Decompression devices for marine emergency breathing systems

A decompression device and breathing system technology, which is applied in the direction of respiratory protection devices, breathing filters, respiratory protection containers, etc., can solve the problems of limited adaptability, large space occupation, and difficulty in fully staffing, etc., to achieve The effect of small external environment influence, high reliability and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

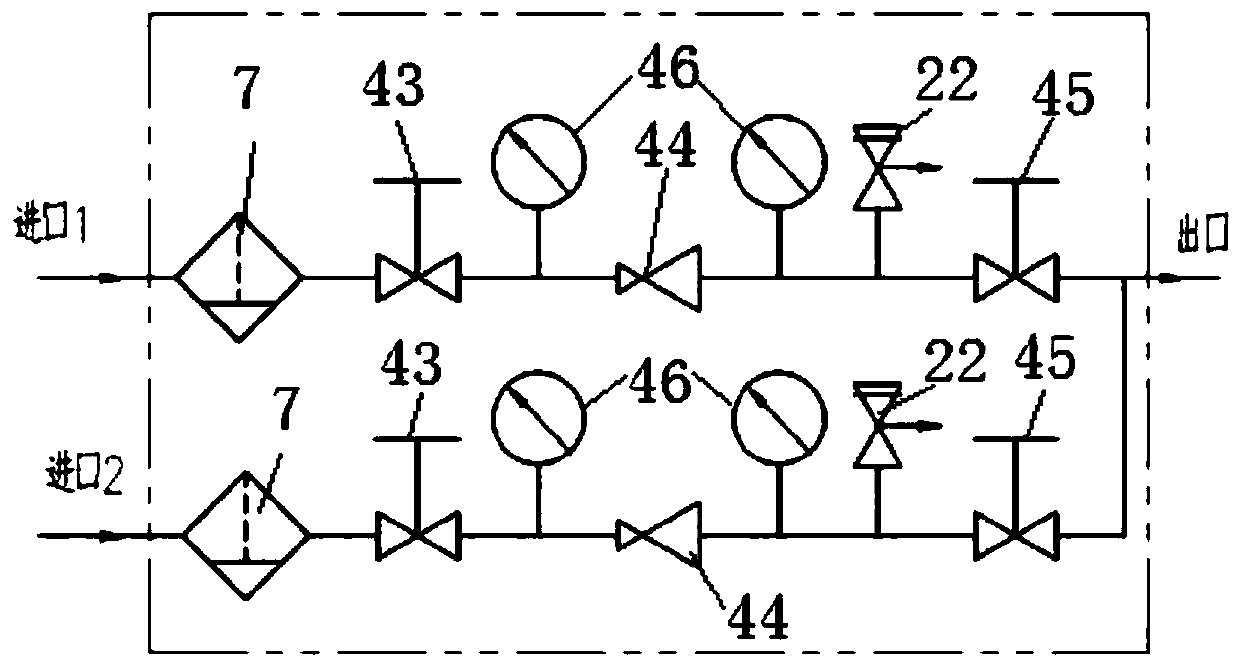

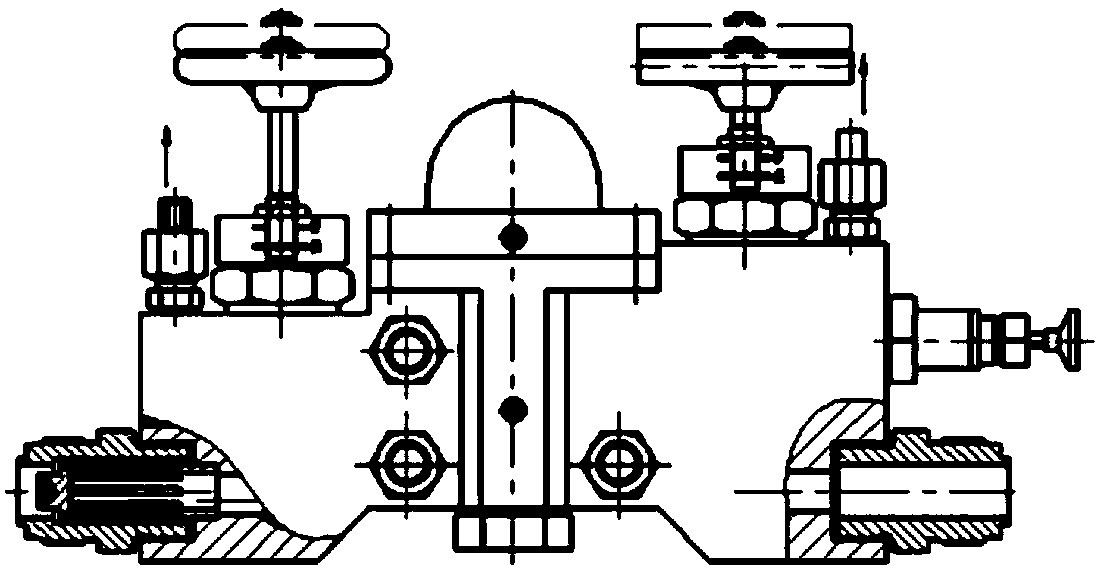

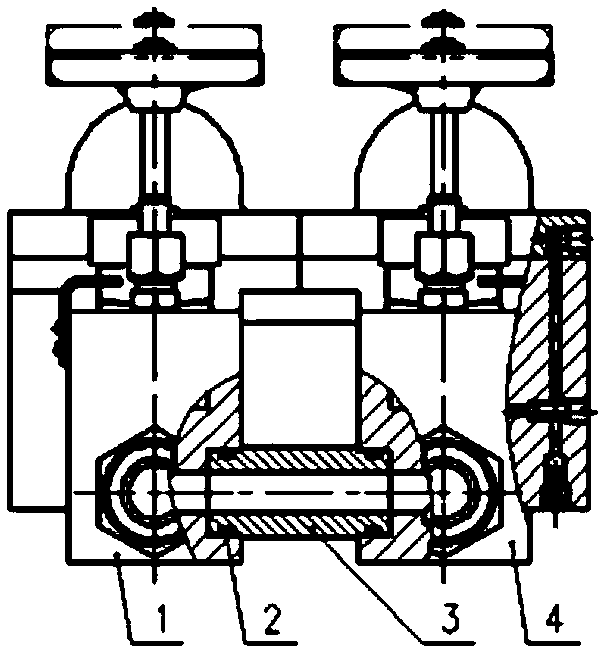

[0027] Such as figure 1 As shown, a decompression device used for the emergency breathing system in the cabin of a ship has two groups of valve groups, and the inlet and outlet ports of each group of valve groups pass through the filter element 7, the inlet shut-off valve assembly 43, and the pressure relief valve assembly in sequence. 44. The outlet cut-off valve assembly 45 is connected with each other. The pressure gauge 46 is installed on the inlet and outlet pipes of the pressure reducing valve assembly 44 , and the safety valve 22 is installed on the inlet pipe of the outlet cut-off valve assembly 45 .

[0028] The working principle of the decompression device: the inlet ends of the two groups of valve groups can be connected to an air pipeline separately, and each group of valve groups includes a filter 7, an inlet stop valve assembly 43...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com