Super-miniature rotor dynamic balancing measuring method and equipment for complementing the same

A technology of ultra-miniature rotor and measurement method, which is applied in the field of ultra-miniature rotor dynamic balance measurement method and the equipment implementing the method, which can solve the problems of difficult separation of unbalanced signals, small signals, and low balance speed, and improve the signal-to-noise ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

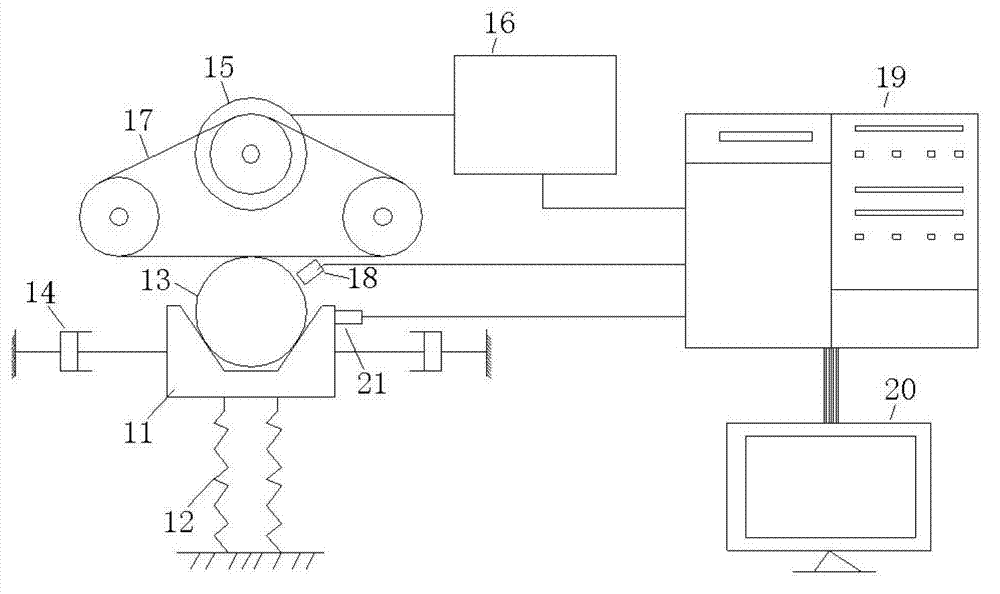

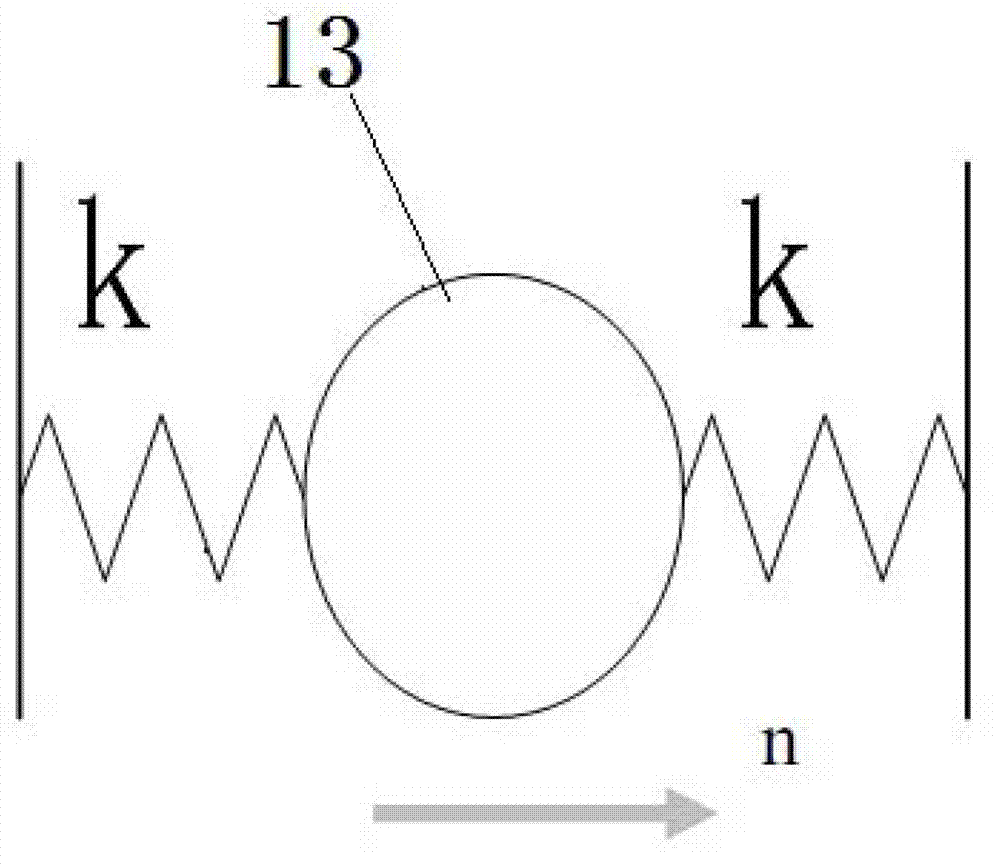

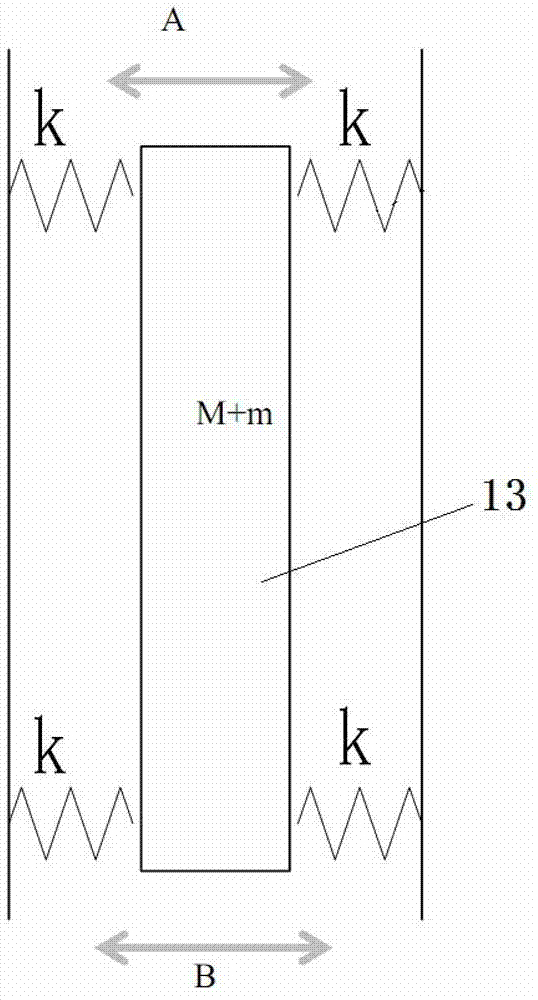

[0033] Embodiment 1 of the ultra-miniature rotor dynamic balance measuring method of the present invention, as Figure 1-5 As shown, the following steps are included: 1) Install a single-degree-of-freedom damping device on the support device for supporting the ultra-micro rotor to be tested, and place the support device at the resonance point of the dynamic balancing machine. In this embodiment, The support device includes a V-shaped support block 11 and a support member 12 located at the bottom of the support block. The stiffness of the support member 12 is adjustable. In this embodiment, the support member 12 adopts a thin sheet soft spring, and there are two support devices. The two supporting devices are sequentially arranged along the axial direction of the ultra-miniature rotor 13 to be tested. In this embodiment, the damping device adopts an oil damper 14, and the damping devices are respectively located on both sides of the supporting device. Figure 2-3 The supporting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com