Portable wing ultrasonic nondestructive flaw detection scanning equipment and mounting method

A non-destructive flaw detection and ultrasonic technology, which is used in material analysis, measurement devices, and instruments using sonic/ultrasonic/infrasonic waves, which can solve the problems of difficult operation, low detection efficiency, and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

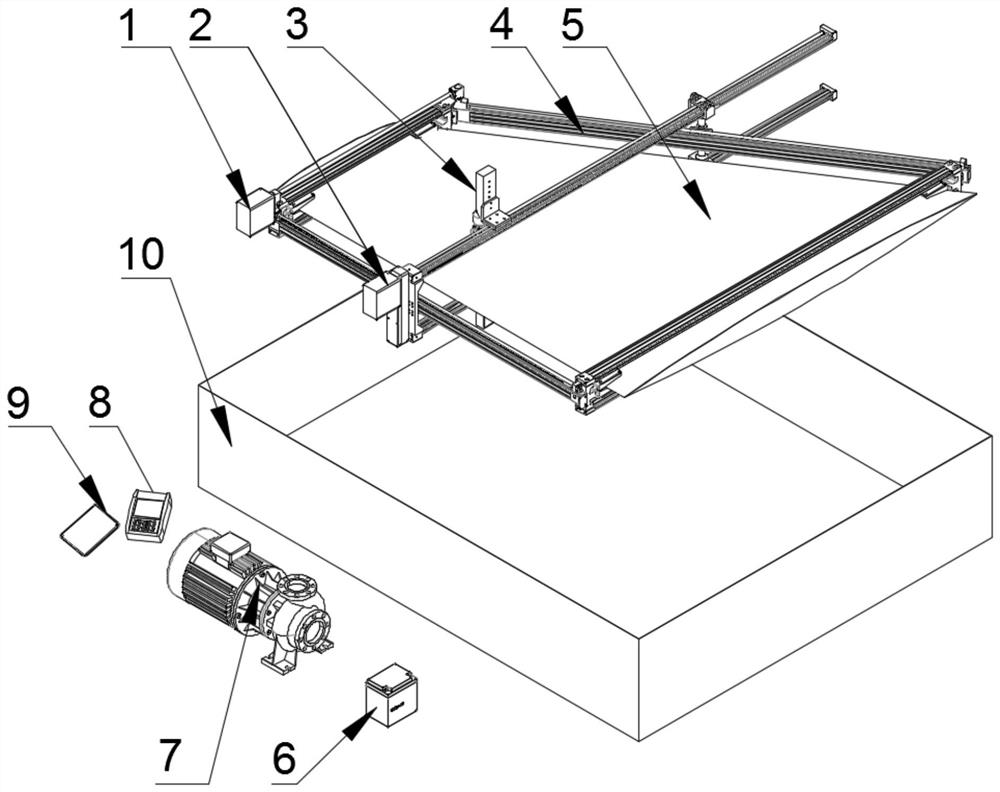

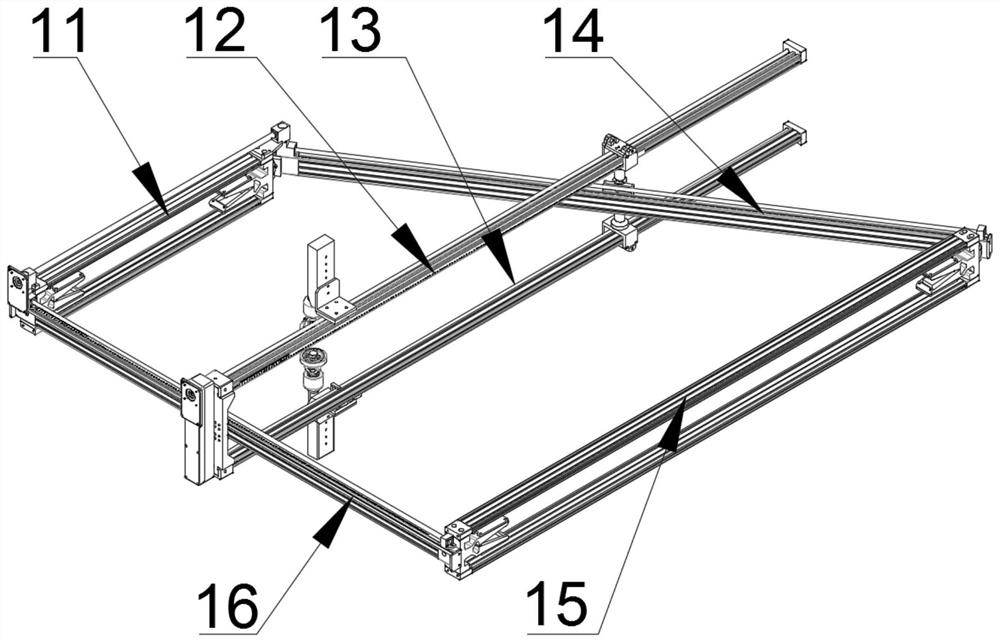

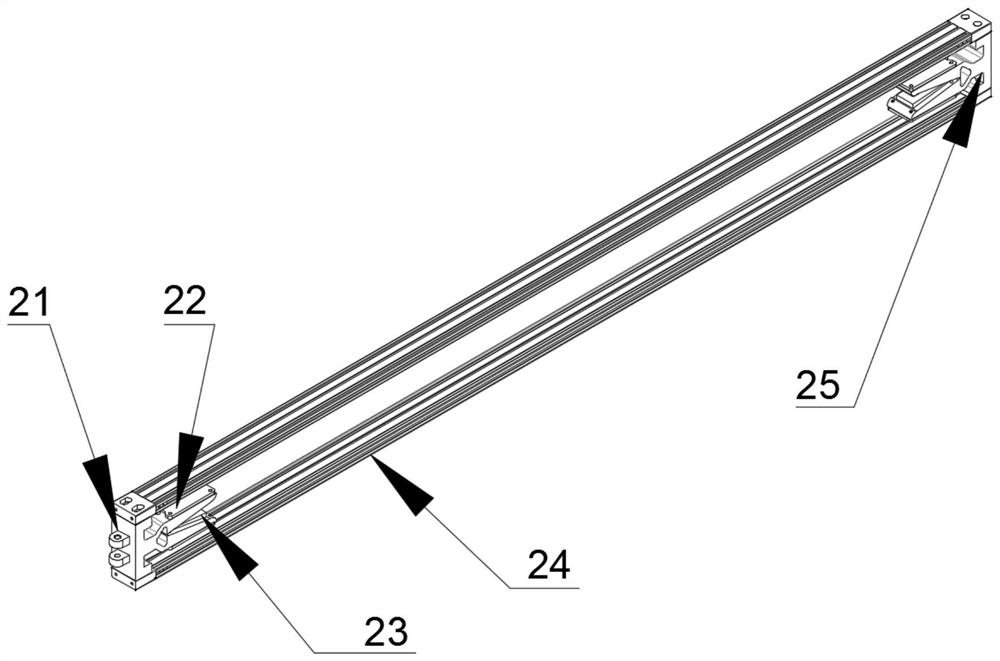

[0060] Embodiment 1, refer to Figure 1-Figure 6 and Figure 8, a portable wing ultrasonic non-destructive testing equipment, including a scanning fixture 4, an end effector 3, an ultrasonic flaw detector 8, a control panel 9, a mobile power supply 6 and a stepping motor, wherein: the scanning fixture 4 includes Short clamping link 11, upward Y-direction rail link 12, downward Y-direction guide rail link 13, X-direction inclined guide rail link 14, long clamping link 15 and X-direction short guide rail link 16, the short clip One end of the holding link 11 and the long clamping link 15 is fixedly provided with a first clamping fixture 21, and the other end of the short clamping link 11 and the long clamping link 15 is fixedly provided with a second clip. One end of the X-direction inclined guide rail connecting rod 14 and the X-direction short guide rail connecting rod 16 is fixedly provided with a first pin ear joint 52, and the X-direction inclined guide rail connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com