An all-round painting machine for ring parts of new energy vehicles

A new energy vehicle, all-round technology, applied in the direction of injection devices, etc., can solve the problems of inaccurate placement of accessories, troublesome rotation of accessories, damaged accessories, etc., to achieve the effect of convenient rotation of accessories, quality assurance, and accurate placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

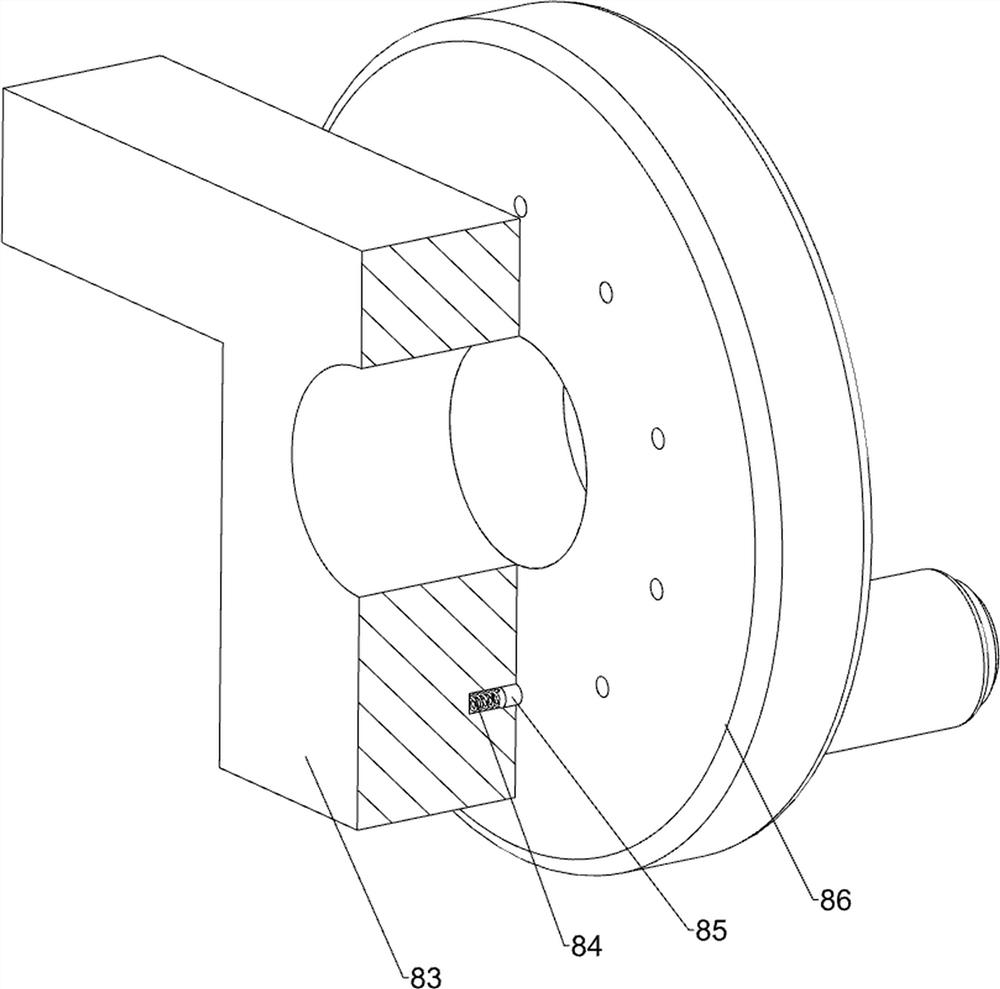

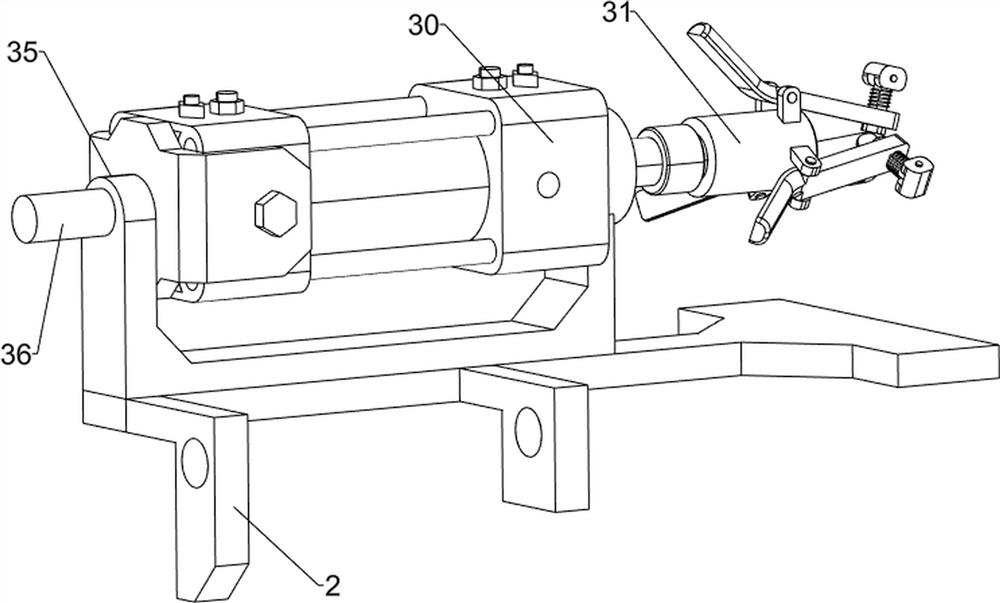

[0031] An all-round painting machine for ring parts of new energy vehicles, such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, it includes a support 1, a support plate 2, a clamping mechanism 3 and a spraying mechanism 4. The upper part of the support 1 is connected with a support plate 2, the left side of the upper part of the support plate 2 is provided with a clamping mechanism 3, and the right side of the lower part of the support 1 is provided with There are spraying mechanism 4.

[0032] The clamping mechanism 3 includes a cylinder 30, a guide sleeve 31, a first connecting rod 32, a first spring 33, a top block 34, a mounting seat 35 and a first rotating shaft 36, and the left side of the upper part of the support plate 2 is connected with the mounting seat 35. The left side of the seat 35 top is rotatably connected with a first rotating shaft 36, and the right side of the first rotating shaft 36 is equipped with a cylinder 30. Guide sleeve ...

Embodiment 2

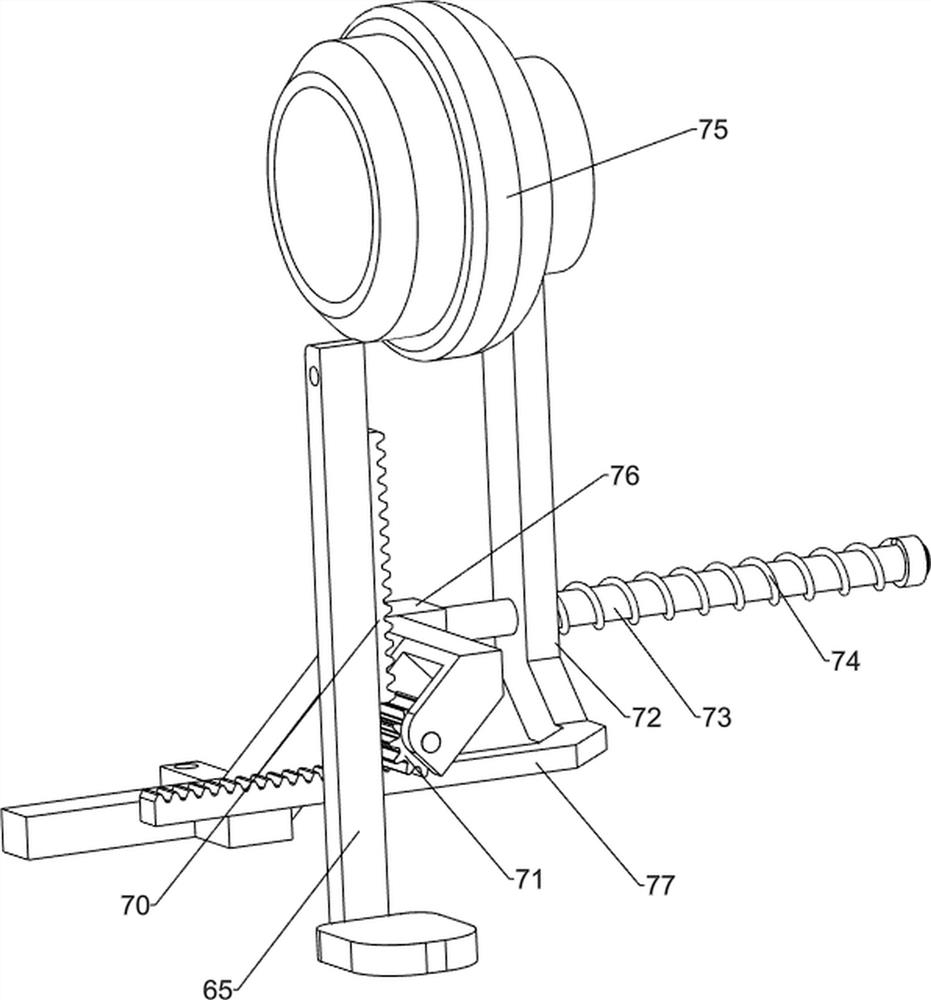

[0036] On the basis of Example 1, such as figure 1 , Figure 6 , Figure 7 , Figure 8 , Figure 9 and Figure 10 As shown, a fixed assembly 5 is also included, and the fixed assembly 5 includes a third support block 50, a roller 51, a limit rod 52, a first runner 53, a second runner 54 and a second spring 55, and the upper part of the support plate 2 The right side is connected with a third support block 50, and the right side of the third support block 50 is rotationally connected with a first runner 53, and the first runner 53 is evenly spaced and connected with three stop rods 52, between the three stop rods 52 There is a second runner 54 slidingly connected between them, the second runner 54 cooperates with the first connecting rod 32, the second runner 54 is connected with the third support block 50 in rotation, the second runner 54 is connected with the first runner Between 53, three second springs 55 are connected evenly at intervals, and the second spring 55 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com