Polishing machine for iron stair strut of industrial style furniture

A technology of polishing mechanism and pillar, applied in the direction of manufacturing tools, grinding workpiece supports, grinding/polishing equipment, etc., can solve the problems of single function, time-consuming and laborious, low efficiency, etc., and achieve the effect of easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

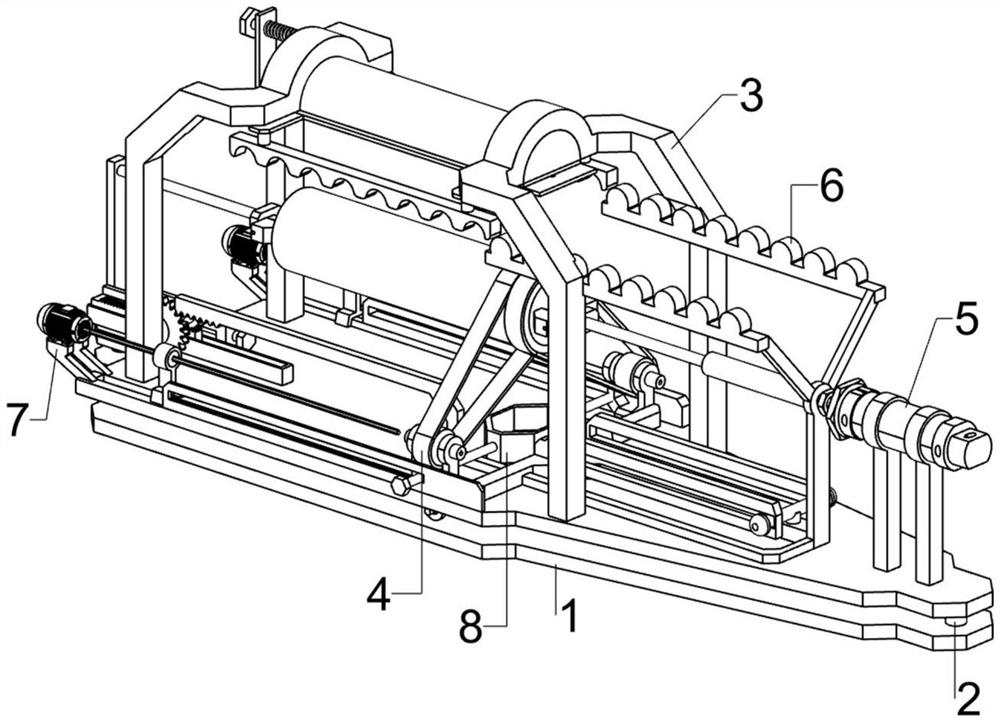

[0070] An industrial style furniture iron staircase pillar polishing machine, such as Figure 1-3 As shown, it includes a bottom plate 1, a pillar 2, a mounting assembly 3 and a polishing mechanism 4. The top of the bottom plate 1 is uniformly provided with a pillar 2, and the top of the pillars 2 is connected with a mounting assembly 3, and a polishing mechanism 4 is provided on the mounting assembly 3.

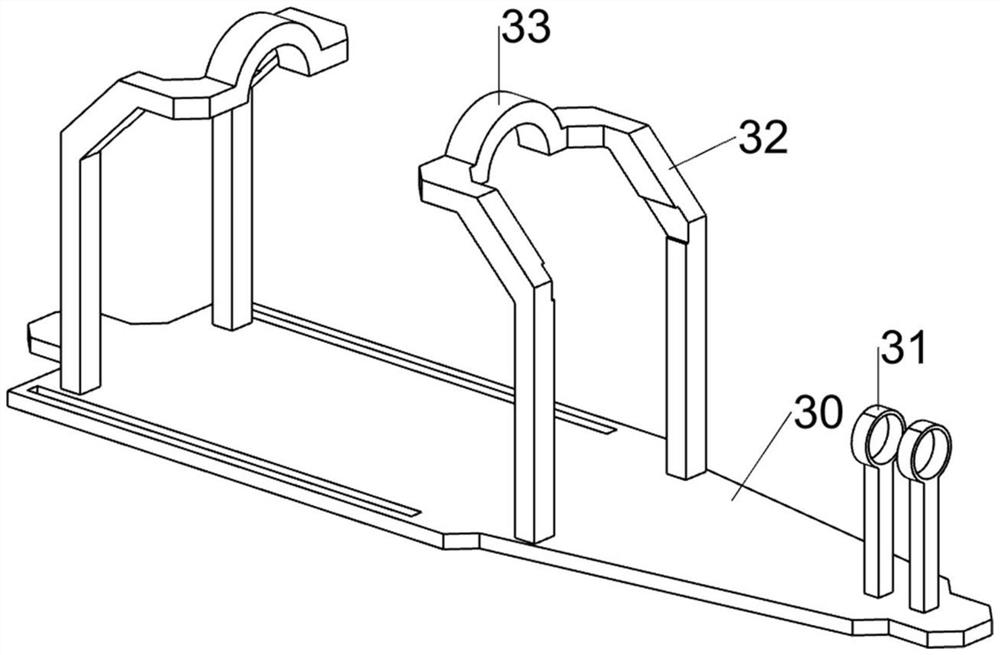

[0071] The mounting assembly 3 includes a mounting plate 30, a first mounting seat 31, a support rod 32 and a fixed ring 33, the mounting plate 30 is connected between the tops of the pillars 2, and the first mounting seat 31 is evenly arranged on the right side of the mounting plate 30 top, and the installation Two supporting rods 32 are arranged on the left and right sides of the top of the board 30 , and a fixing ring 33 is arranged between the two supporting rods 32 on the same side.

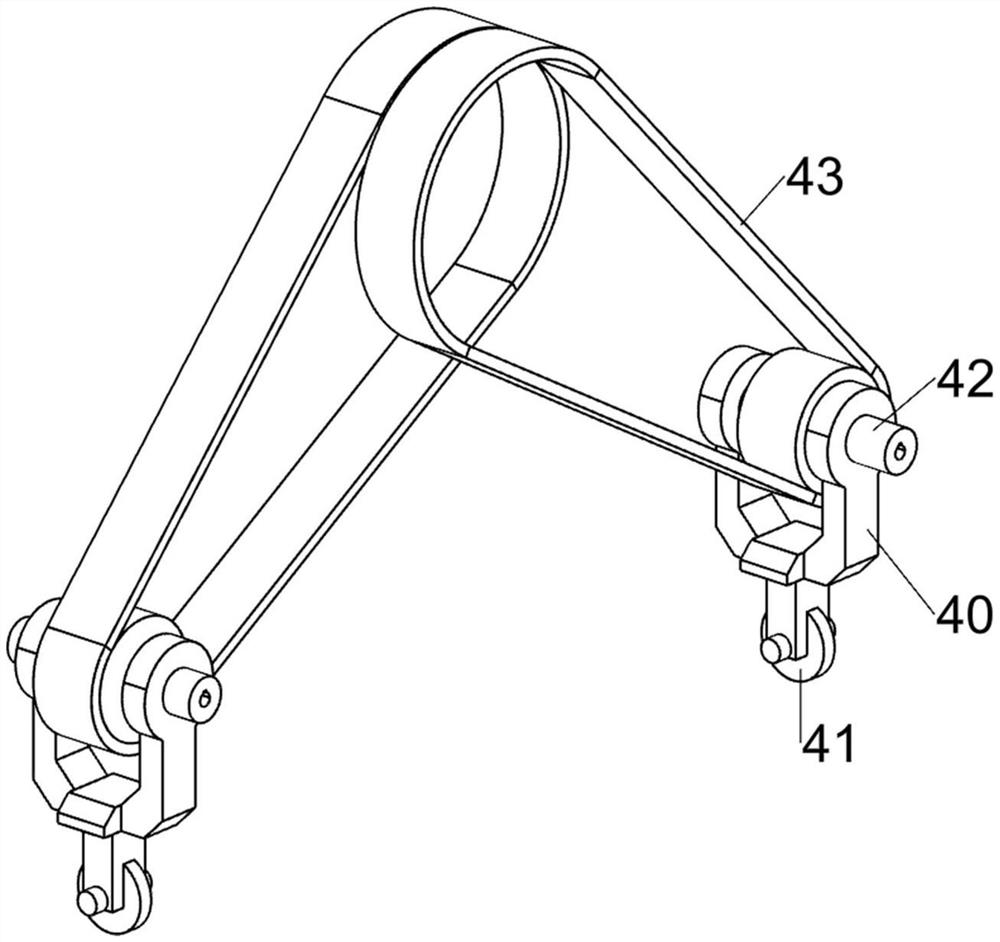

[0072]The polishing mechanism 4 includes a special-shaped block 40, a runner 41, a fir...

Embodiment 2

[0075] On the basis of Example 1, such as Figure 4-9 As shown, a clamping mechanism 5 is also included, and the clamping mechanism 5 includes a cylinder 50, a sliding plate 51, a hollow cylinder 52, a short rod 53, a first rack 54, a first bearing seat 55, a second rotating shaft 56, a One gear 57, the first slide rail 58, the moving plate 59, the fixed block 510, the wedge block 511, the first spring 512 and the second spring 513, are connected with the cylinder 50 between the first mount 31, and the left side of the cylinder 50 is provided with Sliding plate 51, the left side of sliding plate 51 is provided with hollow cylinder 52, and the hollow cylinder 52 is slidably connected with short rod 53, and the second spring 513 is connected between the right side of short rod 53 and the inner wall of hollow cylinder 52, and the bottom of sliding plate 51 The first rack 54 is provided, the left side of the mounting plate 30 is provided with a first slide rail 58, the first slide...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap