Automobile carpet rapid carrying tool

A technology for car carpets and porters, applied in the direction of lifting devices, etc., can solve the problems of low transfer efficiency and high labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

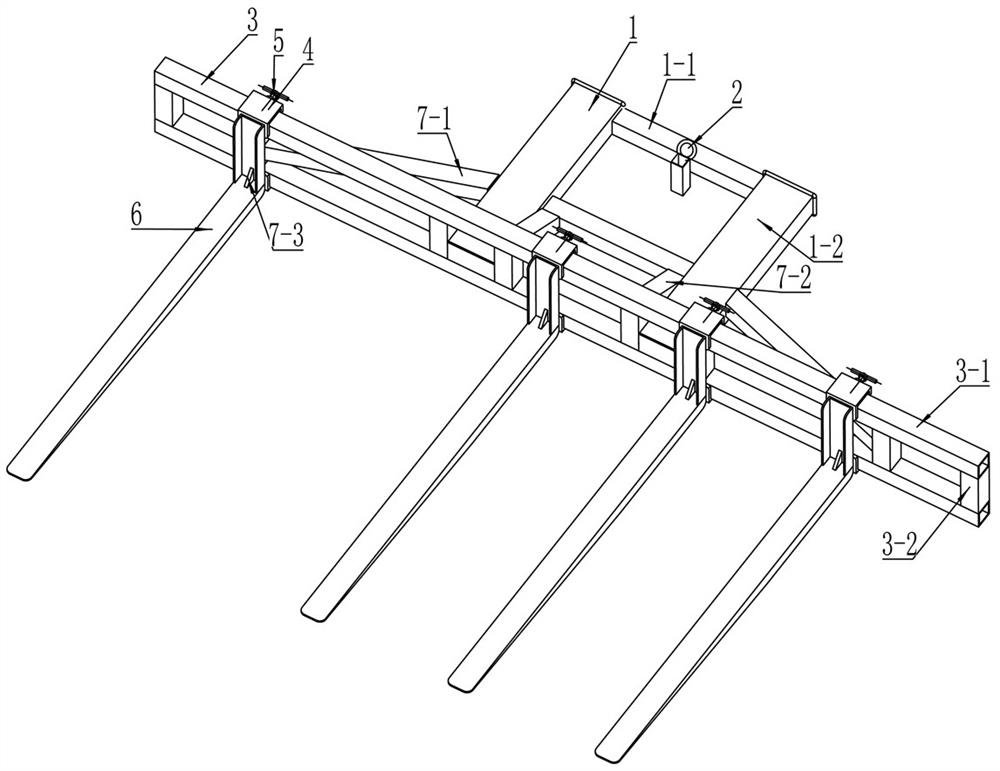

[0016] Embodiments of the present invention are described in further detail below in conjunction with the accompanying drawings:

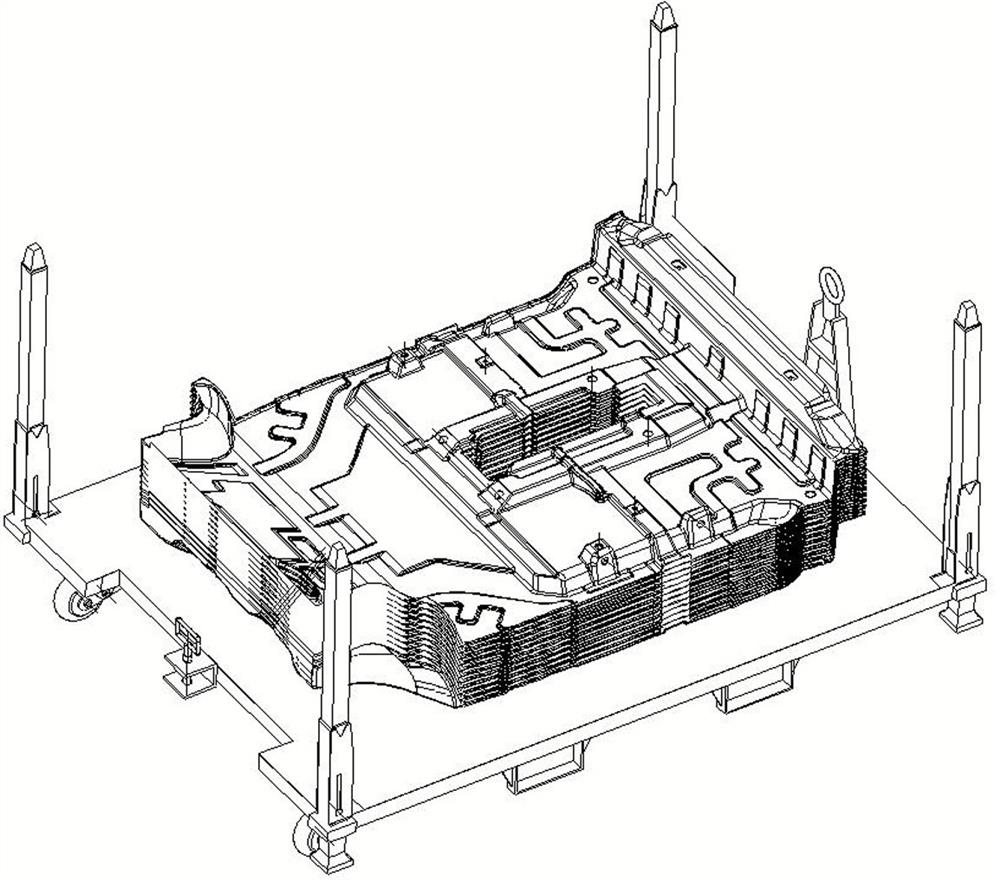

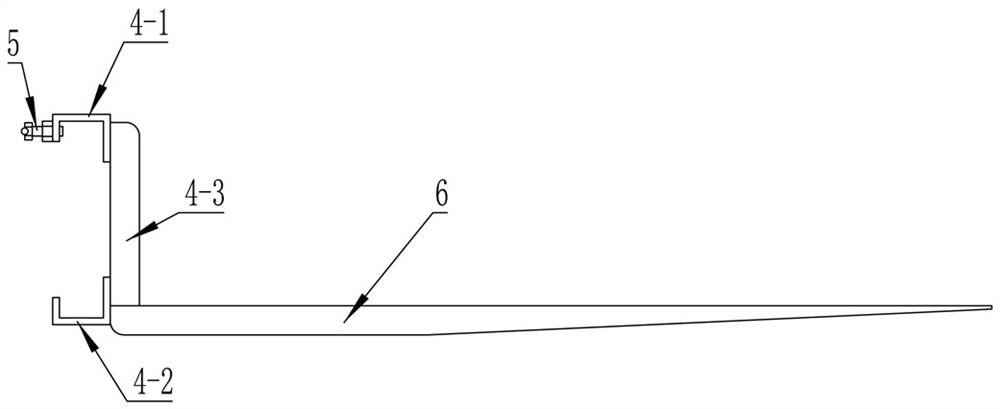

[0017] like figure 2 , image 3 The shown car carpet fast moving tooling includes a mounting base 1 with hanging lugs 2 on one side. A beam 3 is provided on the side of the base 1 away from the mounting lug 2. The beam 3 includes two upper and lower beams 3-1 and multiple vertical beams 3-2 between the beams. The mounting lug 2 is located on the installation base 1 away from the beam. The middle part of the crossbar 1-1 on one side; the side of the crossbeam 3 facing away from the installation base 1 is provided with a plurality of longitudinally movable forks 6 side by side, and each longitudinally movable fork 6 is movably connected with the crossbeam 3 through a sliding sleeve 4, and the sliding The cover 4 is provided with locking bolts 5, and the thickness of each longitudinal movable fork 6 gradually decreases from the end connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com