A kind of treatment method and application of electrode waste

A treatment method and electrode slurry technology, applied in the direction of non-aqueous electrolyte battery electrodes, circuits, electrical components, etc., can solve the problems of unfavorable energy conservation and environmental protection, and achieve the effects of easy industrial scale expansion, low operation cost, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

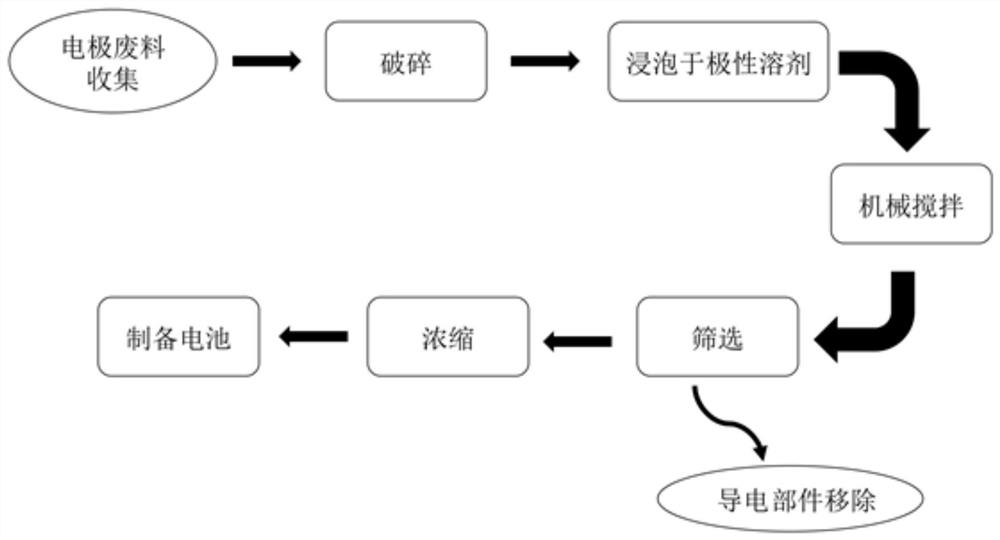

[0106] The preparation and related testing process of electrode waste recycling button half-cells are as follows:

[0107] 1. Preparation of Coin Half Cells

[0108] 1) Preparation of electrode slurry: The collected electrode waste is crushed and immersed in a polar solvent to separate the first conductive metal part or the second conductive metal part, and the obtained slurry is concentrated without adding any other substances Carry out ball milling again for about 2 hours to obtain a slurry for preparing electrodes;

[0109] 2) Coating: the electrode slurry is evenly coated on aluminum foil or copper foil under the action of a knife coater, and then vacuum-dried in the range of about 80°C to about 150°C for about 12 hours;

[0110] 3) Pole piece punching: after the vacuum-dried pole piece is rolled, the pole piece is punched to obtain a pole piece with a diameter of 16mm;

[0111] 4) Preparation of the button half-cell: After the round negative electrode sheet was vacuum-dri...

Embodiment 1

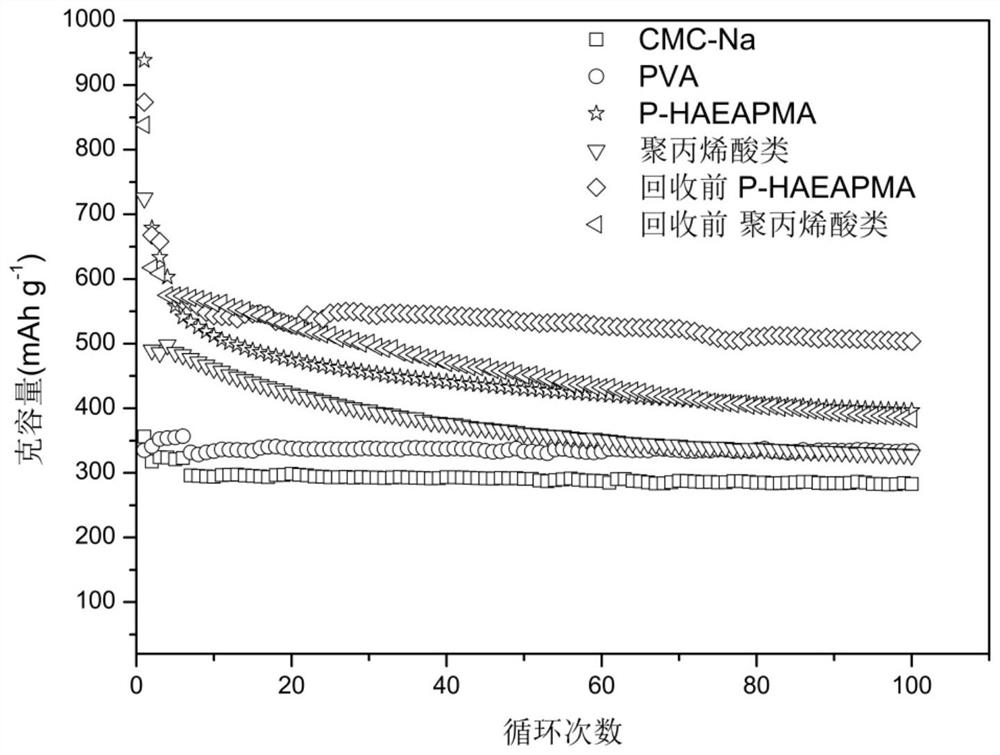

[0121] Negative electrode waste recycling battery preparation

[0122] 1. Electrode waste collection

[0123] The total mass of the electrode material is 2.0g, and 60wt.% of the anode material Si-C (S600, obtained from China Guangdong Betterray New Material Group Co., Ltd.), 20wt.% of the conductive agent carbon black (Super P) and 20wt.% self-made monomer HAEAPMA as a binder (raw material is ethylenediamine and glycidyl methacrylate, and its material ratio is 1:1) is dispersed in 10.0g deionized water, at 25 ℃ Ball milling was performed for 2 hours to form a homogeneous slurry. Next, the slurry was coated on a copper foil as a current collector using a knife coater and cured at 135° C. for 8 hours under vacuum. Collect the entire electrode sheet as electrode waste.

[0124] 2. Electrode waste recycling

[0125] 1) Preparation of electrode slurry: enrich and crush the electrode waste collected above. Crushed lithium-ion battery electrode scrap pieces having a length of ab...

Embodiment 2

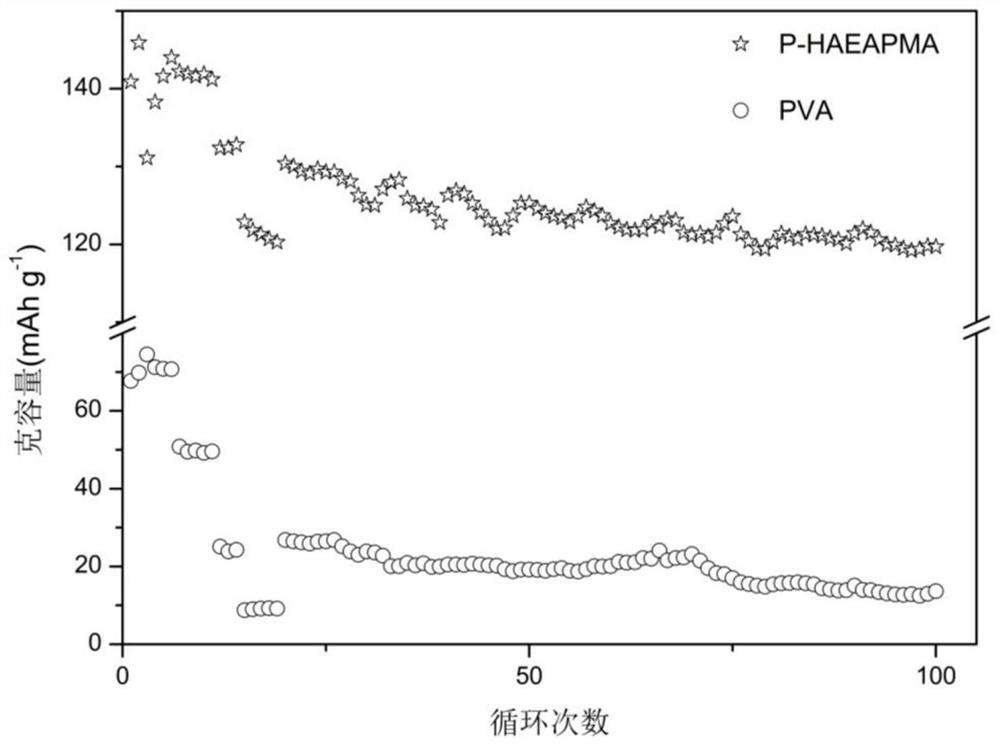

[0131] Positive electrode waste recycling battery preparation

[0132] 1. Electrode waste collection

[0133] The total mass of the electrode material is 2.0g, and 80wt.% of the cathode material LiFePO 4 (obtained from China Xiamen Tungsten Industry Co., Ltd.), 10wt.% conductive agent carbon black (Super P) and 10wt.% self-made monomer HAEAPMA as a binder (raw materials are ethylenediamine and glycidyl methacrylate ester, and its substance ratio is 1:1) was dispersed in 5.0 g of deionized water, and ball milled at 25° C. for 2 hours to form a uniform slurry. Next, the slurry was coated on an aluminum foil as a current collector using a knife coater and cured at 135° C. for 8 hours under vacuum. Collect the entire electrode sheet as electrode waste.

[0134] 2. Electrode waste recycling

[0135] 1) Preparation of electrode slurry: enrich and crush the electrode waste collected above. Crushed lithium-ion battery electrode scrap pieces having a length of about 1.0 cm to abou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com