Solid rocket engine elasticity weak constraint test rack

A technology of solid rockets and motors, which is applied in the direction of rocket motor devices, machines/engines, mechanical equipment, etc. It can solve problems such as processing errors, mutual interference between installations, failure to achieve test goals, etc., achieve small mutual interference, ensure position accuracy and safety Reliability, the effect of realizing precise and precise positioning and reliable limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention is further described in conjunction with accompanying drawing and specific embodiment:

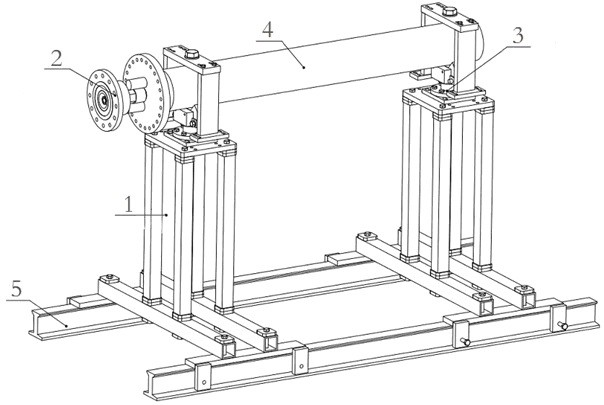

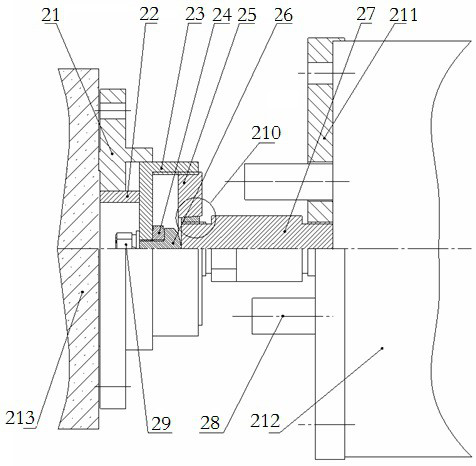

[0024] The overall device of the present invention is composed of ground guide rails, a fixed frame, a moving frame, a test engine, and an adjustment device, such as figure 1 shown.

[0025] In order to meet the requirements of test accuracy, a special design of the test bench is required. Including rational determination principles, test bench structure design, test bench installation and debugging methods, etc. The design criteria for the test bench are:

[0026] The bench has a high natural frequency, which ensures the stability of the dynamic characteristics of the engine during work; the interference between the moving frame constraints is small; ensures the safety and reliability of the engine during installation and work; With small displacement movement space.

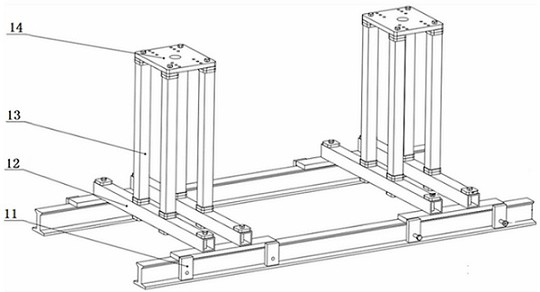

[0027] The frame fixing device is composed of underframe, beam, column, bracket plate, l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com