Motorcycle brake assembly

A motorcycle and assembly technology, applied in the field of motorcycle brake assembly, can solve the problems of high adjustment cost, unadjustable distance between brake handle and grip, cumbersome adjustment operation, etc., and achieves increased operating comfort and less material. , the effect of stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

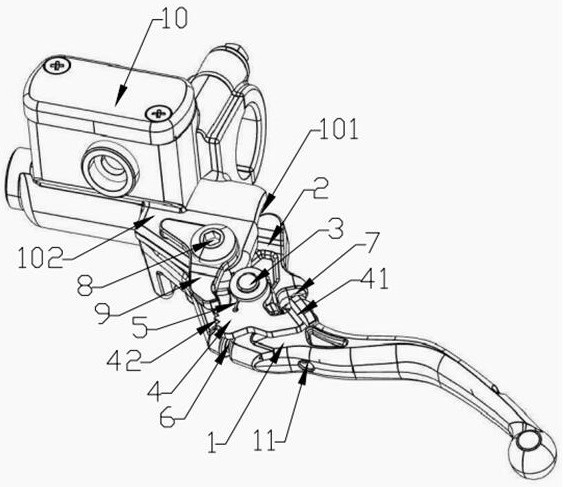

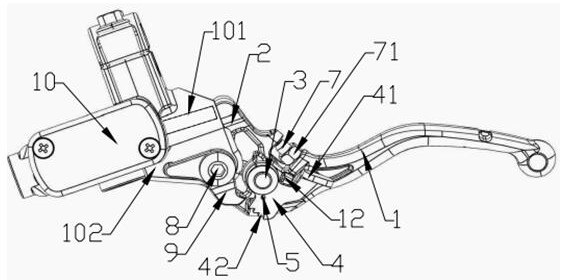

[0019] Such as figure 1 , figure 2 As shown, the motorcycle brake assembly provided by this embodiment includes a brake handle 1 and a hydraulic brake pump 10 installed on the handle of the motorcycle, and a piston rod 101 is arranged in the hydraulic brake pump 10; The brake handle 1 and the hydraulic brake pump 10 are connected together through a handle connecting seat 2, and the brake handle 1 and the handle connecting seat 2 are connected through the brake handle 1 and the handle through a rotating shaft 3 The seat 2 is then rotatably connected with the handle connecting seat 2, and the hydraulic brake pump 10 and the handle connecting seat 2 are rotatably connected through an installation shaft 8; On the same side as the piston push rod), the brake handle 1 is provided with an adjustment plunger 7 whose end is against the handle connection seat 2, and the adjustment plunger 7 can slide and position in the brake handle 1; in the brake handle A parking brake paddle 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com