Internal circulating multi-stage centrifugal water pump

A centrifugal water pump and internal circulation technology, which is applied in the direction of pumps, pump components, non-variable pumps, etc., can solve problems such as damage to multi-stage centrifugal water pumps, dumping, and unstable placement of multi-stage centrifugal water pumps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

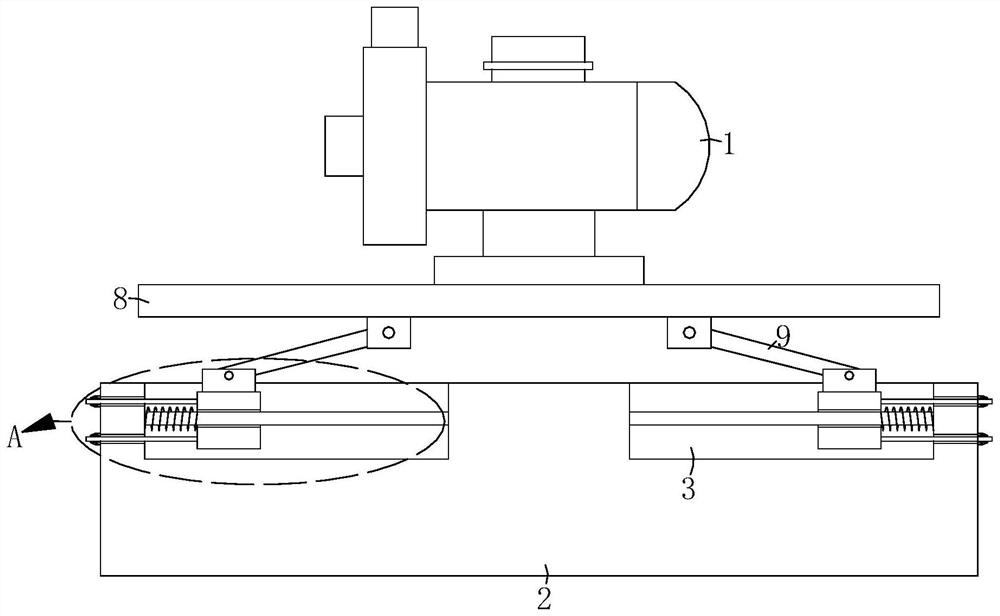

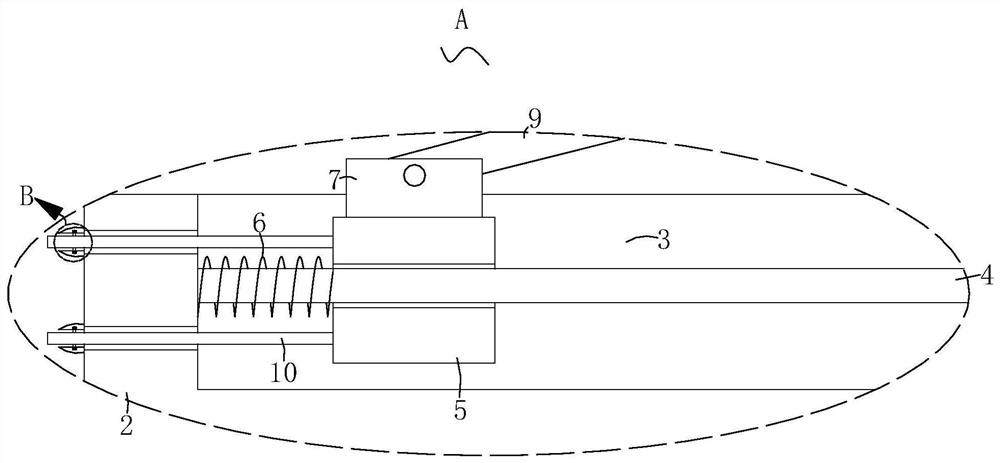

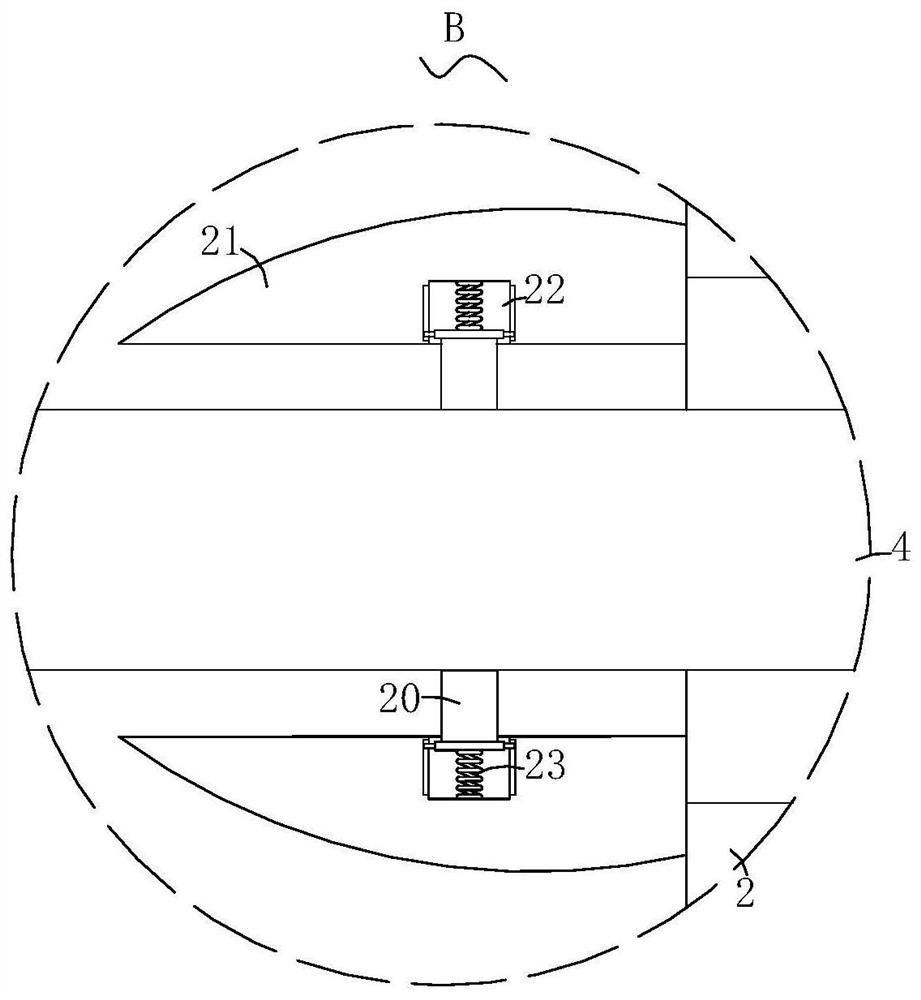

[0030] Please refer to Figure 1-Figure 6, in the first embodiment of the present invention, the internal circulation multistage centrifugal water pump includes: a water pump 1 and a base 2, the base 2 is arranged below the water pump 1; two installation grooves 3, two installation grooves 3 Both are set on the top of the base 2; two fixed rods 4 are respectively fixedly installed on the inner walls of the two installation grooves 3; two sliders 5, two sliders 5 are respectively sleeved on the two fixed rods 4; two first springs 6 are respectively sleeved on the two fixed rods 4, and the two first springs are respectively sleeved on the two fixed rods 4. One end of 6 is fixedly connected with the inner walls of the two mounting grooves 3 respectively, and the other ends of the two first springs 6 are respectively fixedly connected with the outer walls of the two sliders 5; two mounting seats 7, two The mounting base 7 is respectively fixedly installed on the tops of the two s...

no. 2 example

[0041] Based on the internal circulation multistage centrifugal water pump provided in the first embodiment of the present application, the second embodiment of the present application proposes another internal circulation multistage centrifugal water pump. The second embodiment is only a preferred mode of the first embodiment, and the implementation of the second embodiment will not affect the independent implementation of the first embodiment.

[0042] The second embodiment of the present invention will be further described below in conjunction with the drawings and implementation methods.

[0043] Please refer to Figure 7-Figure 9 , the inner circulation multistage centrifugal water pump also includes four sliding grooves 24, the four sliding grooves 24 are all opened on the bottom of the base 2, and the inner walls of the four sliding grooves 24 are all slidably installed with sliding Moving block 25, the bottoms of four described sliding blocks 25 are all hingedly equip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com