Method for dismantling three-rock-pillar support of huge-span underground cave depot

A technology that spans ground and caverns. It is applied in the field of dismantling the support of three rock pillars in giant-span underground caverns. It can solve the problems of affecting the use effect and the influence of beams and columns on the spatial layout of caverns, and achieve the effect of speeding up the construction progress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

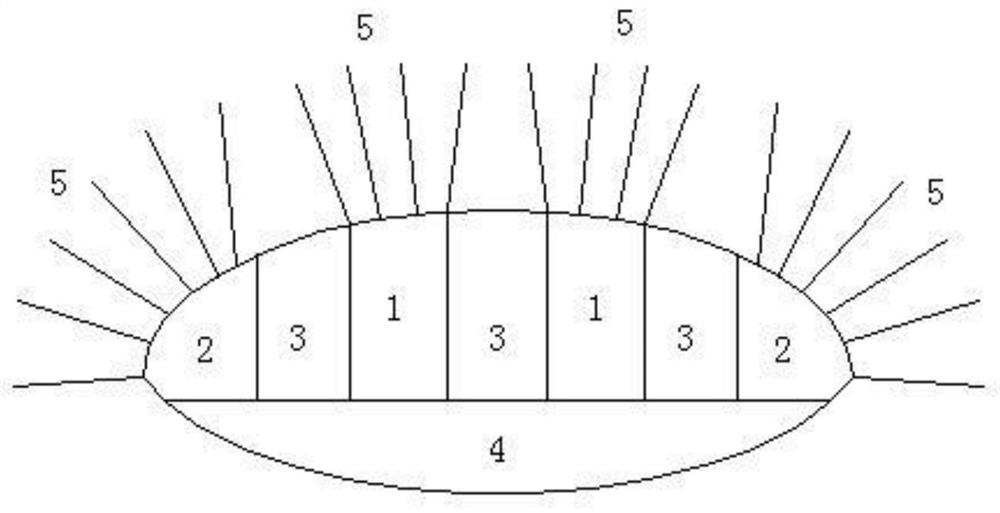

[0020] The invention discloses a method for removing the support of three rock pillars in a huge-span underground cavern. In the invention, the giant-span underground cavern refers to an underground cave with a span of more than 20 meters. Due to the complexity of the underground rock mass, in some areas, the stability of the rock mass is very poor, and the possibility of collapse is high when the underground cavern is excavated.

[0021] The method in the present invention is applicable to areas with large-span underground caverns and rock mass stability is relatively poor, specifically as follows:

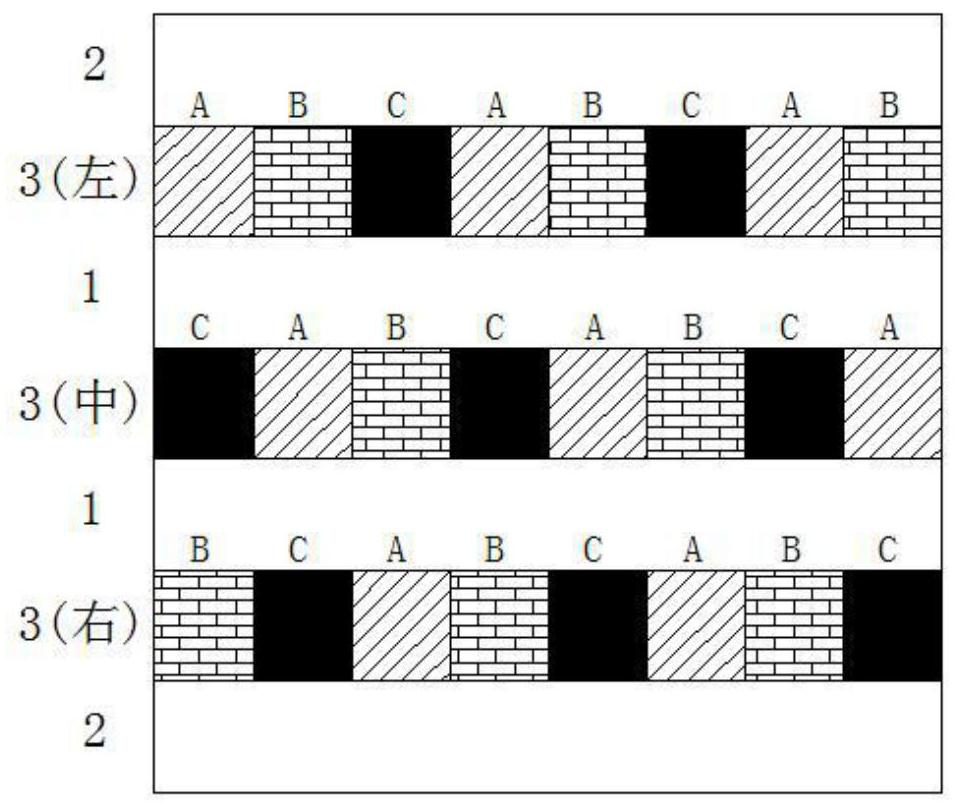

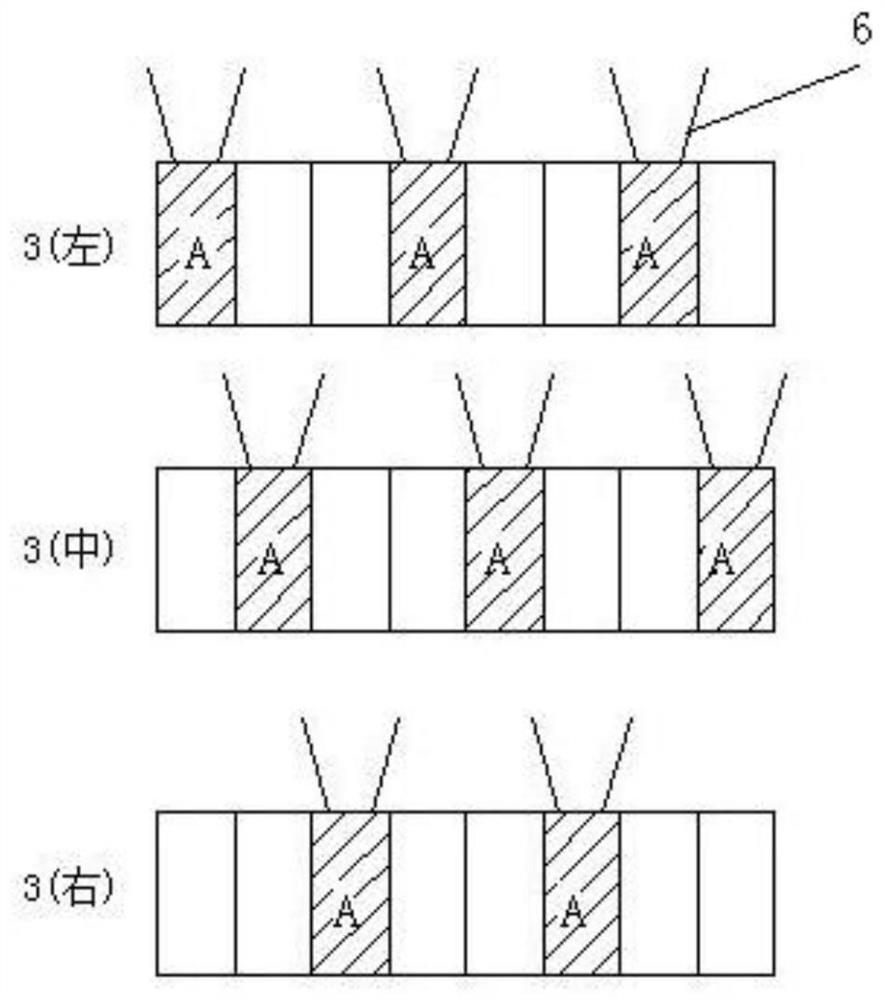

[0022] Step 1. Divide the area: Divide the working face of the underground cavern to be excavated into the upper cavern area and the lower cavern area 4, and then divide the upper cavern area into three areas in the left and right direction, which are located in the upper cavern area. The left or right edge of the chamber area is the side cave area 2; the middle area of the upp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com