Machining die for heat-conducting silica gel pad and application method of machining die

A technology of thermally conductive silicone and processing molds, applied in metal processing and other directions, can solve the problems of poor deformation, difficult production, and large force on the entire surface of the thermally conductive silicone pad, achieving simple manufacturing, solving the limitations of processing shapes, and improving processing. range effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

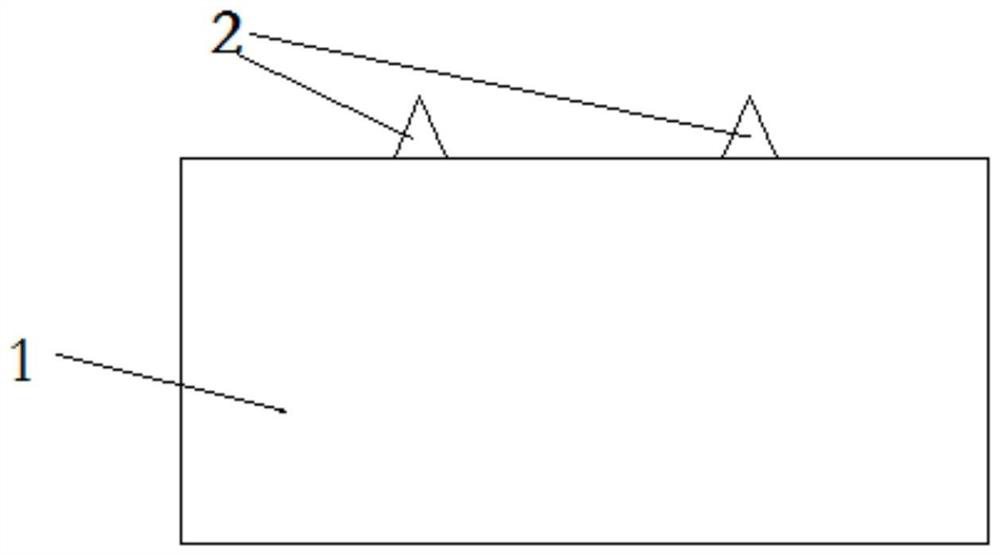

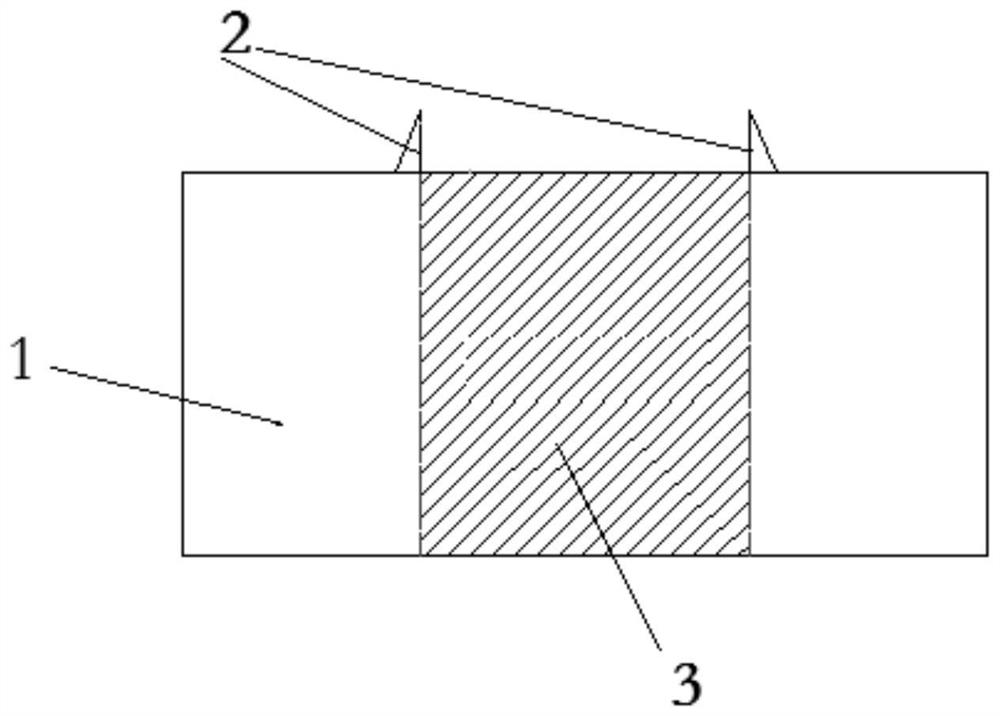

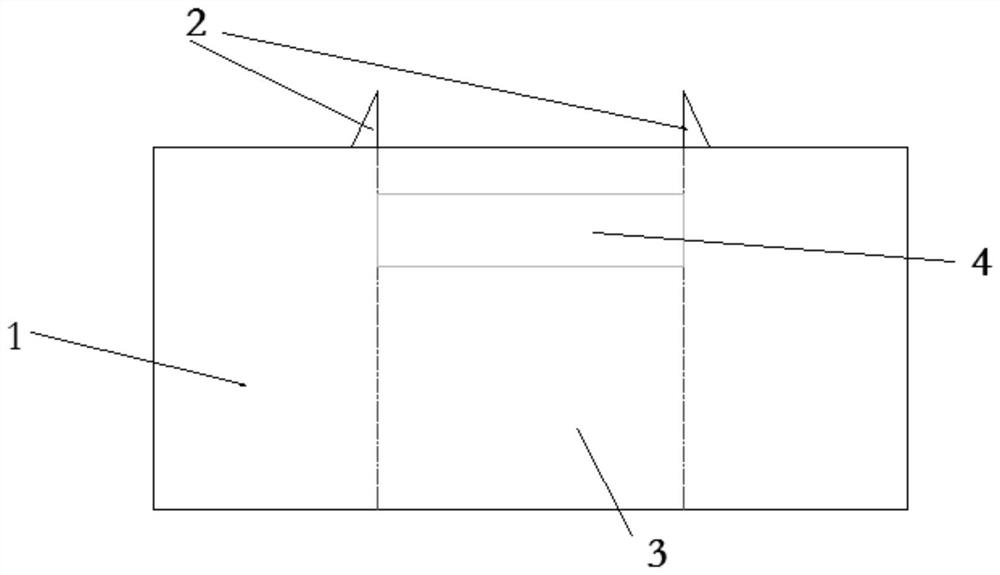

[0038] A processing mold for a thermally conductive silicone pad, such as figure 2 As shown, the finished heat-conducting silicone pad for processing a circular shape includes a mold bottom plate 1, a triangular blade 2 on the surface of the mold bottom plate 1, a circular through-hole 3 on the mold bottom plate 1, and sliding installation The finished product ejector rod 5 in the through hole 3; the blade edge 2 is arranged along the periphery of the through hole 3, including the first blade surface and the second blade surface, and the angle between the two is less than 30°, and the peripheral circle of the through hole 3 Matches the roundness formed by the apex of the blade 2. The hole wall of the through hole 3 is perpendicular to the surface of the mold bottom plate 1, the first blade surface is arranged along the extension direction of the hole wall of the through hole 3, and the second blade surface forms an angle with the surface of the mold bottom plate 1, so the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com