Vehicle-mounted dynamic weighing system

A dynamic weighing and frame technology, applied in the field of weighing, to achieve the effect of convenient maintenance, lower cost and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The concept of the present invention is to assemble the sensors in the lifting lug to form the lifting lug sensor. The lifting lug sensor is a standard part, which is calibrated after production, so that after loading, it is not necessary to calibrate the whole vehicle, so that It is easy to install and use immediately.

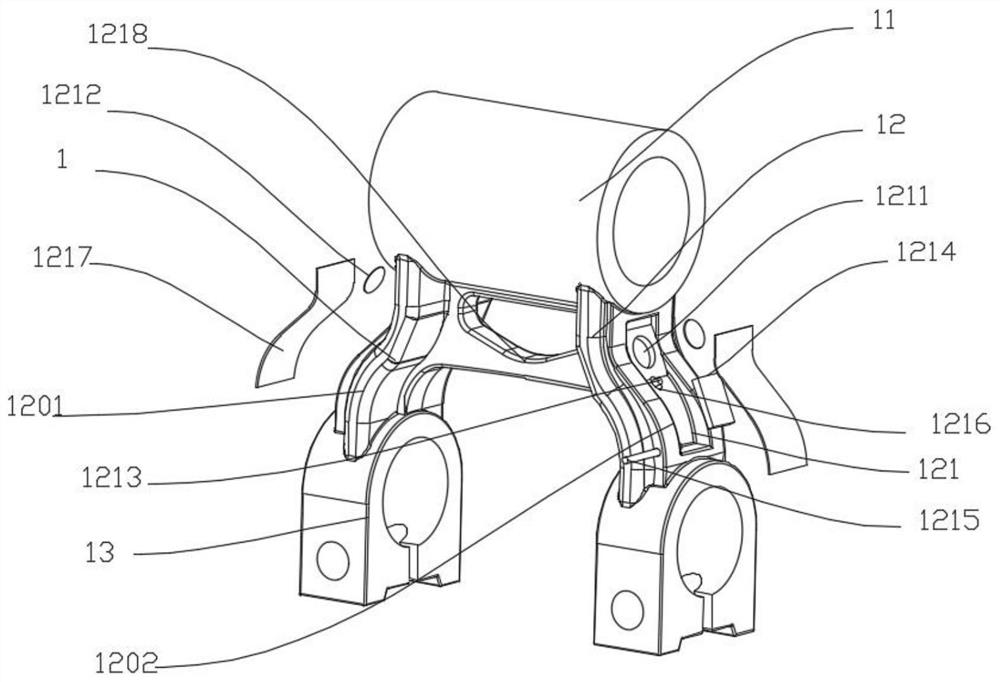

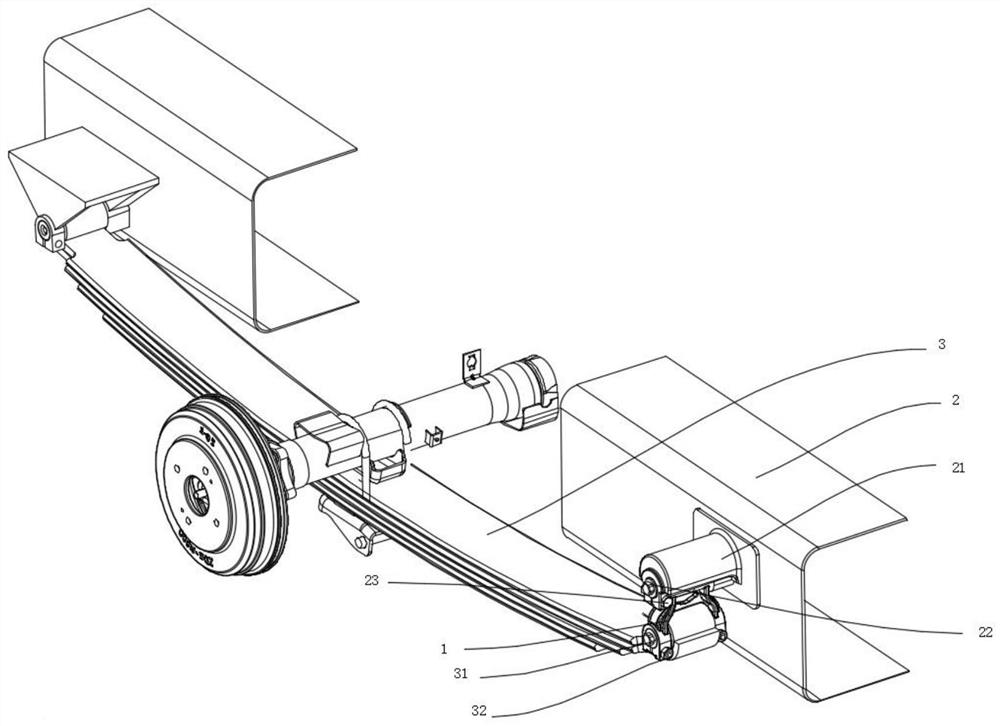

[0026] Such as figure 1 , figure 2 As shown, the present invention discloses a system for vehicle-mounted dynamic weighing, including a vehicle frame 2, one side of the vehicle frame 2 is connected with a lifting lug bracket 21, and the lifting lug bracket 21 is connected to the lifting lug sensor 1 One end is connected, and the other end of the lifting ear sensor 1 is connected to the leaf spring 3. The gravity of the whole vehicle is applied to the frame 2, and the force is transmitted to the leaf spring 3 through the lifting ear sensor 1. The leaf spring 3 then transmits the gravity to the axle and the tire. A strain gauge 1212 is installed in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com