Mixing and preparation equipment for modified starch glue

A technology of modified starch and glue, applied in mixers, mixers with rotary stirring devices, mixer accessories, etc., can solve the problems that affect the quality of modified starch glue, consume a lot of physical effort, and stir unevenly, and achieve perfect modified starch glue. , The effect of reducing physical strength and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

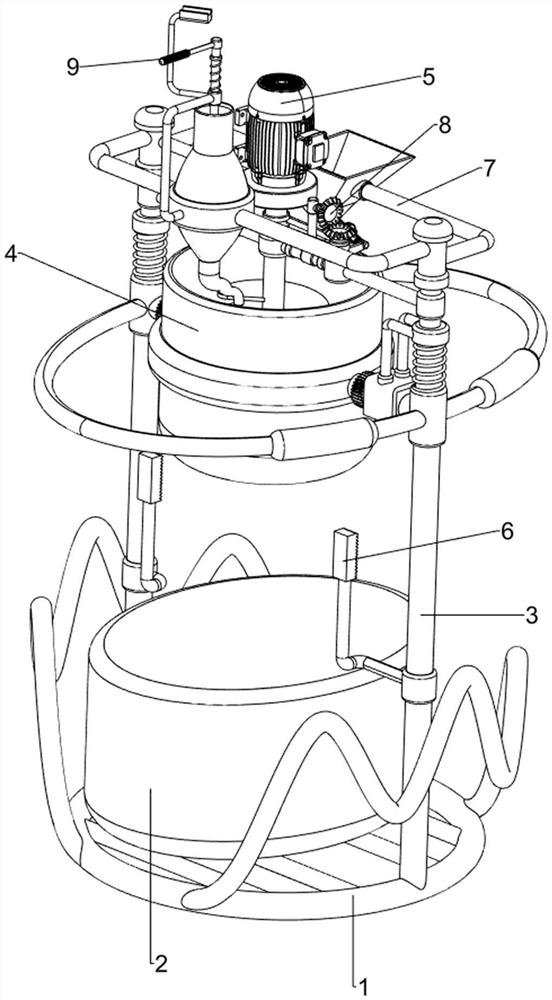

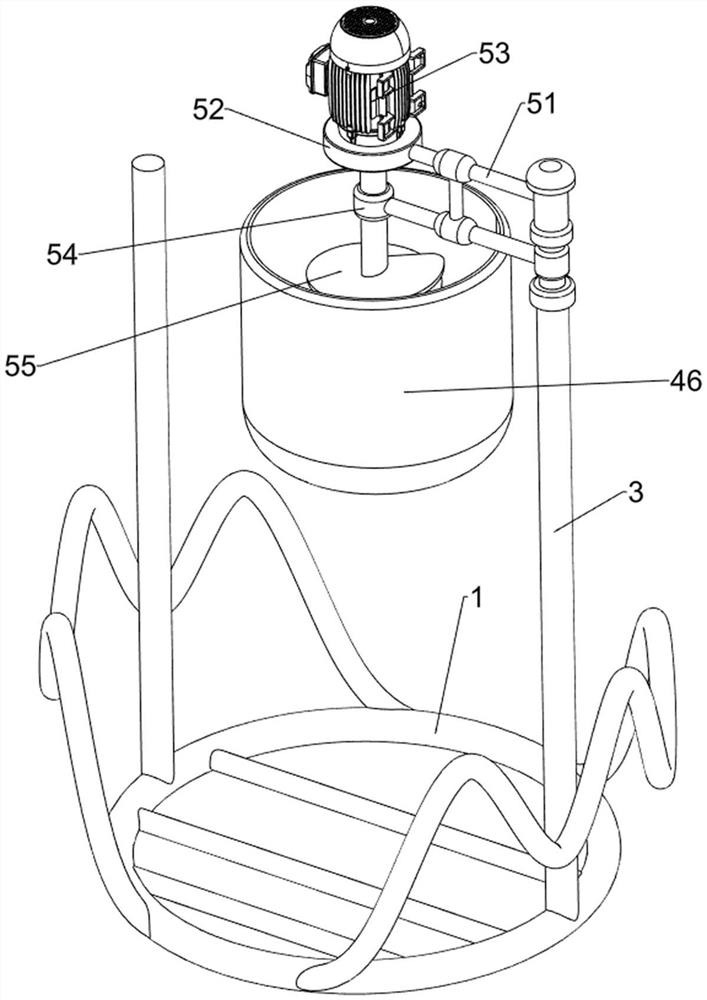

[0027] A kind of mixed preparation equipment for modified starch glue, such as Figure 1-3 As shown, it includes a base 1, a collection frame 2, a first slide bar 3, a discharge mechanism 4 and a stirring mechanism 5, a collection frame 2 is placed on the base 1, and the first slide bar 3 is welded on the left and right sides of the base 1 , A discharge mechanism 4 is provided between the first slide bars 3, and a stirring mechanism 5 is provided on the first slide bar 3 on the left side.

[0028] When it is necessary to mix and prepare modified starch glue, put the modified starch and water into the discharge mechanism 4, then start the stirring mechanism 5, and the stirring mechanism 5 will stir the modified starch and water, and then make the modified starch glue. After the starch glue is mixed and prepared, close the stirring mechanism 5, and then control the discharge mechanism 4 to pour the modified starch glue into the collection frame 2.

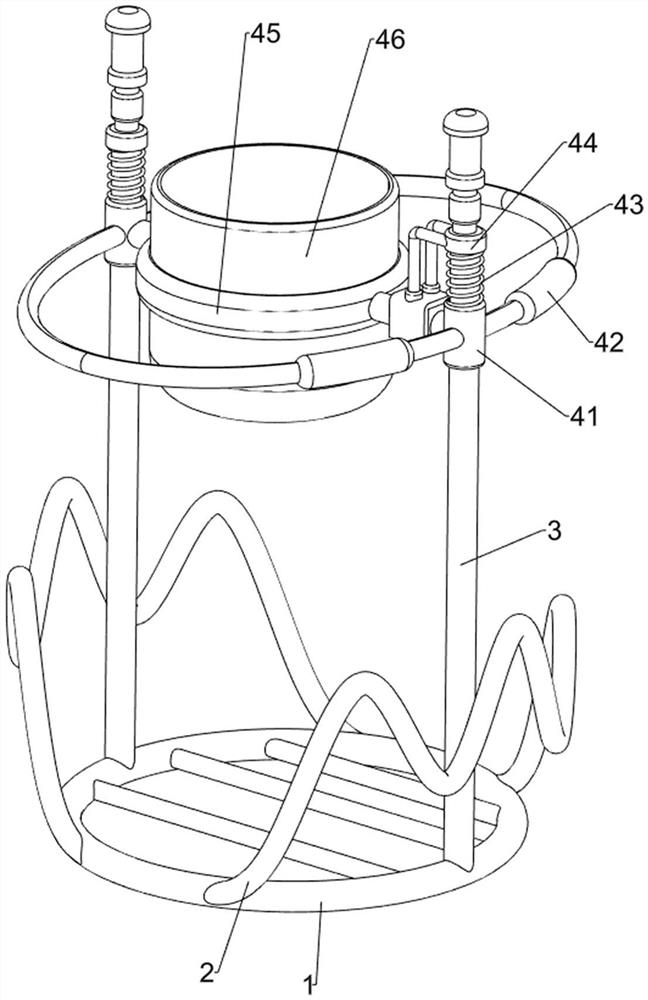

[0029] The discharge mechani...

Embodiment 2

[0034] On the basis of Example 1, such as figure 1 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, it also includes a rotation mechanism 6, the rotation mechanism 6 includes a first support rod 61, a rack 62 and a first ordinary gear 63, and the middle part of the first slide bar 3 is welded with a first support rod 61, and the first support rod The upper inner side upper part of 61 is connected with rack 62, and the left and right sides of rotating block 45 are all key-connected with the first common gear 63, and the first common gear 63 meshes with rack 62.

[0035] When it is necessary to take out the modified starch glue that has been mixed and prepared, the first handle 42 is controlled to move downward, so that the rotating block 45 moves downward, the first spring 43 is stretched, and then the first ordinary gears 63 on both sides are driven downward Move, when the first common gear 63 is meshed with the rack 62, the first common gear 63 will be rotated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com