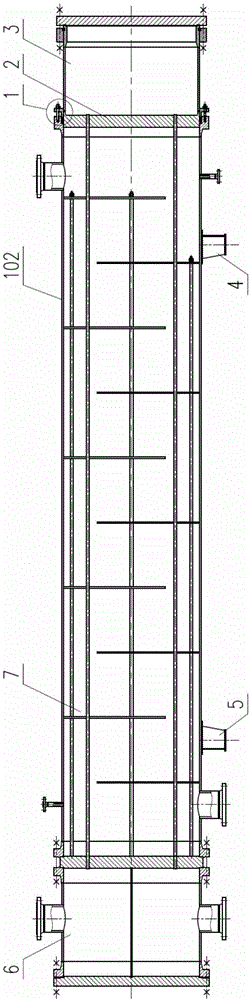

Stuffing box sealing structure, horizontal type stuffing box heat exchanger with same and installation method

A sealing structure and heat exchanger technology, which is applied in the sealing of engines, engine components, mechanical equipment, etc., can solve the problem of large gap between the tube sheet and the upper wall of the shell shell, the inability of the packing to expand normally, and the difficulty in installing the packing packing, etc. problem, to achieve the effect of eliminating uneven width, uniform width and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

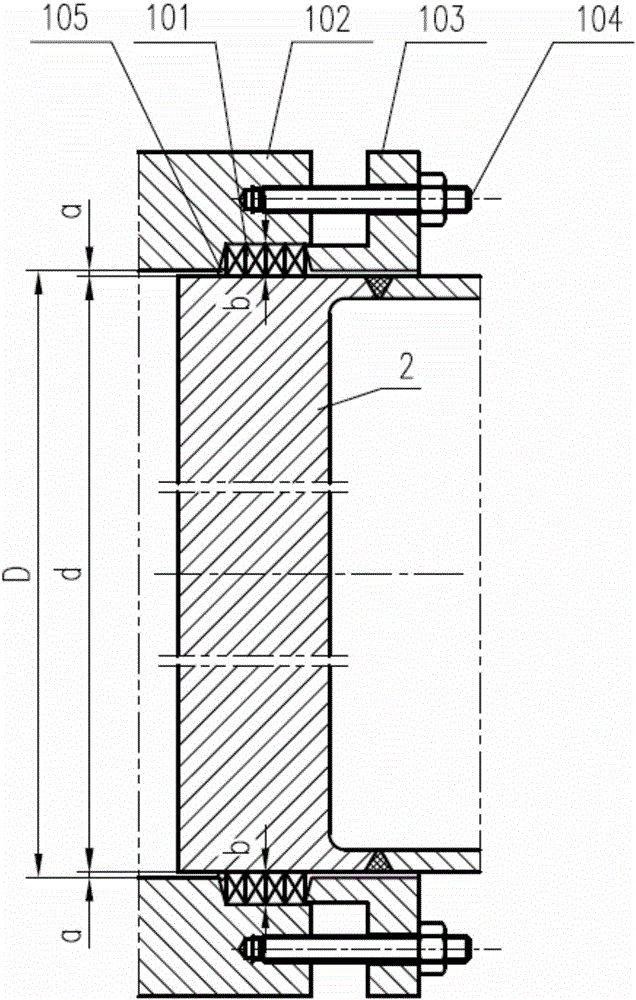

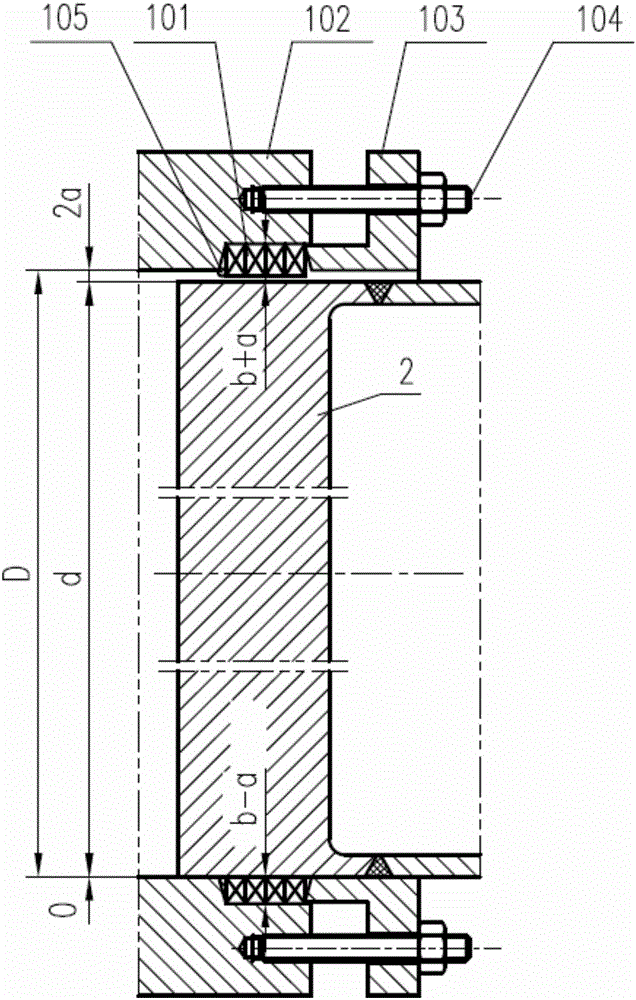

[0040] A stuffing box sealing structure for a horizontal heat exchanger, comprising: a retaining ring 106 arranged at the front end of the packing chamber between the tube sheet 2 and the shell side shell 102 and divided into two petals equally, and a retaining ring arranged in the packing chamber The packing 101 at the rear, and the packing gland 103 that seals the packing in the packing cavity. The packing gland 103 is fixed on the shell-side shell by studs 104, wherein the outer diameter of the retaining ring is the inner diameter of the shell-side shell -0.1mm, the inner diameter of the retaining ring is the outer diameter of the tube sheet +0.1mm, and the tube bundle is installed in the shell-side shell Finally, the gap c between the retaining ring and the tube sheet and the gap between the shell side and the shell are close to 0, and the actual width of the packing cavity is basically uniform up and down, so the sealing performance is excellent.

Embodiment 2

[0042] A stuffing box sealing structure for a horizontal heat exchanger, comprising: a retaining ring 106 arranged at the front end of the packing chamber between the tube sheet 2 and the shell side shell 102 and divided into two petals equally, and a retaining ring arranged in the packing chamber The packing 101 at the rear, and the packing gland 103 that seals the packing in the packing chamber. The packing gland 103 is fixed on the shell-side shell by studs 104, wherein the outer diameter of the baffle ring is equal to the inner diameter of the shell-side shell, and the inner diameter of the baffle ring is equal to the outer diameter of the tube sheet. After the tube bundle is installed in the shell-side shell, the baffle ring and the tube The gap c between the plate and the shell side is 0, the width of the packing cavity is completely uniform up and down, and the sealing performance is very good.

Embodiment 3

[0044] A stuffing box sealing structure for a horizontal heat exchanger, comprising: a retaining ring 106 arranged at the front end of the packing chamber between the tube sheet 2 and the shell side shell 102 and divided into two petals equally, and a retaining ring arranged in the packing chamber The packing 101 at the rear, and the packing gland 103 that seals the packing in the packing chamber. The packing gland 103 is fixed on the shell-side shell by studs 104, wherein the outer diameter of the retaining ring is the inner diameter of the shell-side shell -0.1mm, the inner diameter of the retaining ring is the outer diameter of the tube sheet +0.1mm, and the tube bundle is installed in the shell-side shell Finally, the gap c between the retaining ring and the tube sheet and the gap between the shell side and the shell are close to 0, and the actual width of the packing cavity is basically uniform up and down, so the sealing performance is excellent. At the same time, three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com