Nitrogen cabin for nitrogen-filled packaging of tea

A technology of nitrogen-filled packaging and nitrogen gas, which is applied in the field of nitrogen gas tanks, can solve the problems of easy leakage of nitrogen gas, easy contamination of the tank body, and unstable nitrogen filling amount, and achieve the goals of ensuring uniformity, simple structure, and reducing broken rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

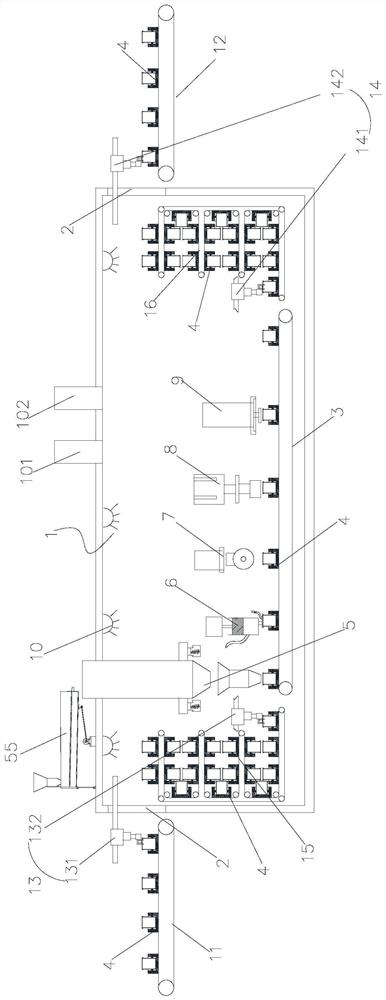

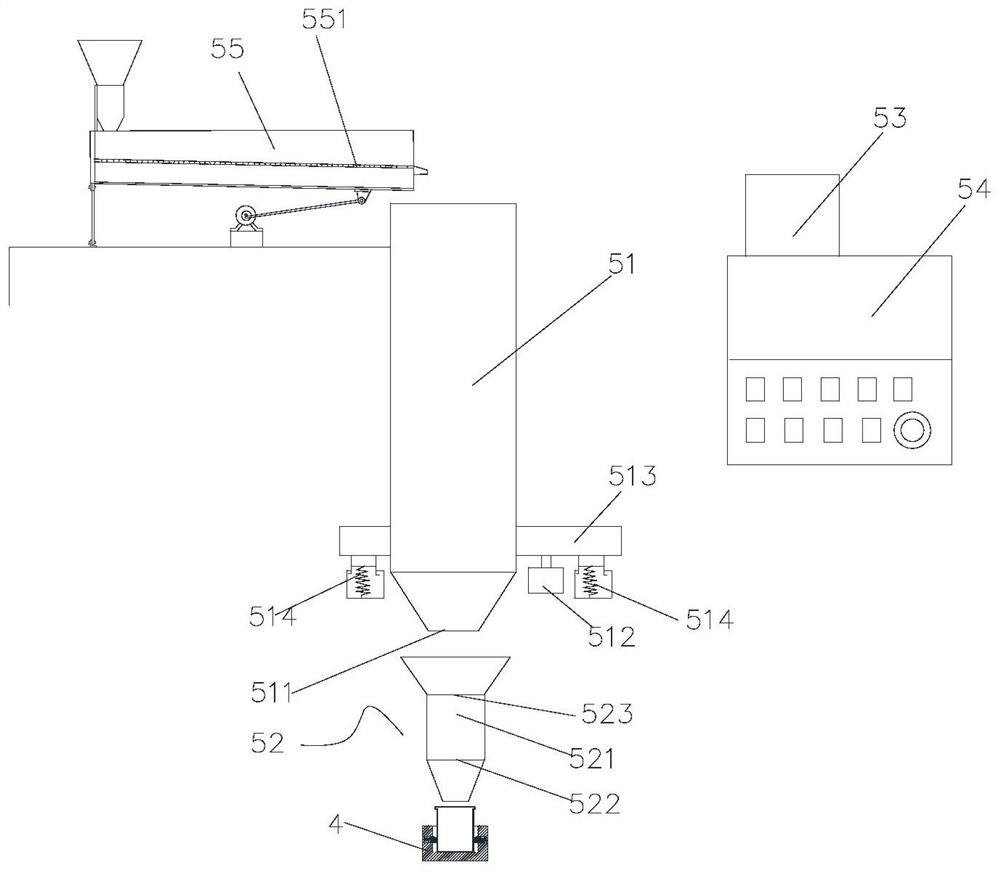

[0018] Examples such as Figures 1 to 4 As shown, a nitrogen chamber for nitrogen-filled packaging of tea is used for canning and nitrogen-filled sealing of tea. The nitrogen chamber includes a nitrogen-filled chamber 1, and the nitrogen-filled chamber 1 is a sealed chamber made of 304 stainless steel. . The nitrogen-filled cabin body 1 is 4.2 meters long, 2.2 meters wide and 3.2 meters high. The two ends of the nitrogen-filled cabin body 1 are provided with hatches 2 that can be opened and closed automatically. The hatches 2 are automatically opened when feeding and discharging materials, and are fully closed during nitrogen-filled packaging. On the nitrogen-filled cabin 1 , an air extraction pipe 101 is also provided for extracting the air in the nitrogen-filled cabin 1 , and a nitrogen gas inlet pipe 102 is also provided for filling nitrogen into the nitrogen-filled cabin 1 . In the nitrogen-filled cabin 1, a conveyor belt 3 is provided, on which a group of tea can bases ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com