Fan-shaped gear backlash adjusting structure

A sector gear and adjusting structure technology, applied in belts/chains/gears, components with teeth, portable lifting devices, etc., can solve the problems of complex structure, wear, stuck, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

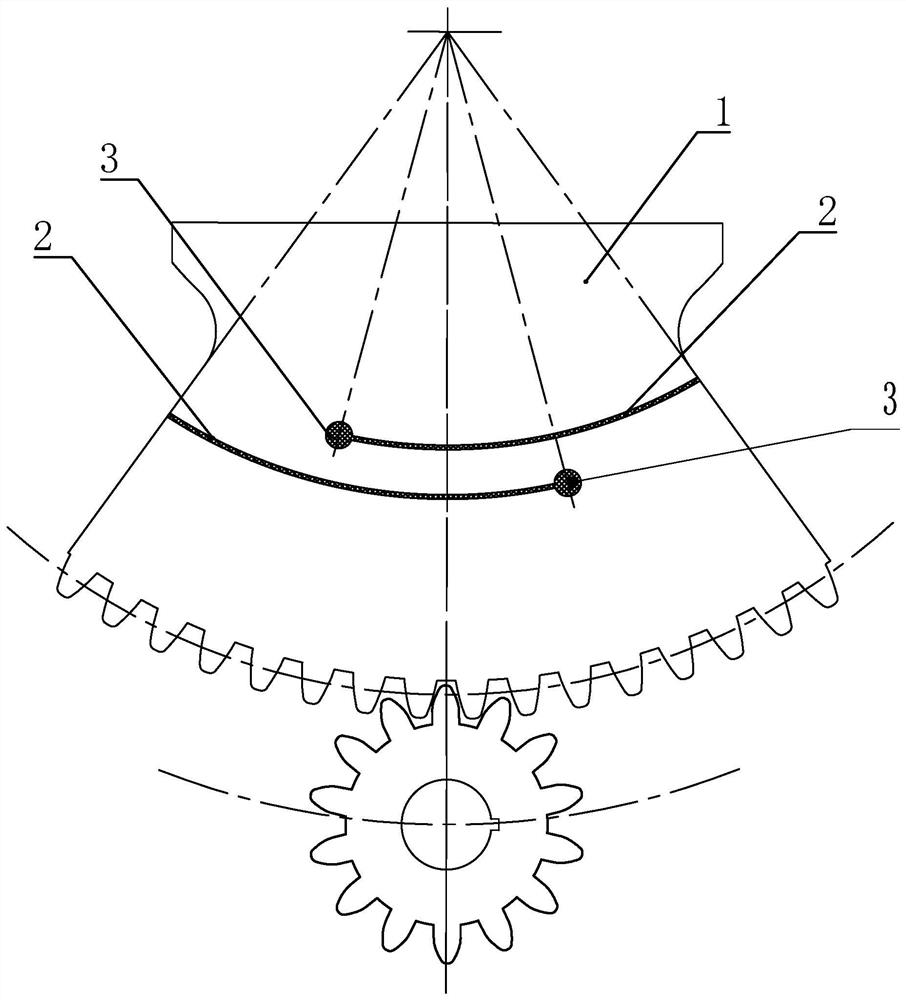

[0019] The general idea of the present invention is to make the sector gear have a certain elastic deformation to form a working principle similar to a spring, and realize the function of adjusting the backlash through the elastic deformation during the gear operation.

[0020] The specific structure is described in detail below with reference to the accompanying drawings:

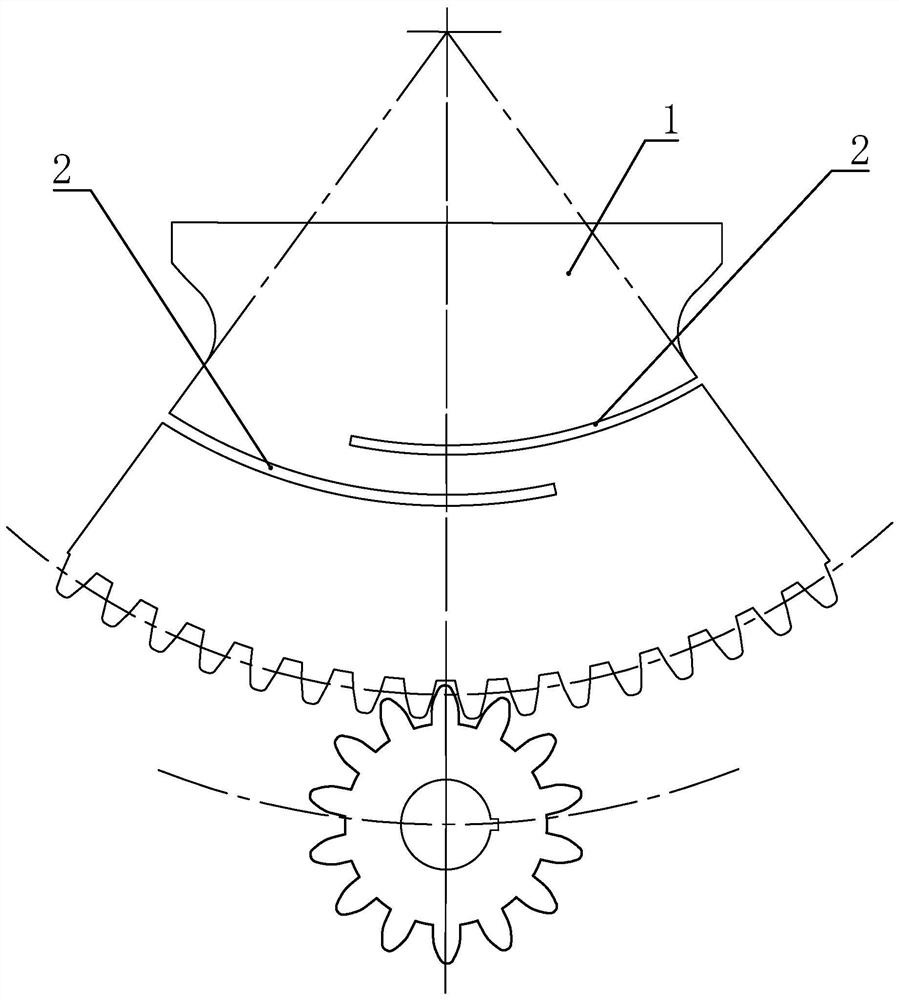

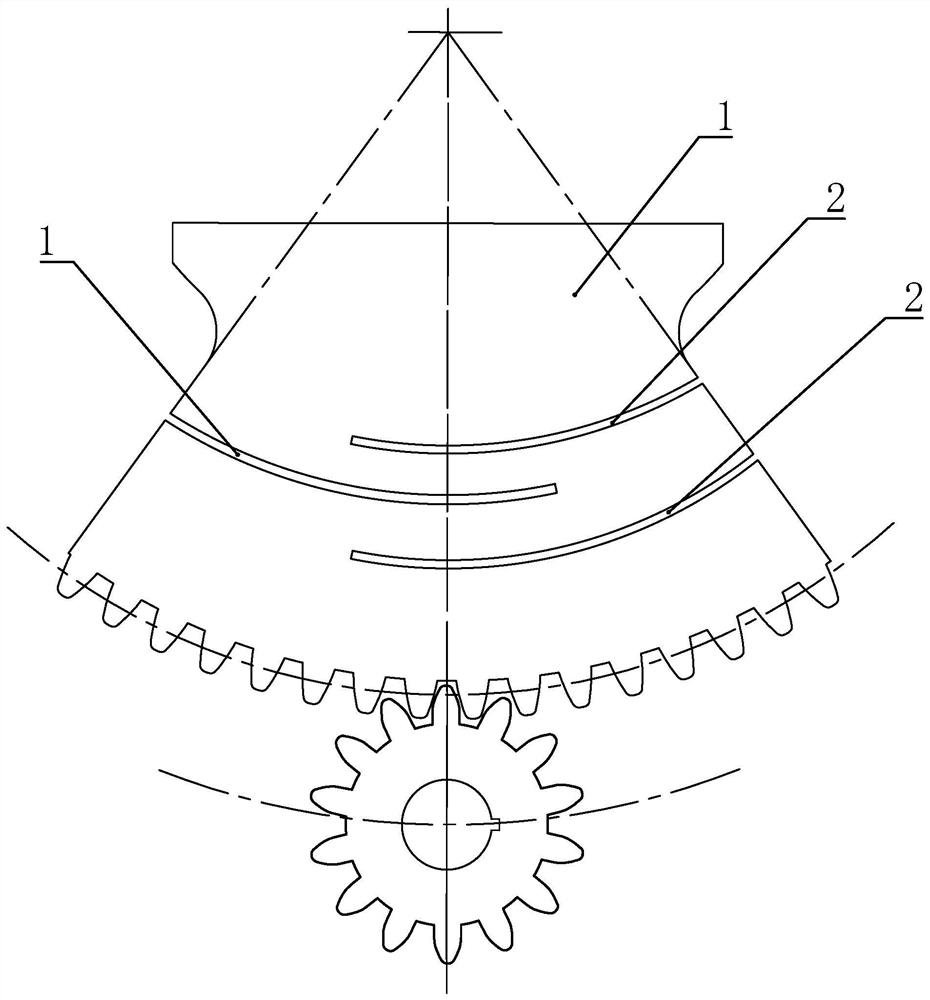

[0021] Such as figure 1 The sector gear 1 shown meshes with the circular gear, and two arc-shaped through grooves 2 are arranged on the end face of the sector gear 1, and one ends of the two arc-shaped through grooves 2 respectively penetrate the two sides of the sector gear 1 in opposite directions, so that the sector The part where the gear 1 is provided with the arc-shaped slot 2 can realize elastic deformation, and then can realize the function of adjusting the backlash of the circular gear and the sector gear 1. These two arc-shaped slots 2 are concentric with the index circle of the sector gear 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com