Rubber production equipment

A technology for production equipment and rubber, which is applied in the direction of cleaning hollow objects, chemical instruments and methods, cleaning methods and utensils, etc., can solve problems such as untimely cleaning, waste of resources, and difficulty in cleaning, so as to facilitate subsequent use and reduce power Use, spray fast and even effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

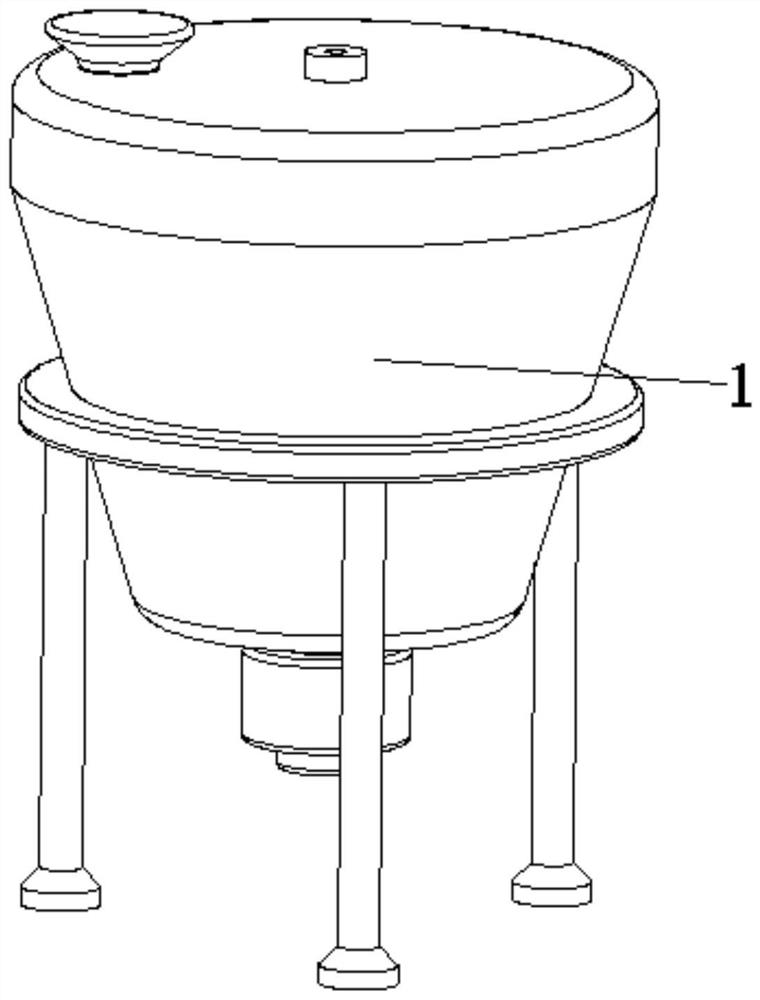

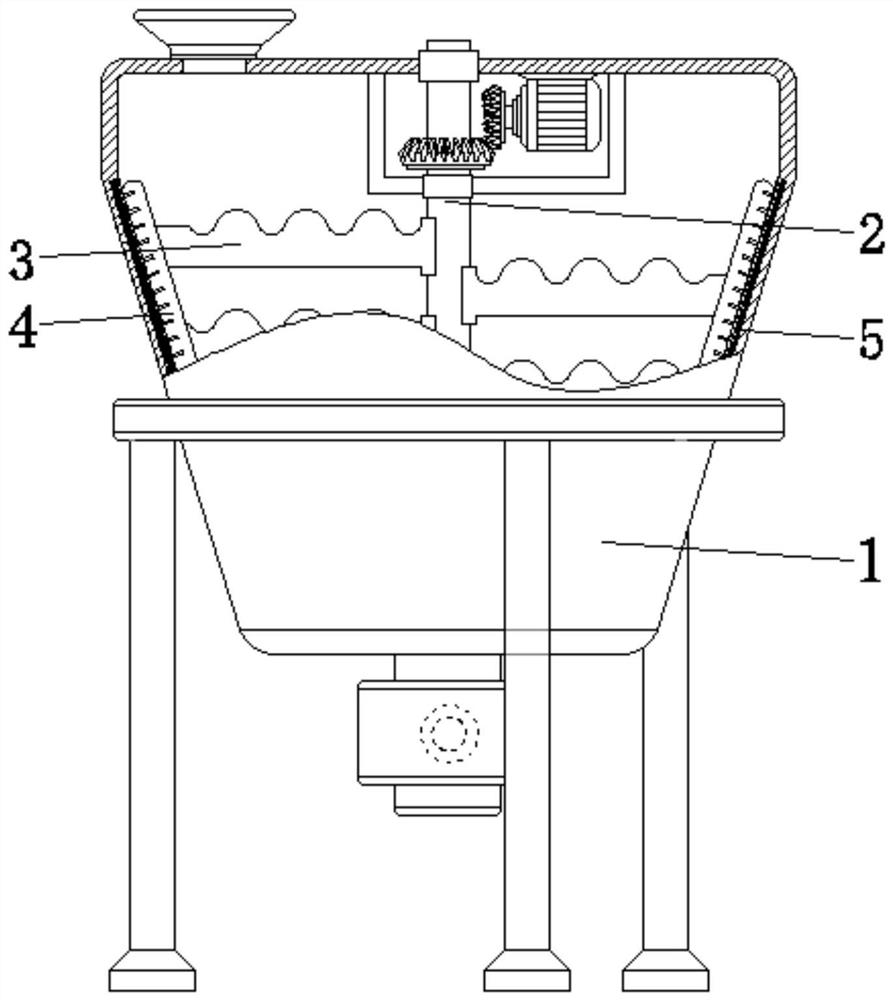

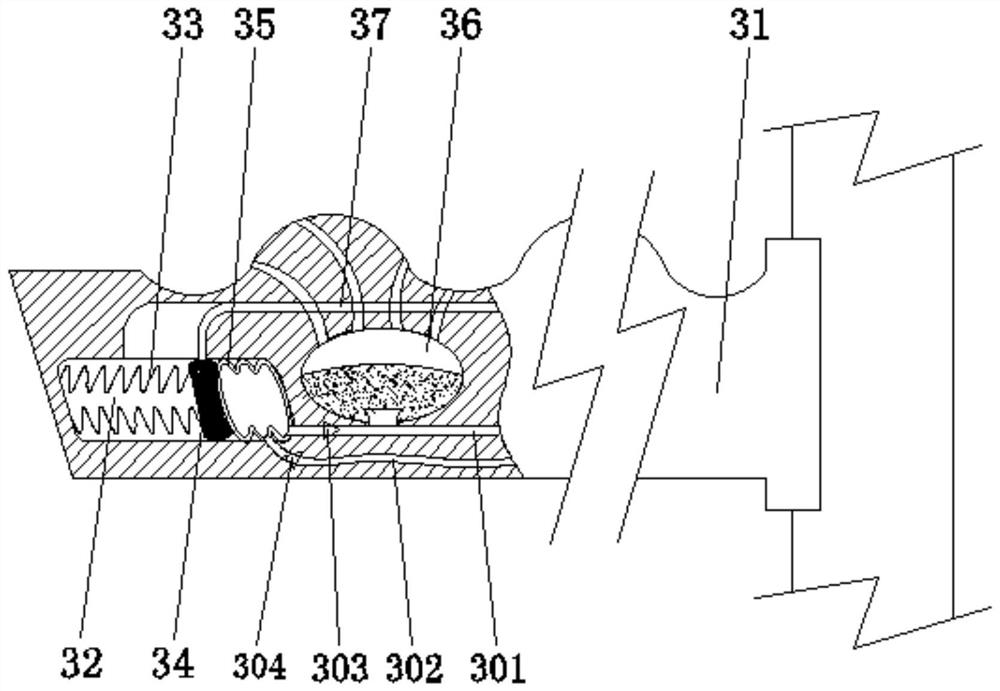

[0034] see Figure 1-8, the present invention provides a technical solution: a rubber production equipment, including a body 1, the body 1 is provided with a rotating shaft 2, a stirring device 3, a wall scraping device 4, and a magnetic strip 5, and the rotating shaft 2 is rotatably connected to the central position of the inner wall of the body 1, The stirring device 3 is fixed on the surface of the shaft 2, the wall scraping device 4 is fixed on the end of the stirring device 3 and is located at the inner wall of the body 1, the magnetic strip 5 is arranged inside the body 1, and the stirring device 3 is provided with a stirrer 31, an inner cavity 32. Return spring 33, magnetic block 34, elastic air bag 35, storage chamber 36, spray device 37, the inner cavity 32 is set inside the stirrer 31 and is located at the end, and the return spring 33 is fixed on the inner cavity 32 One side of the inner wall, the magnetic block 34 is fixed on the top of the return spring 33, the el...

Embodiment example 2

[0038] The wall scraping device 4 is provided with a scraper device 41, a rectangular notch 42, and a cutter 43. The rectangular notch 42 is set on one side of the surface of the scraper device 41, and the cutter 43 is fixed on the surface of the scraper device 41 and is positioned at the side of the rectangular notch 42. Position, through its own rotation, the viscous material can be scraped off smoothly, saving time and effort, and the rectangular notch 42 reduces the force-bearing area during scraping, making the resistance smaller. At the same time, during the scraping process, the cutter 43 Segment the viscous, further destroy the adhesion between the viscous, further reduce the resistance, and facilitate subsequent scraping.

[0039] The scraper device 41 is provided with a scraper body 411, a first arc-shaped plate 412, a second arc-shaped plate 413, an arc-shaped surface 414, and a row of holes 415. The first arc-shaped plate 412 and the second arc-shaped plate 413 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com