Drying device for cloth dyeing

A drying device and cloth technology, which is applied to the configuration of textile material equipment, the processing of textile material carriers, and the removal of liquid/gas/steam by air jet method, etc. It can solve the problem of lack of deodorization of cloth, decrease of cloth service life, and affect the use effect and other problems, to achieve the effect of convenient transmission, improved stability, and convenient discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

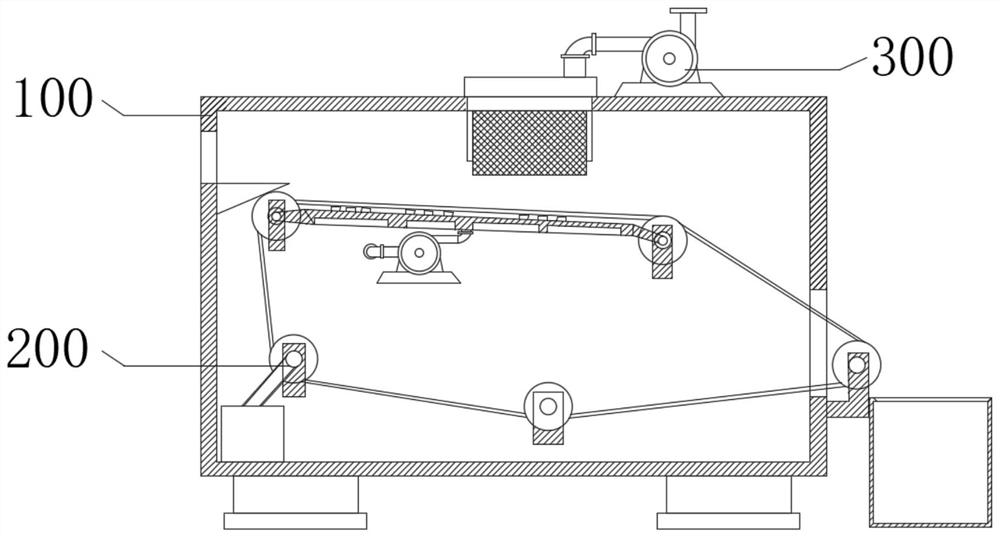

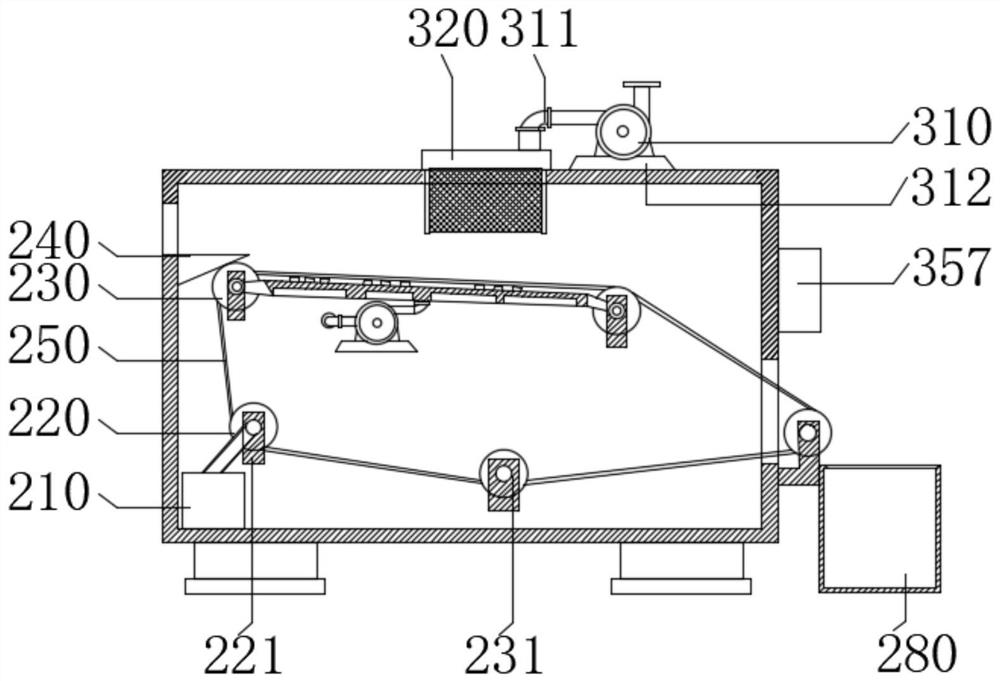

[0028] see Figure 1-4 , the present invention provides a technical solution: a drying device for fabric dyeing includes a base 100, a transmission assembly 200 and a drying assembly 300, and the base 100 is used to support and fix the transmission assembly 200 and the drying assembly 300, so as to facilitate transmission The assembly 200 and the drying assembly 300 dry the cloth.

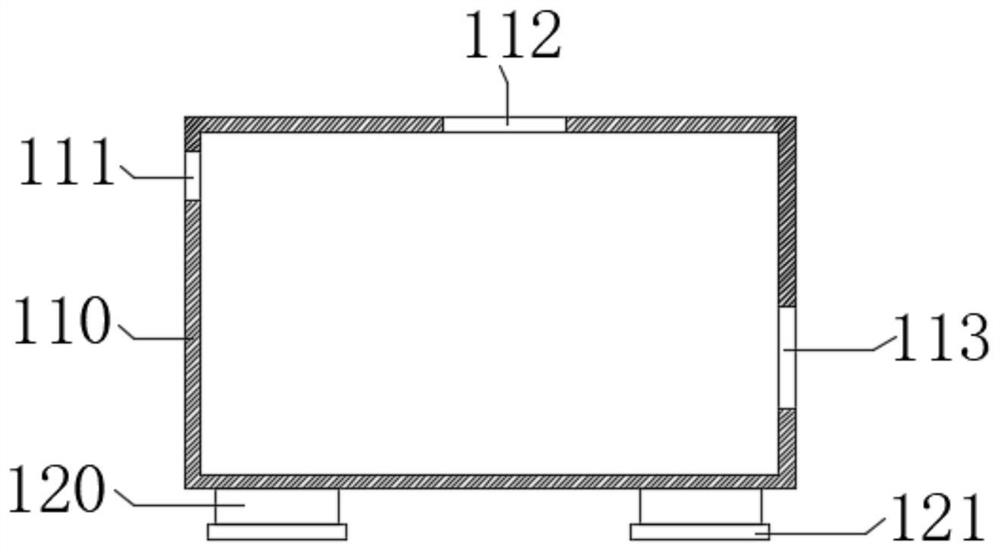

[0029] see figure 1 and figure 2 , the base 100 includes a box body 110 and support legs 120, which are evenly arranged at the four corners of the box body 110, and the support legs 120 are fixedly connected to the four corners of the box body 110 by welding, so as to facilitate the support and fixation of the four corners of the box body 110, and one side of the box body 110 is set There is a material inlet 111, which is convenient for the outside to put the cloth to be processed into the inside of the box body 110. The side of the box body 110 close to the material inlet 111 is provided with a...

Embodiment 2

[0033] see Figure 1-4 , the present invention provides a technical solution: a drying device for fabric dyeing includes a base 100, a transmission assembly 200 and a drying assembly 300, and the base 100 is used to support and fix the transmission assembly 200 and the drying assembly 300, so as to facilitate transmission The assembly 200 and the drying assembly 300 dry the cloth.

[0034] see figure 1 and figure 2 , the base 100 includes a box body 110 and support legs 120, which are evenly arranged at the four corners of the box body 110, and the support legs 120 are fixedly connected to the four corners of the box body 110 by welding, so as to facilitate the support and fixation of the four corners of the box body 110, and one side of the box body 110 is set There is a material inlet 111, which is convenient for the outside to put the cloth to be processed into the inside of the box body 110. The side of the box body 110 close to the material inlet 111 is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com