Aeroengine counterweight screw assembling and disassembling tool and assembling and disassembling method thereof

An aero-engine and screw technology, applied in the direction of manufacturing tools, wrenches, wrenches, etc., can solve the problem of narrow space in the installation area of counterweight screws, shorten the maintenance cycle, avoid damage, and facilitate observation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below with reference to the accompanying drawings.

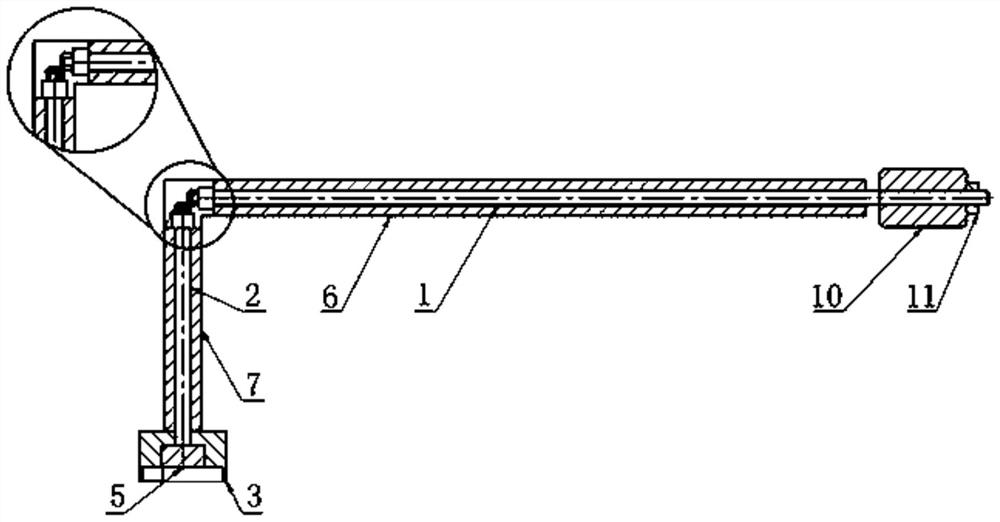

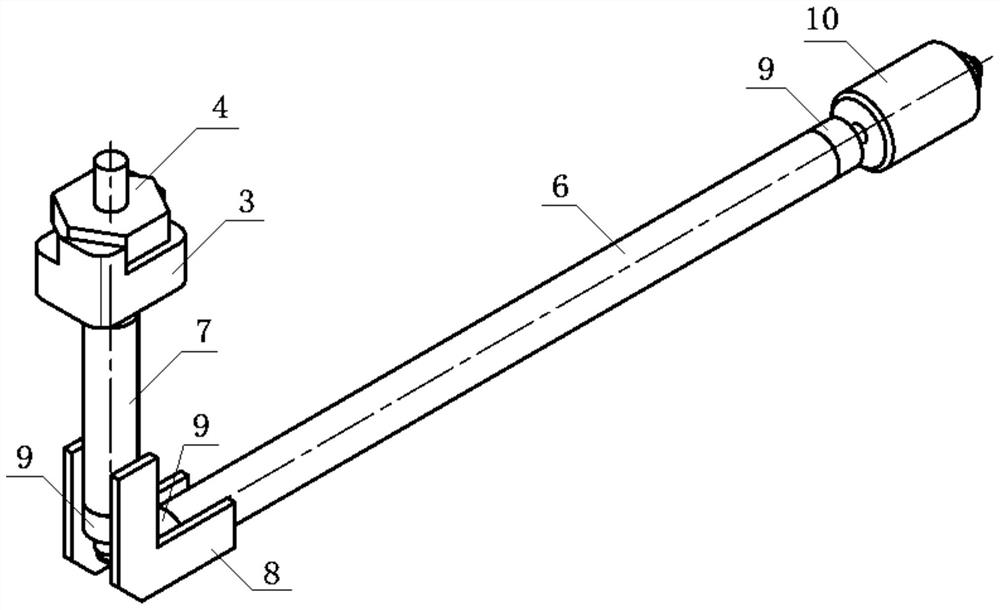

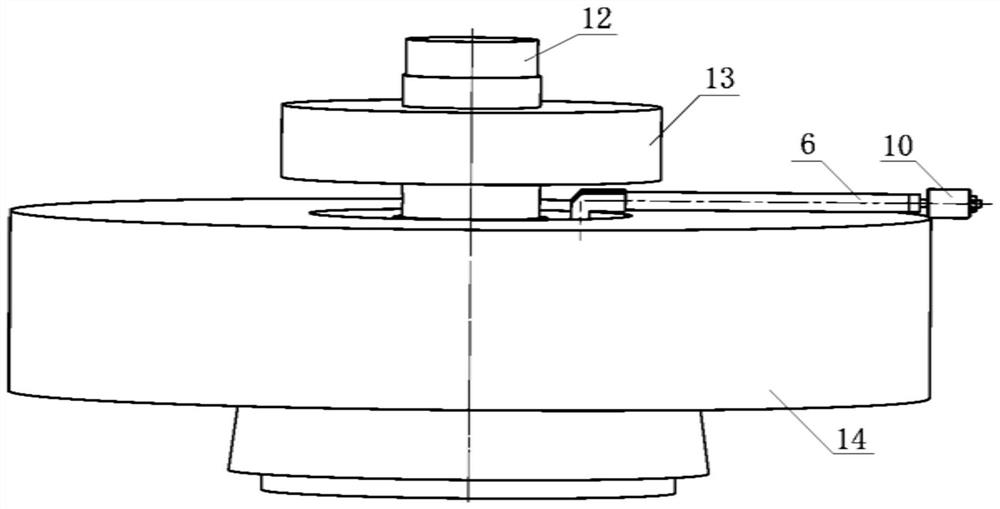

[0027] See figure 1 with figure 2 The aviation engine weight screw dispensing tool of the present invention includes a sleeve, a first drive rod 1, a second drive rod 2, and a wrench 3. The sleeve is monolithic in the hollow structure, and the sleeve can be a whole, see figure 1 ; Or see figure 2 The sleeve includes the first sleeve 6 and the second sleeve 7, the first sleeve 6 and the second sleeve 7 are perpendicular to each other and the two connection plates 8 are welded, and the two connecting plates 8 are L-shaped and relative. Arrange. The first driving rod 1 and the second drive rod 2 are provided inside the sleeve, and the first driving rod 1 and the second drive rod 2 are connected by the transmission structure at the corner of the sleeve, and the transmission structure refers to the rotation of the first drive rod 1, The second drive rod 2 can be rotated synchrono...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com