Fault monitoring method of explosion-proof motor

An explosion-proof motor and fault monitoring technology, applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve problems such as unfavorable promotion and application, damage to the motor, and impact on service life, and achieve easy promotion and application, strong anti-drying performance, and structural simplified effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiment of the present invention will now be described in conjunction with the accompanying drawings.

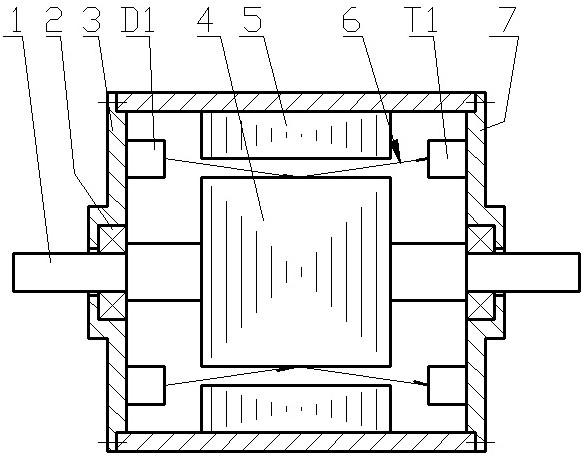

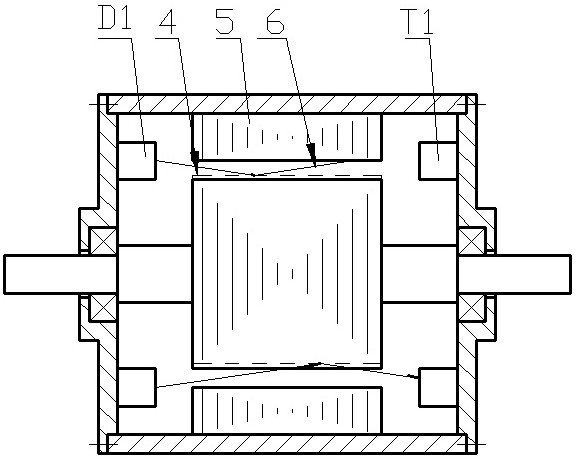

[0012] A fault monitoring method for an explosion-proof motor, such as figure 1 As shown, the light-emitting diode D1 of the photoelectric sensor GE is installed on the front cover 3 of the explosion-proof motor, the phototransistor T1 of the photoelectric sensor GE is installed on the rear end cover 7 of the explosion-proof motor, and the light beam emitted by the light-emitting diode D1 passes through the gap between the stator and the rotor. The air gap between reaches the phototransistor T1.

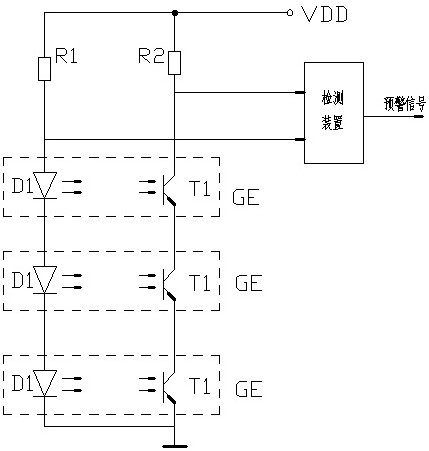

[0013] A detection device judges the state signal of the phototransistor T1 and the tube voltage drop signal of the light-emitting diode D1. The detection circuit is as follows: image 3 As shown, the collector of the phototransistor T1 is connected to the DC power supply VDD through the resistor R2, the emitter of the phototransistor T1 is grounded, the ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com