Multi-connected pneumatic numerical control device for forming cross-shaped through hole kidney-shaped grooves of bolts

A technology of cross hole and numerical control device, applied in positioning device, clamping device, clamping, etc., can solve the problems of low processing efficiency and product pass rate, achieve high processing efficiency, improve processing efficiency, and ensure quality problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

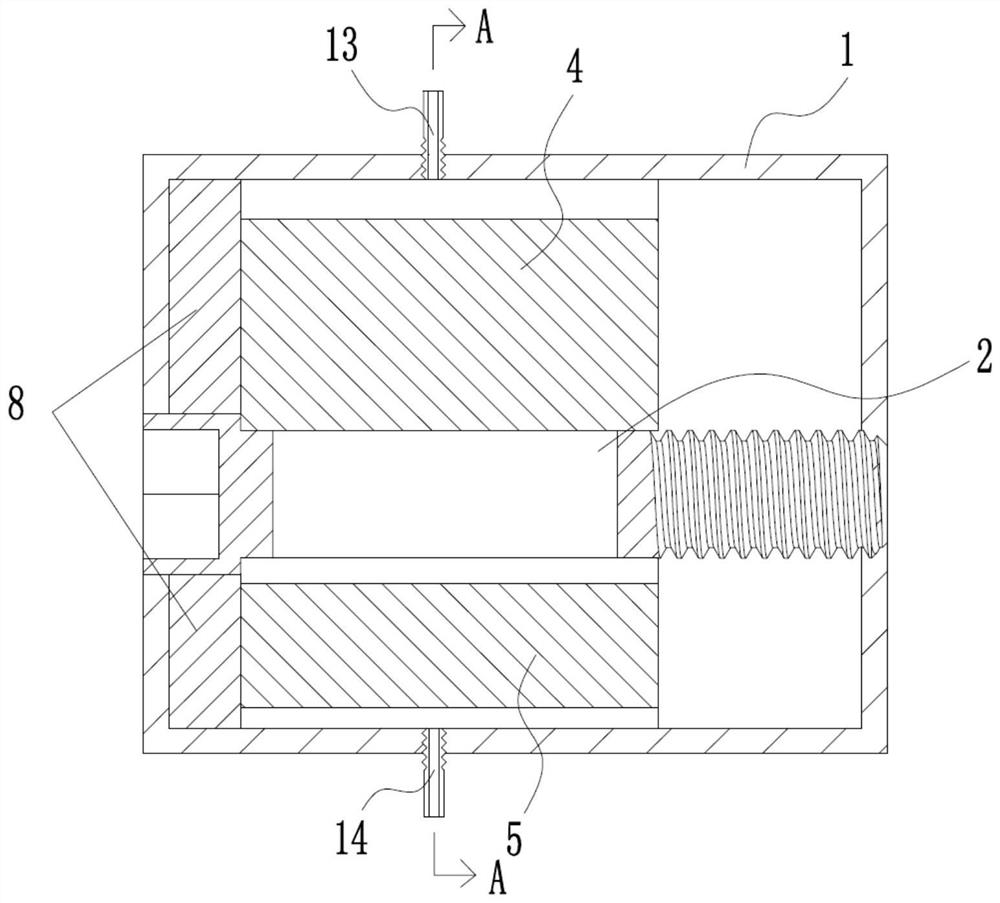

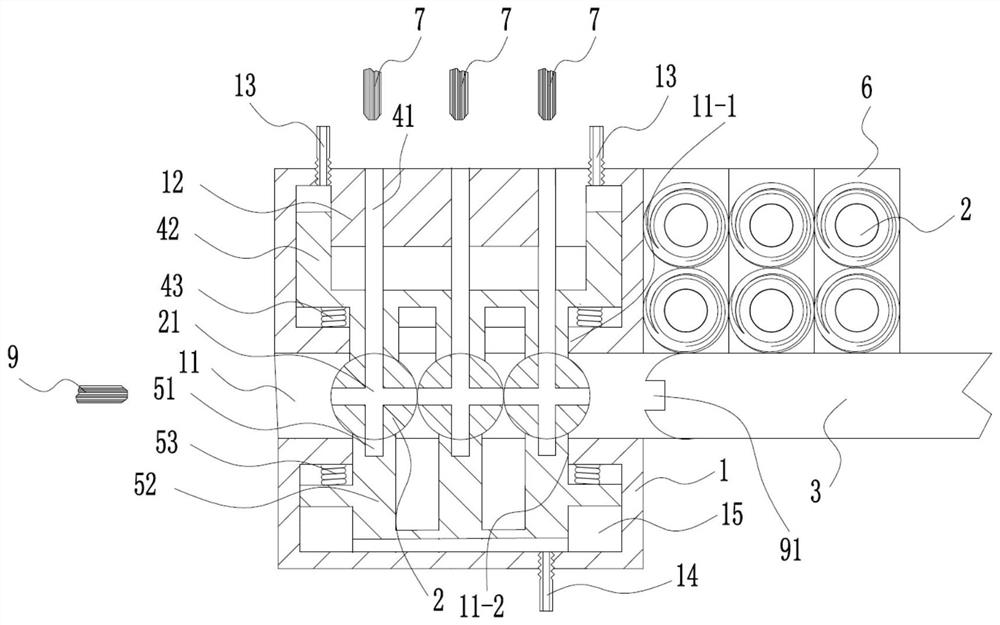

[0015] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 , 2 As shown, the present invention includes an airtight casing 1, and the center of the casing 1 is provided with a channel 11 for the radial sliding of the bolt 2, and a pneumatic ejector rod 3 is slidably connected in the channel 11, and the pneumatic ejector rod 3 can slide along the channel. 11 The push bolt 2 has a first milling cutter 9 distributed opposite to the pneumatic ejector rod 3, and a first return groove 91 corresponding to the first milling cutter 9 is provided on the end surface of the first milling cutter 9, so that the first milling cutter 9 A milling cutter 9 can mill out a through hole waist groove 21 along the channel 11 on the bolt body; the upper part of the casing 1 is provided with an upper mold assembly 4, and the lower part of the casing 1 is provided with a lower mold assembly 5, and the upper mold assembly Component 4 and lower mold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com