Inter-plant weeding and fertilizing machine

A fertilizer applicator and plant-to-plant technology, applied in fertilization devices, soil preparation machines, fertilizer distributors, etc., can solve problems such as difficult data processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

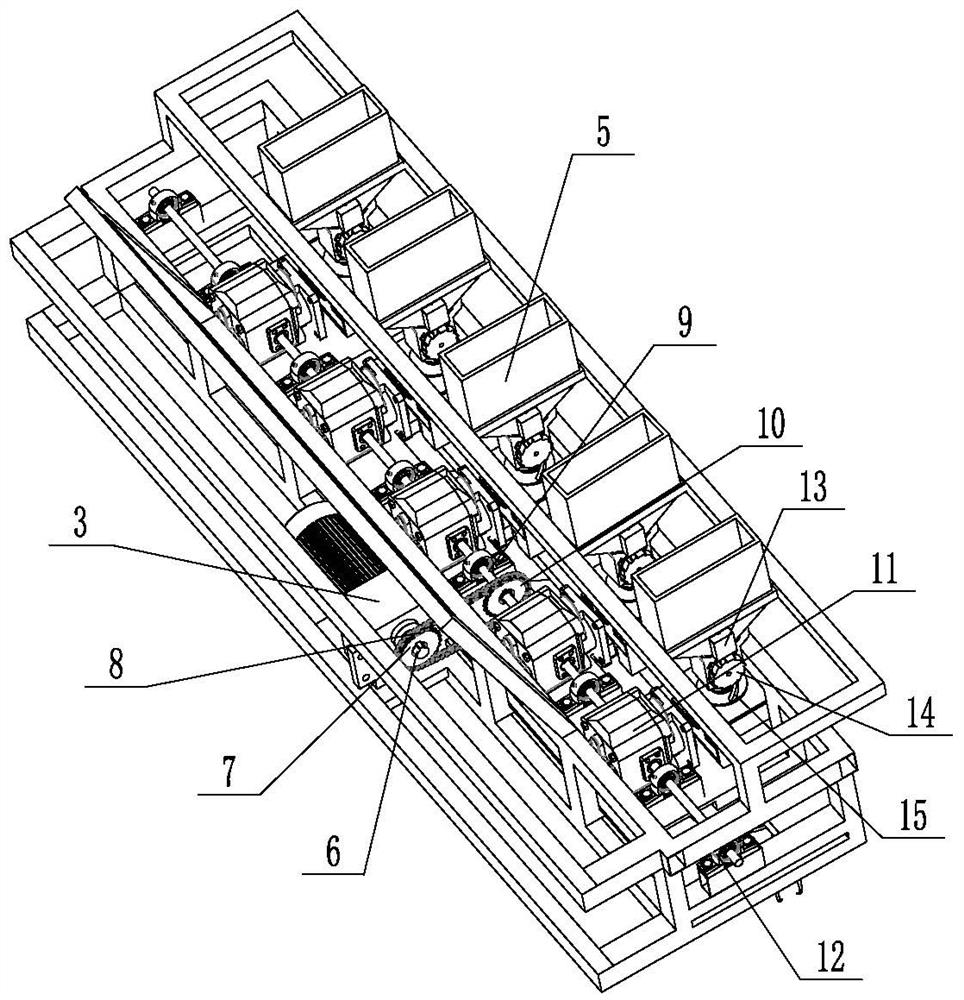

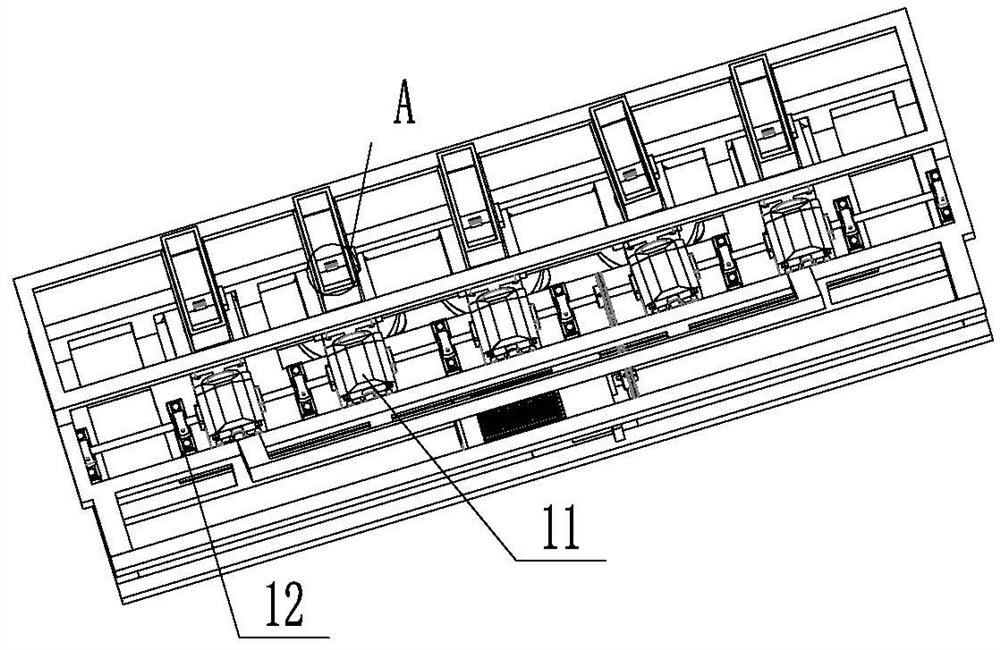

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

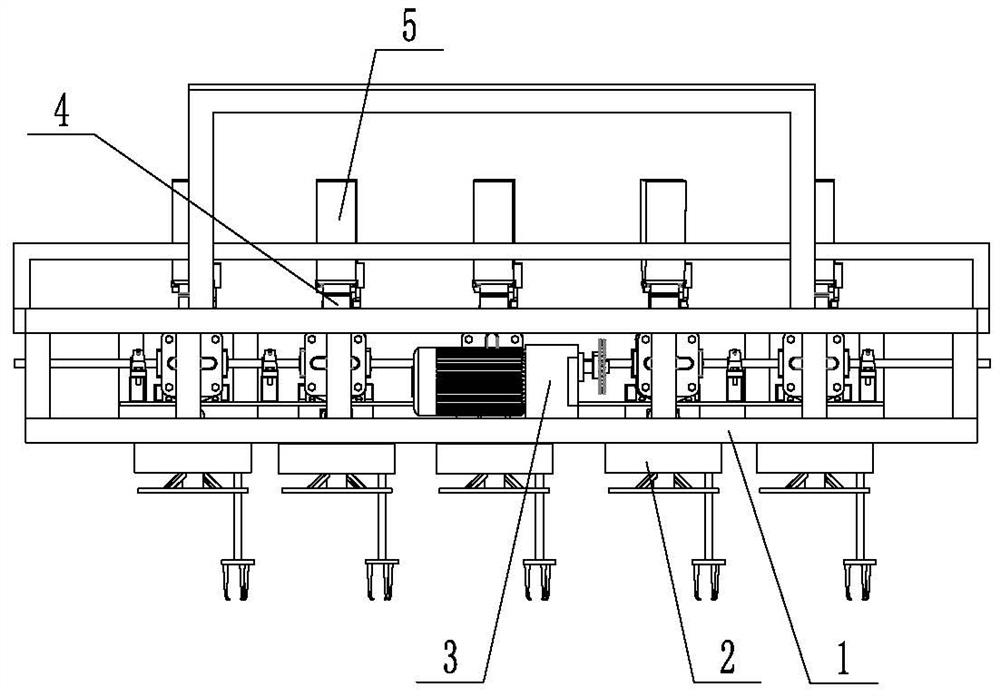

[0029] Such as Figure 1~14 A kind of inter-row weeding and fertilizing machine shown includes a frame 1, and several weeding mechanisms 2 are arranged on the length direction of the frame 1. The weeding mechanism 2 includes a fixed cover 213 and is rotatably connected to the frame 1 and vertically The transmission shaft 206 that is set straightly, the bottom of transmission shaft 206 is connected with turntable 205, and turntable 205 is just sleeved on the bottom of transmission shaft 206, and the lower side of transmission shaft 206 is fixedly connected with fixed plate 215, and the center of fixed plate 215 is provided with convenient and transmission shaft. 206 to connect the fixed holes 221, the fixed plate 215 outside the transmission shaft 206 is arranged with several connecting holes 220, the fixed plate 215 is fixedly connected with the turntable 205, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com