Sieve pore deviation checking device and checking method

A sieve hole and deviation technology, applied in the field of test sieves, can solve the problems of heavy work and low efficiency, and achieve the effects of simple maintenance, avoiding cumbersome operations and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

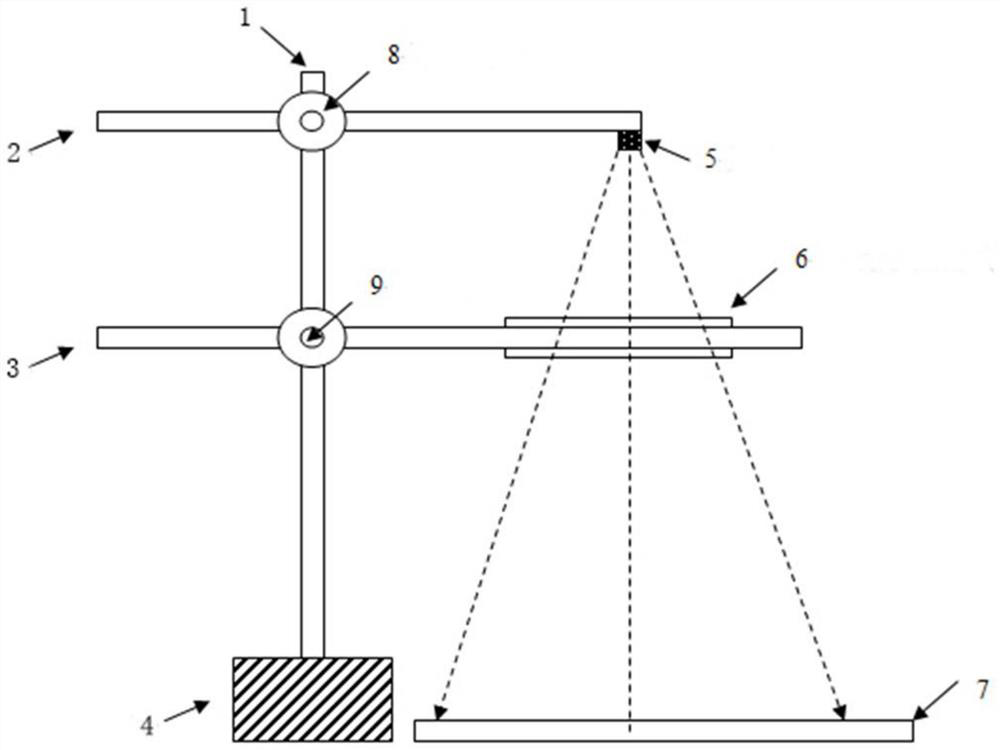

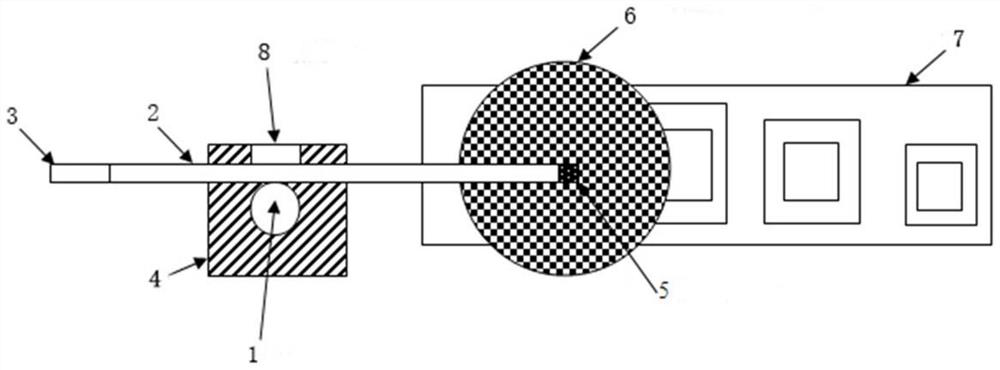

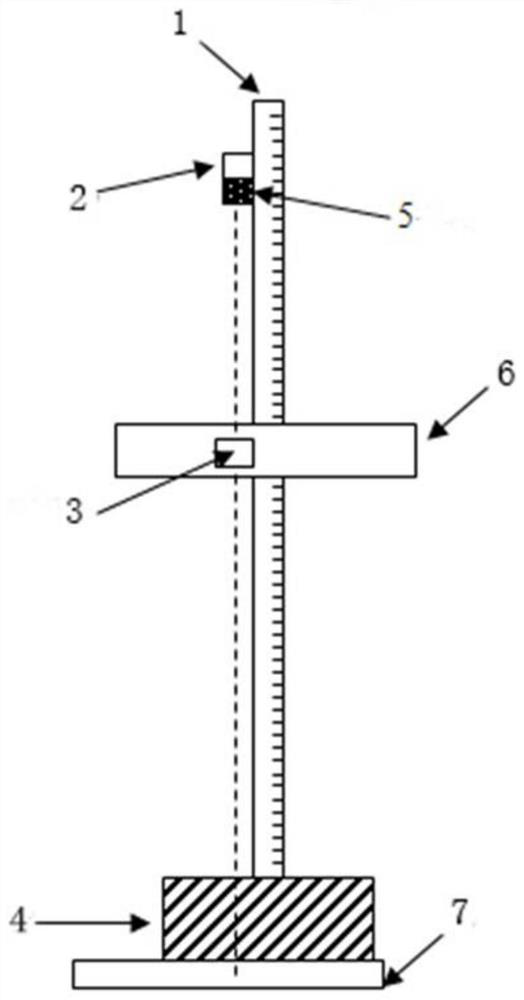

[0034] Such as Figure 1 to Figure 6c As shown, the present embodiment provides a sieve hole deviation checking device, including: a column 1 vertically installed on a base 4 , an adjustable bracket, a size deviation standard plate 7 and a light source 5 . Wherein, the adjustable bracket includes an upper bracket 2 and a lower bracket 3, both of which are movably installed on the column 1, and can be adjusted front and rear, left and right, up and down relative to the column 1. The light source 5 is installed on the upper bracket 2, the test sieve 6 is installed on the lower bracket 3, and the size deviation standard plate 7 includes a base plate 10 located below the lower bracket 3, on which a zigzag pattern 11 / 14 is drawn. The light source 5 emits projection light, which passes through the test sieve 6 and is projected onto the bottom plate 10 .

[0035] When testing the test sieve 6, the test sieve 6 to be tested is installed on the lower bracket 3, and the upper bracket 2...

Embodiment 2

[0049] Such as Figure 1 to Figure 6c As shown, the present embodiment provides a verification method for detecting the test sieve 6, comprising the following steps:

[0050] Assemble the above-mentioned sieve hole deviation checking device, in order to facilitate sliding, the upper bracket 2 and the lower bracket 3 can be properly coated with lubricating oil.

[0051] According to the size of the screen mesh of the test sieve 6 to be tested, the upper bracket 2 is adjusted to be extended to a sufficient length so that the projected light can be irradiated vertically to any sieve hole, and then the upper bracket 2 is fixed.

[0052] Fix the test sieve 6 to be tested on the installation position of the lower bracket 3 and ensure it is level, select any sieve hole to align with the projection light source 5, then fix the extension distance of the lower bracket 3, and adjust the longitudinal position of the lower bracket 3 so that the sieve to be tested The projection of the hol...

Embodiment 3

[0068] Such as Figure 1 to Figure 4 ,as well as Figure 6a , Figure 6b , Figure 6c As shown, the basic size L is selected in this embodiment 0 = 25mm, metal perforated plate test sieve 6 with permissible size deviation of sieve hole w=1.25mm, the shape of the sieve hole is square, and the diameter of the sieve is 400mm. The specific inspection is carried out according to the following steps:

[0069] a. After assembling the equipment, extend the upper bracket 2 to about 300mm and tighten it, turn on the power of the projection light source 5, confirm that the light source 5 is turned on normally, and confirm that the height of the upper bracket 2 is L AC =380mm;

[0070] b. Fix the screen on the lower bracket 3 and tighten it, adjust the level with a level ruler, select the screen hole in the center area of the screen, adjust the extension length of the lower bracket 3, and make the selected screen hole align with the projection light source 5; then adjust The upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com