Rear longitudinal beam assembly and vehicle

A rear longitudinal beam and assembly technology, which is applied to vehicle parts, upper structure sub-assemblies, upper structure, etc., can solve the problems of low shock absorber arrangement height, poor rear longitudinal beam manufacturability, low structural strength, etc., and achieve increased Highly arranged space, good versatility, and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings.

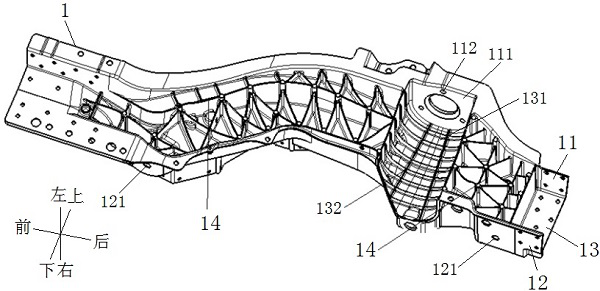

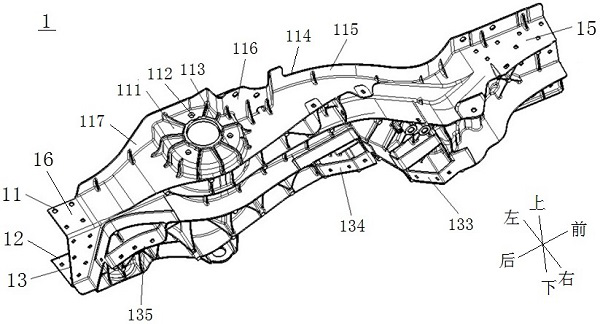

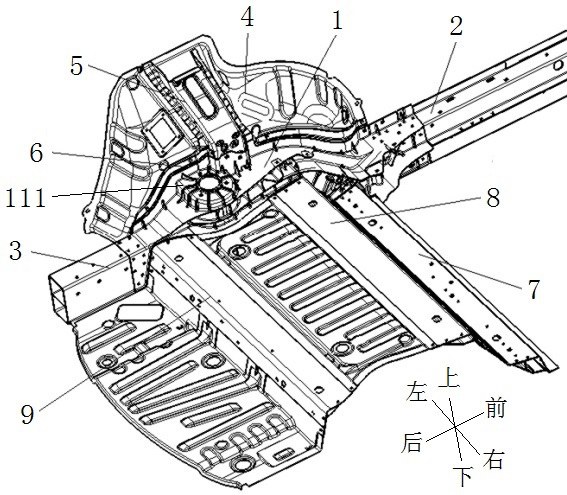

[0022] see Figure 1 to Figure 3 , the rear longitudinal beam assembly shown in , including the rear longitudinal beam body 1 formed by casting aluminum alloy, reduces the weight of the rear longitudinal beam assembly on the premise of meeting the structural strength performance requirements, and realizes the lightweight of the vehicle body.

[0023] As shown in the figure, the rear side beam body 1 is located on the left side of the vehicle, the left side is the outside of the vehicle, and the right side is the inside of the vehicle. The top plate 11 and the side plate 13 of the bottom plate 12, the middle section of the top plate 11 is integrally formed with an upwardly extending mounting protrusion 111, and the mounting protrusion 111 is provided with three first mounting holes 112 for fixing the shock absorber and A plurality of first reinforcing ribs 113 run th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com