Sub-packaging device for electronic component production

A technology for electronic components and sub-packaging, which is applied in solid separation, chemical instruments and methods, and sieves, etc., can solve the problems of not improving work efficiency, increasing labor costs, and increasing labor volume of workers, so as to reduce labor volume. , The effect of improving the efficiency of sub-packaging and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

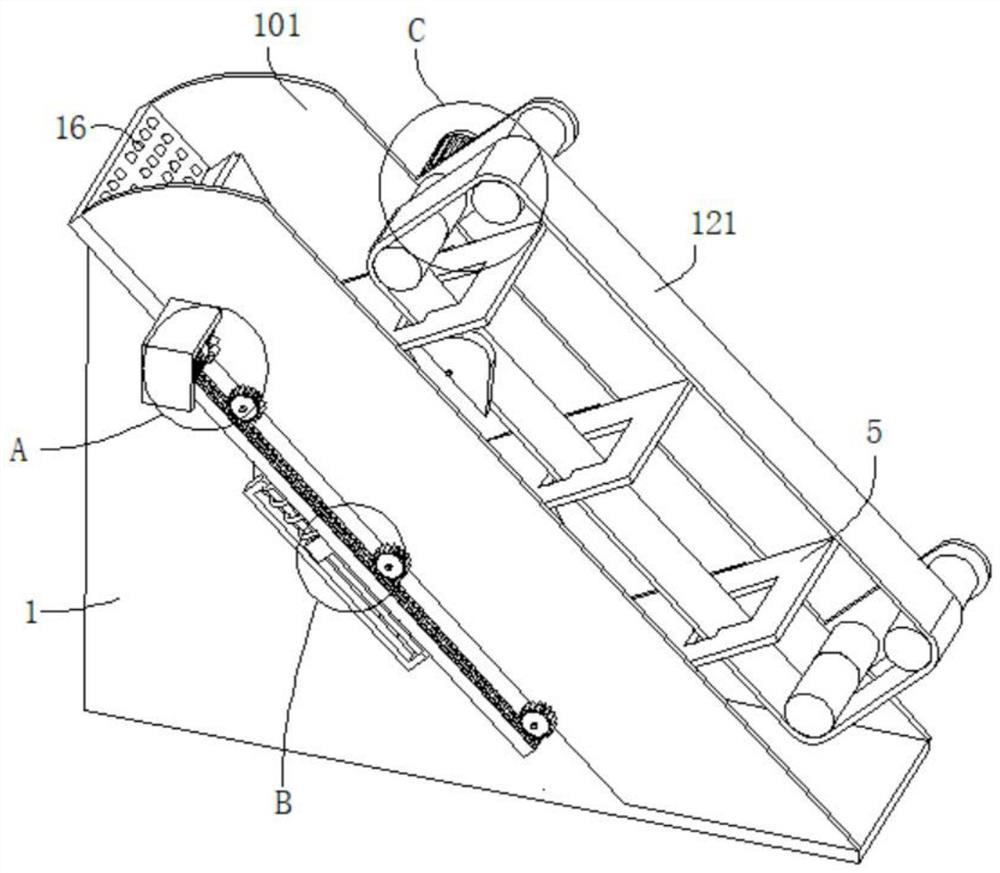

[0035] refer to Figure 1-5, a subpackaging device for the production of electronic components, comprising a triangular housing 1, side plates 101 are connected to both sides of the outer wall of the triangular housing 1, and first grooves 2 are respectively dug on the top outer wall of the triangular housing 1 and the second groove 3, the first groove 2 and the second groove 3 inner walls are connected with a rotating shaft 4, the outer wall of the rotating shaft 4 is connected with a driven gear 403, and the outer wall of the driven gear 403 is connected with a reciprocating drive mechanism, and each The outer walls of each rotating shaft 4 are connected with a rotating plate 401, and the two rotating plates 401 are respectively set as grid plates with different apertures. Both sides of the outer wall of the rotating plate 401 are connected with a support plate 402, and the two support plates 402 are slidingly connected with a retaining plate. Plate 5, the outer wall of side...

Embodiment 2

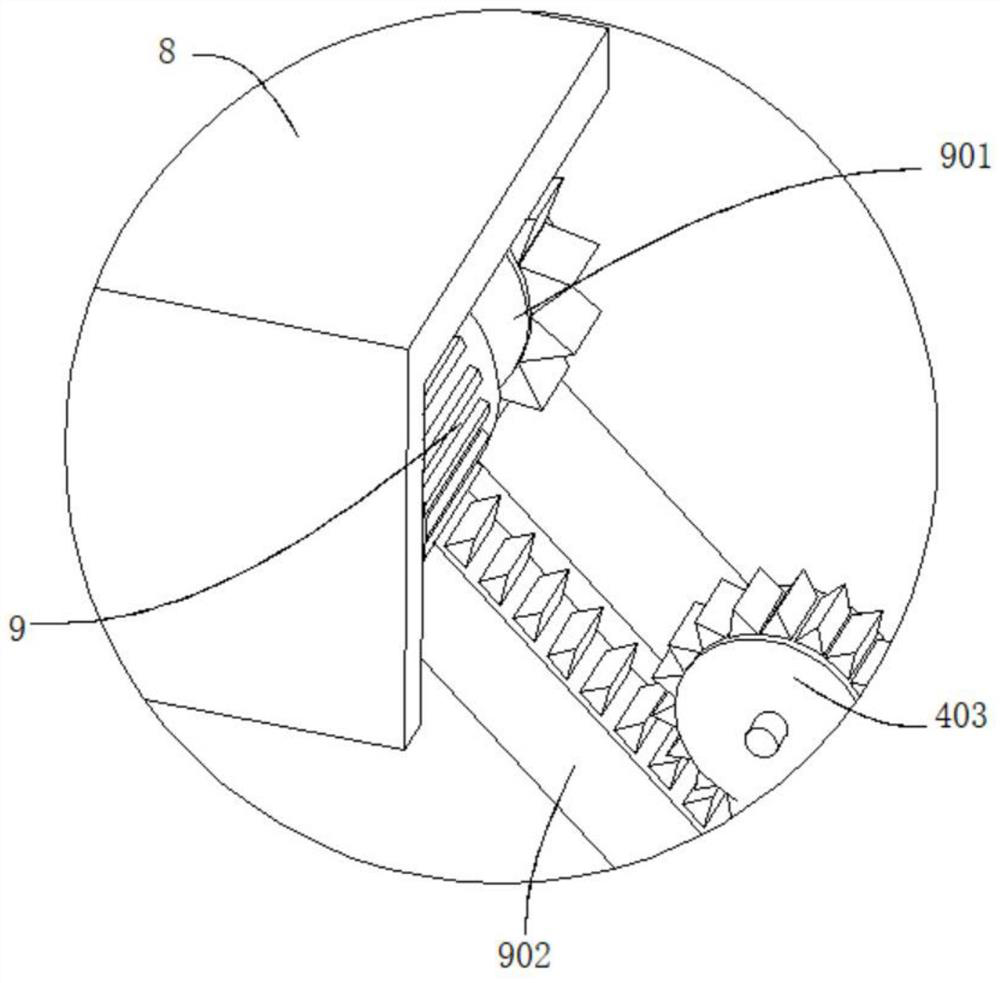

[0040] refer to figure 1 , figure 2 , image 3 with Figure 5 , a subpackaging device for the production of electronic components, which is basically the same as that of Embodiment 1, furthermore, the reciprocating drive mechanism includes an L-shaped plate 8, and the L-shaped plate 8 is fixedly connected to the outer wall of the side plate 101, and the L-shaped The outer wall of the plate 8 is connected with a first motor 9, the output end of the first motor 9 is connected with a driving gear 901, the outer wall of the driving gear 901 is meshed with a rack plate 902, and the rack plate 902 is slidably connected to the outside of the triangular housing 1, and The rack plate 902 is meshed with the driven gear 403 .

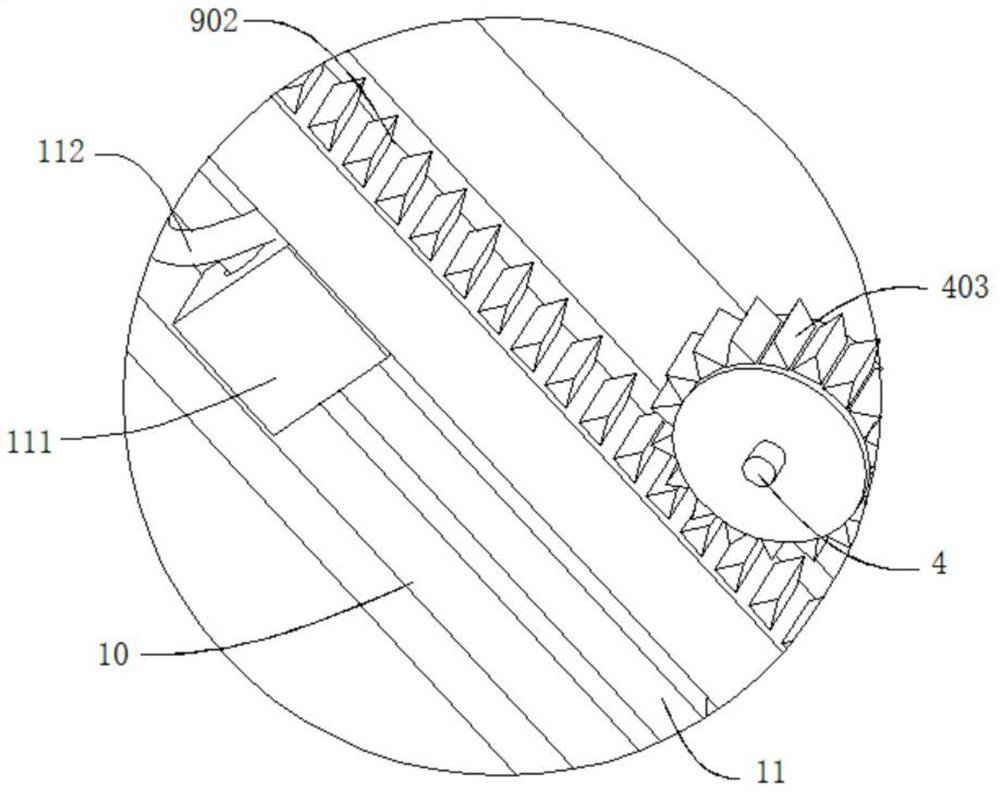

[0041] The outer wall of the triangular housing 1 is connected with a fixed frame 10, and a fixed rod 11 is connected between the inner walls of both sides of the fixed frame 10. The outer wall of the fixed rod 11 is slidably connected with a slider 111, and t...

Embodiment 3

[0044] refer to Figure 1-7 , a subpackaging device for the production of electronic components, which is basically the same as Embodiment 2, furthermore, the outer wall of the support plate 402 is dug with a guide groove 4021, and the inner wall of the guide groove 4021 is connected with a second elastic element 4022, the second The end of the elastic element 4022 away from the inner wall of the guide groove 4021 is connected with a guide bar 4023 , and the guide bar 4023 is fixedly connected to the outer wall of the baffle plate 5 .

[0045] The lifting mechanism includes two groups of conveying rollers, and the two groups of conveying rollers are connected to two fixed plates 6 in rotation respectively. Each group of conveying rollers includes two conveying roller bodies 12, and the outer walls of the four conveying roller bodies 12 are connected with conveyor belts 121, and the conveyor belts The outer wall of 121 is connected with an arc-shaped block 1211 , and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com