Dedusting device for environment-friendly machinery

A technology of dust removal device and machinery, applied in the direction of using liquid separating agent, filtration loop, filtration separation, etc., can solve the problems of inability to sense garbage and impurities, inconvenient maintenance, and the flying of particulate matter.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

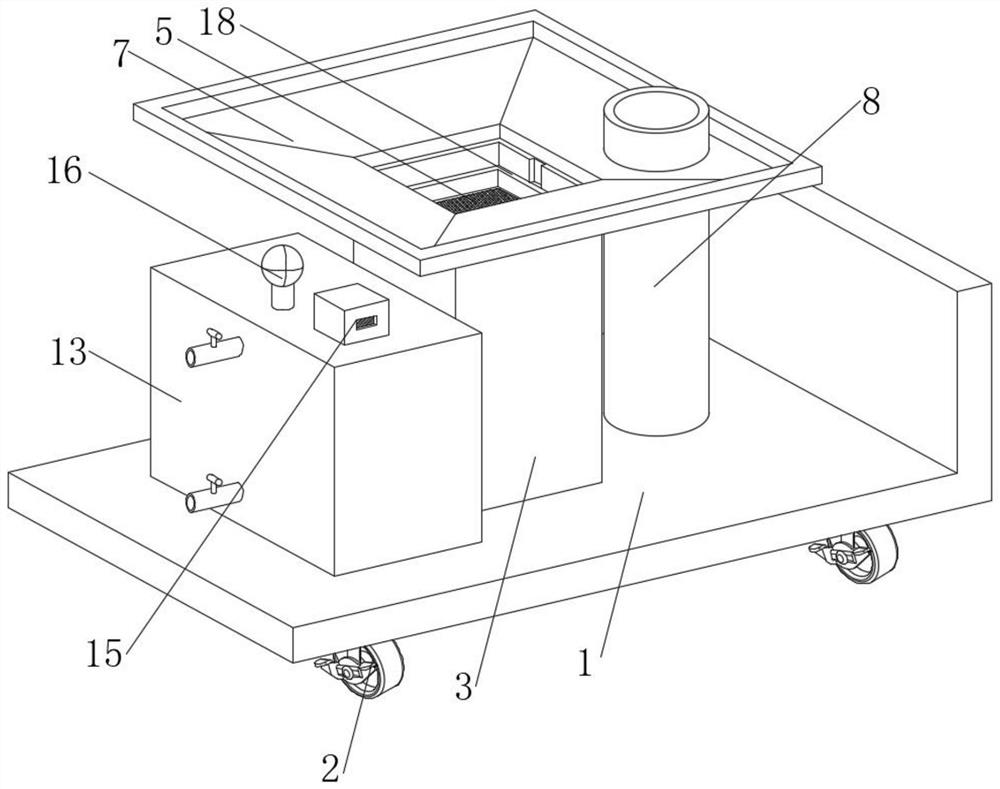

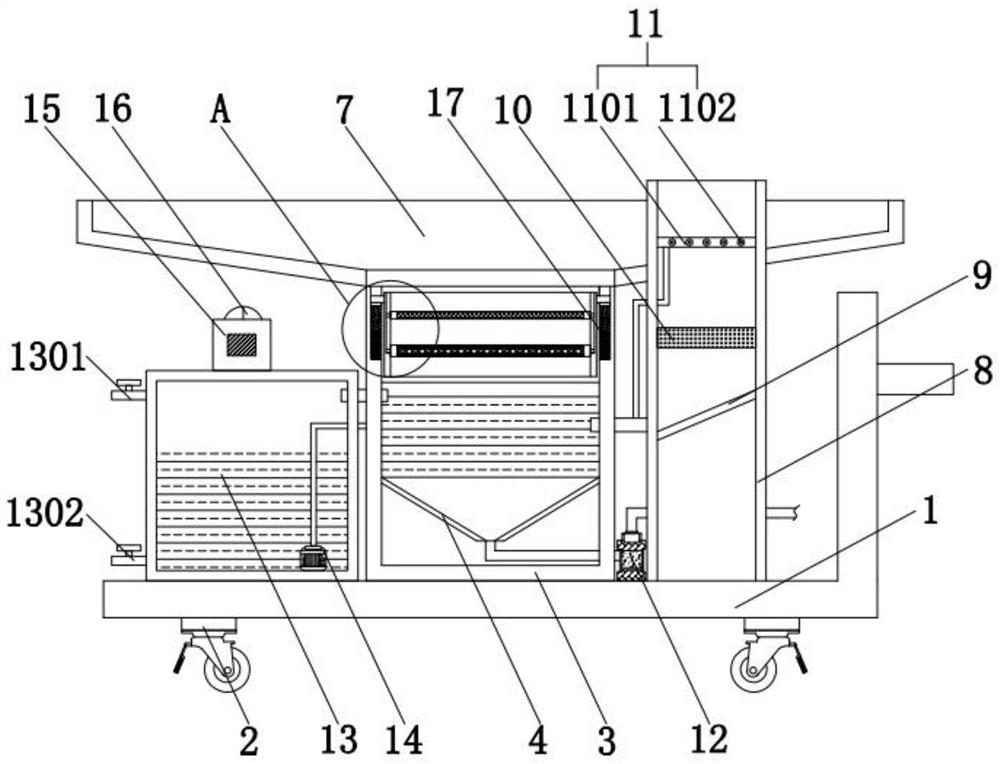

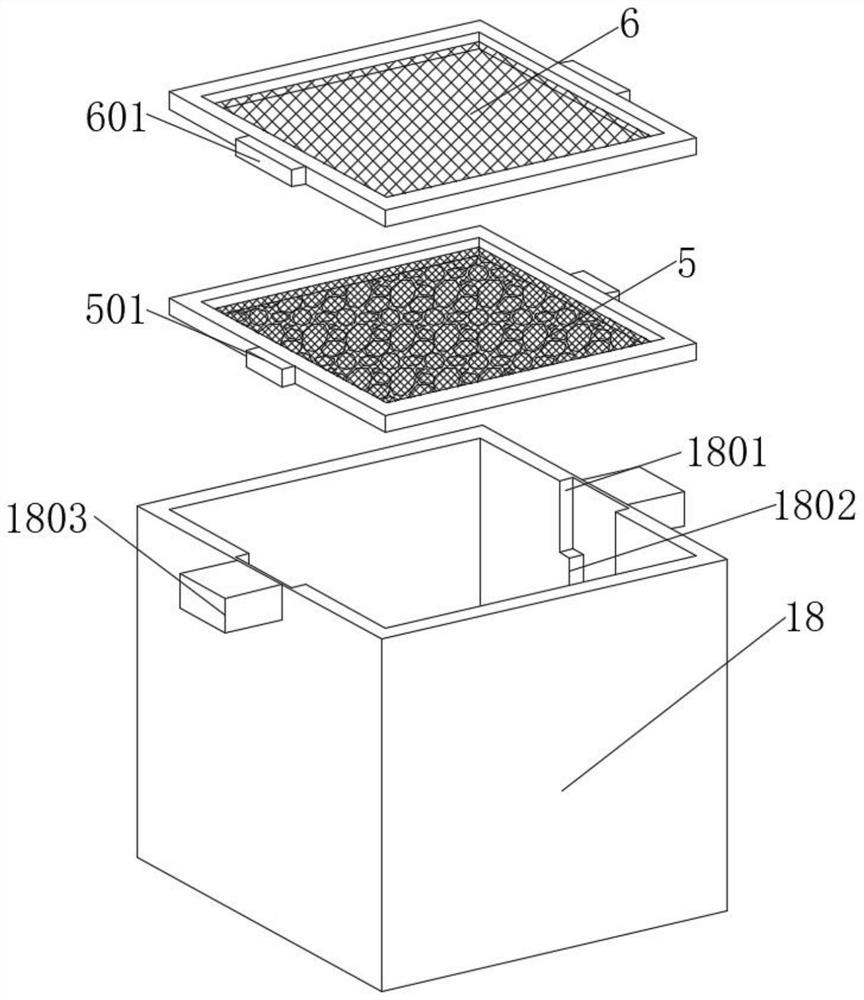

[0030] see Figure 1-4 , a dust removal device for environmental protection machinery, comprising a bottom plate 1, the four corners of the bottom of the bottom plate 1 are fixedly connected with universal wheels 2, the top of the bottom plate 1 is fixedly connected with a sedimentation tank 3, and the top of the sedimentation tank 3 is fixedly connected with a water collection frame 7 , the inner wall of the sedimentation tank 3 is fixedly connected with a funnel 4, the top of the bottom plate 1 is fixedly connected with a dredge pump 12, the left end of the dredge pump 12 is connected with a connecting pipe, and the left end of the connecting pipe runs through the sedimentation tank 3 and is connected with the bottom of the funnel 4 The inner wall of the settling box 3 is clamped with a square frame 18, the inner wall of the square frame 18 is clamped with a filter device 5, the inner wall of the square frame 18 is clamped with a filter plate 6 above the filter device 5, and ...

Embodiment 2

[0039] like Figure 5 to Figure 6 As shown, in this example,

[0040] The top of the circular tube 8 is provided with a charge loading device 19, and the charge loading device 19 includes a cathode discharge plate 19-1 and an anode discharge plate 19-2 symmetrically arranged on the inner wall of the circular tube 8. The discharge plate 19-1 is connected to a high-voltage power supply, and the anode discharge plate 19-2 is grounded,

[0041] The upper surface of the water collection frame 7 is provided with several rows of uniformly distributed water collection arrays 20 extending toward the settling tank 3. The water collection arrays 20 include a number of vertically arranged inverted V-shaped water collection plates. The water collecting plate is made of metal, and the adjacent water collecting arrays 20 are respectively connected to the positive pole and the negative pole of the power supply,

[0042] The lower bottom surface of the water collection frame 7 is provided wi...

Embodiment 3

[0051] like Figure 7 As shown, in this example,

[0052] Openings 302 are provided on the front and rear sides of the upper part of the sedimentation tank 3, and the opening 302 on the front side is provided with a flip cover 303, and the bottom plate 1 on the rear side of the sedimentation tank 3 is provided with a replacement device 22. The inner walls of the left and right sides of the settling box 3 are provided with a second chute 304 horizontally, the left and right side walls of the middle part of the settling box 3 are provided with lifting devices 23, the square frame 18 is provided with a handle 1804 on the front side, and the flip cover 303 inside is provided with a number of limit blocks 305, the replacement device 22 includes a box 22-1, the bottom of the box 22-1 is provided with an electronically controlled lifter 22-2, and the electronically controlled lifter 22 The top of -2 is provided with a bearing plate 22-3, and the electric control push rod 22-4 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com