Workpiece discharging and dividing system

A technology for subpackaging systems and workpieces, applied in packaging, solid materials, transportation and packaging, etc., can solve the problems of manpower consumption and low work efficiency, and achieve the effects of improving work efficiency, improving operation safety and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

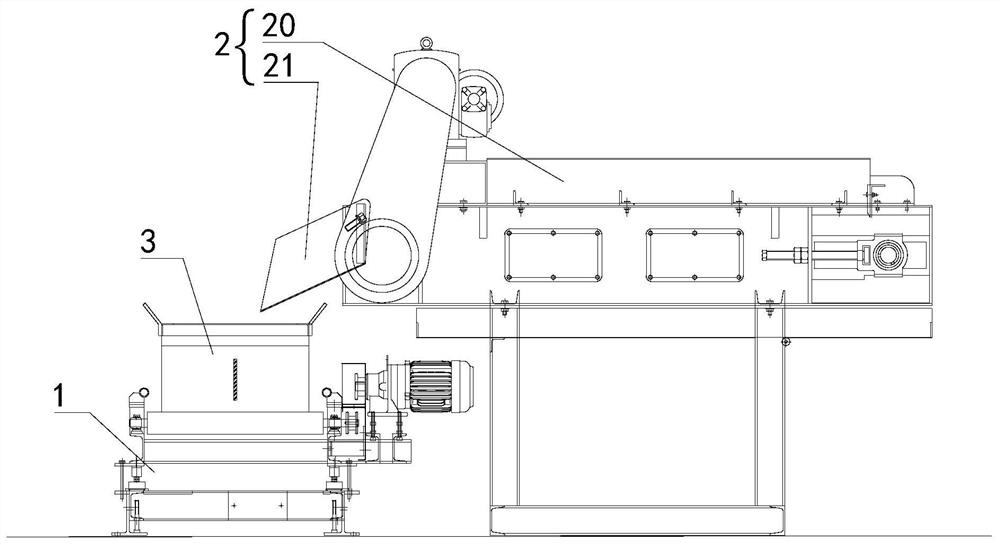

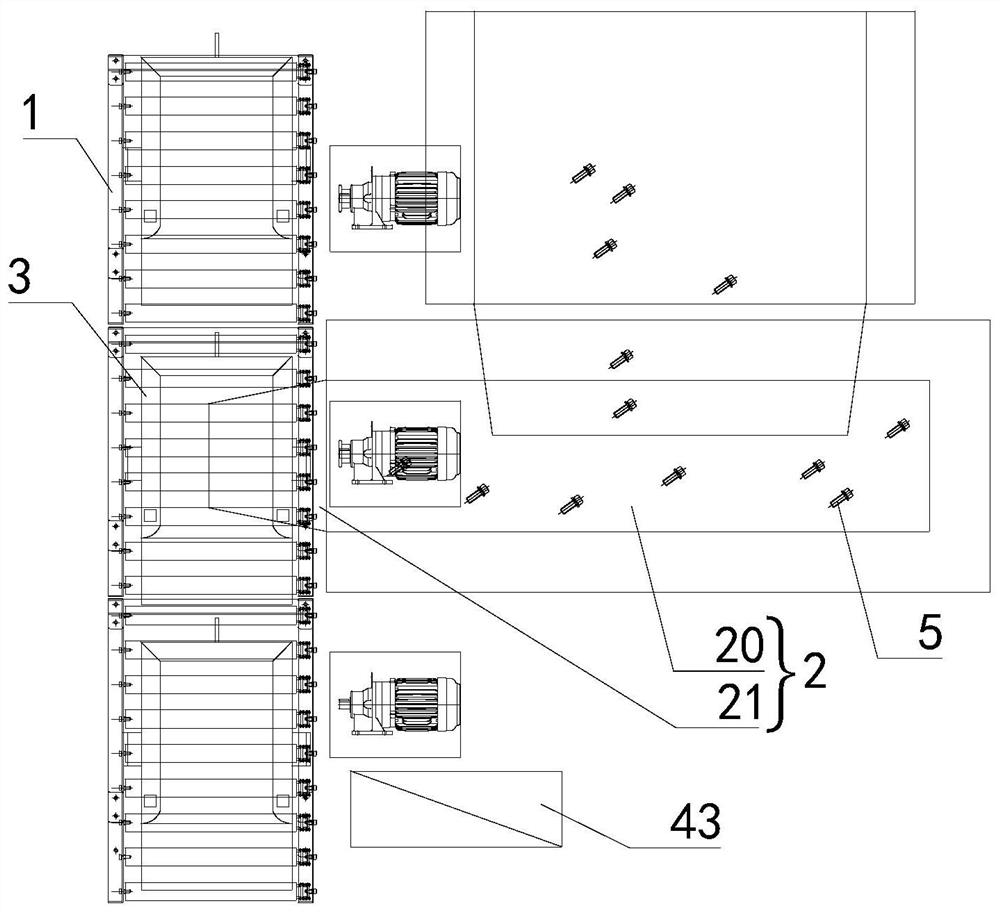

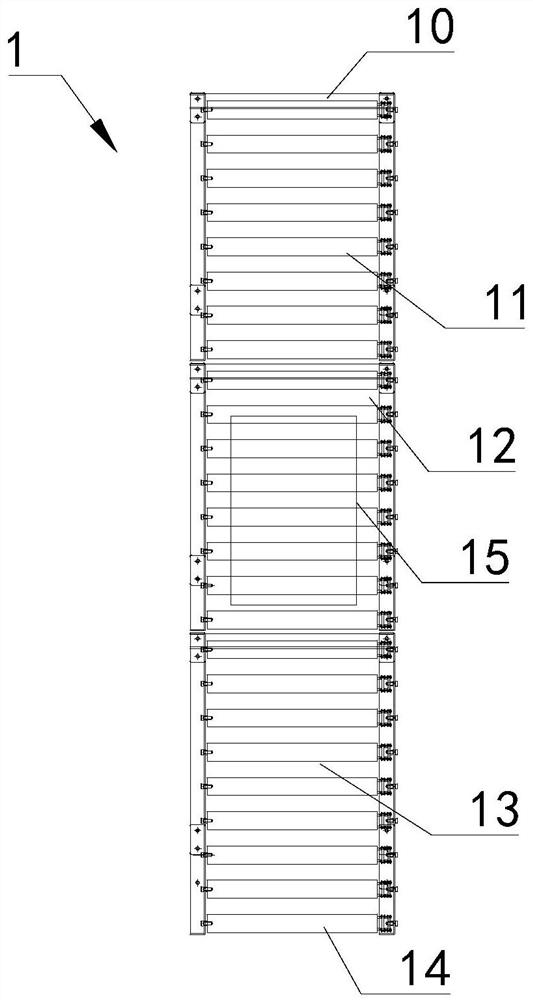

[0039] see Figure 1 to Figure 4 As shown, the present embodiment provides a workpiece discharging and packaging system; figure 1 The first structural schematic diagram of the workpiece discharging and packaging system provided in this embodiment, specifically, shows the front view of the workpiece discharging and packaging system; figure 2 for figure 1 top view of image 3 for figure 2 Schematic diagram of the transmission mechanism in ; Figure 4 The control principle block diagram of the workpiece discharging and packaging system provided in this embodiment.

[0040] see Figure 1 to Figure 4 As shown, the workpiece discharging and packaging system provided in this embodiment includes a transmission mechanism 1, a station device 3, a discharging mechanism 2, a weighing mechanism 44, a driving mechanism, a first position sensor 40, a frequency conversion mechanism 41, a second A position sensor 42 , a human-computer interaction device 43 and a controller 45 .

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com