Cloth rolling device with centering structure for textile and using method thereof

A utensil, cloth rolling technology, applied in textile and papermaking, strip winding, transportation and packaging, etc., can solve the problems of lack of centering mechanism, uneven cloth roll, lack of dust removal function, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

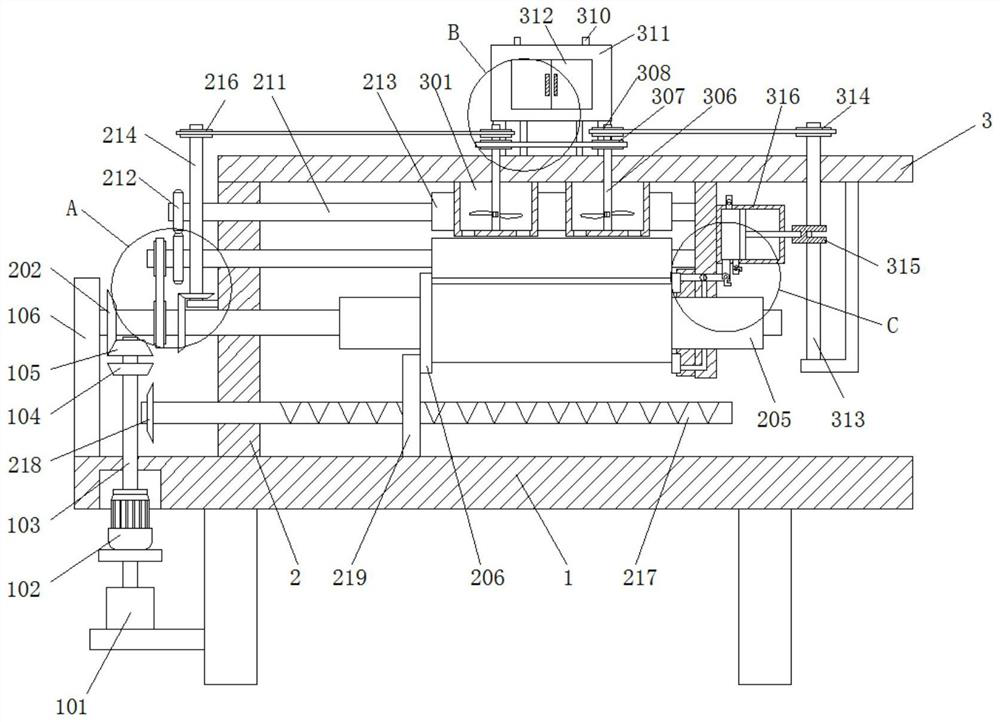

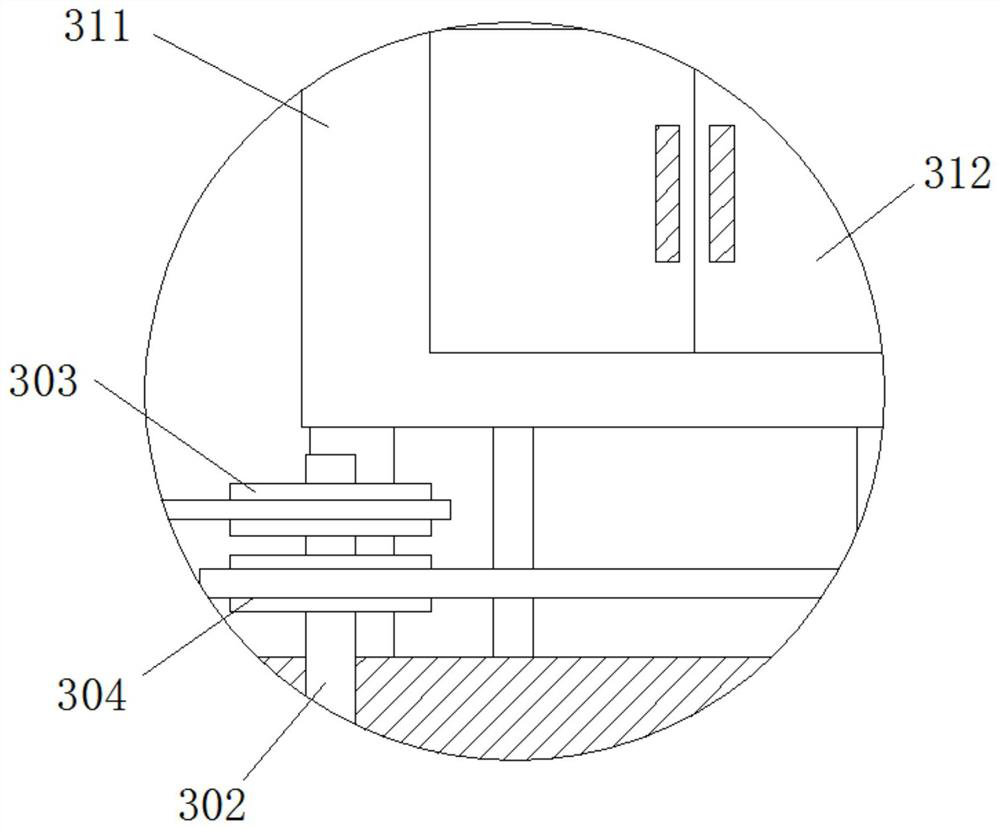

[0037] refer to Figure 1-6 , a cloth rolling device with a centered structure for textile use, comprising a workbench 1, a support plate 106 and a vertical plate 2 are fixedly connected to the top of the workbench 1, a top plate 3 is fixedly connected to the top of the vertical plate 2, the support plate 106 and the vertical plate are fixedly connected The plate 2 is rotatably connected with a second rotating shaft 201, and the second rotating shaft 201 is fixedly connected with a cloth rolling roller 205. The cloth rolling roller 205 is provided with a centering mechanism, the bottom of the top plate 3 is provided with a cleaning mechanism, and the vertical plate 2 is provided with a For the cloth lowering mechanism, the bottom side wall of the workbench 1 is provided with a motor 102 for driving the centering mechanism, the dust cleaning mechanism and the lower cloth mechanism.

[0038] The bottom side wall of the workbench 1 is fixedly connected with a cylinder 101, the ou...

Embodiment 2

[0042] refer to figure 1 , image 3 and Figure 5 , a cloth rolling device with a centered structure for textile use, comprising a workbench 1, a support plate 106 and a vertical plate 2 are fixedly connected to the top of the workbench 1, a top plate 3 is fixedly connected to the top of the vertical plate 2, the support plate 106 and the vertical plate are fixedly connected The plate 2 is rotatably connected with a second rotating shaft 201, and the second rotating shaft 201 is fixedly connected with a cloth rolling roller 205. The cloth rolling roller 205 is provided with a centering mechanism, the bottom of the top plate 3 is provided with a cleaning mechanism, and the vertical plate 2 is provided with a For the cloth lowering mechanism, the bottom side wall of the workbench 1 is provided with a motor 102 for driving the centering mechanism, the dust cleaning mechanism and the lower cloth mechanism.

[0043] The bottom side wall of the workbench 1 is fixedly connected wit...

Embodiment 3

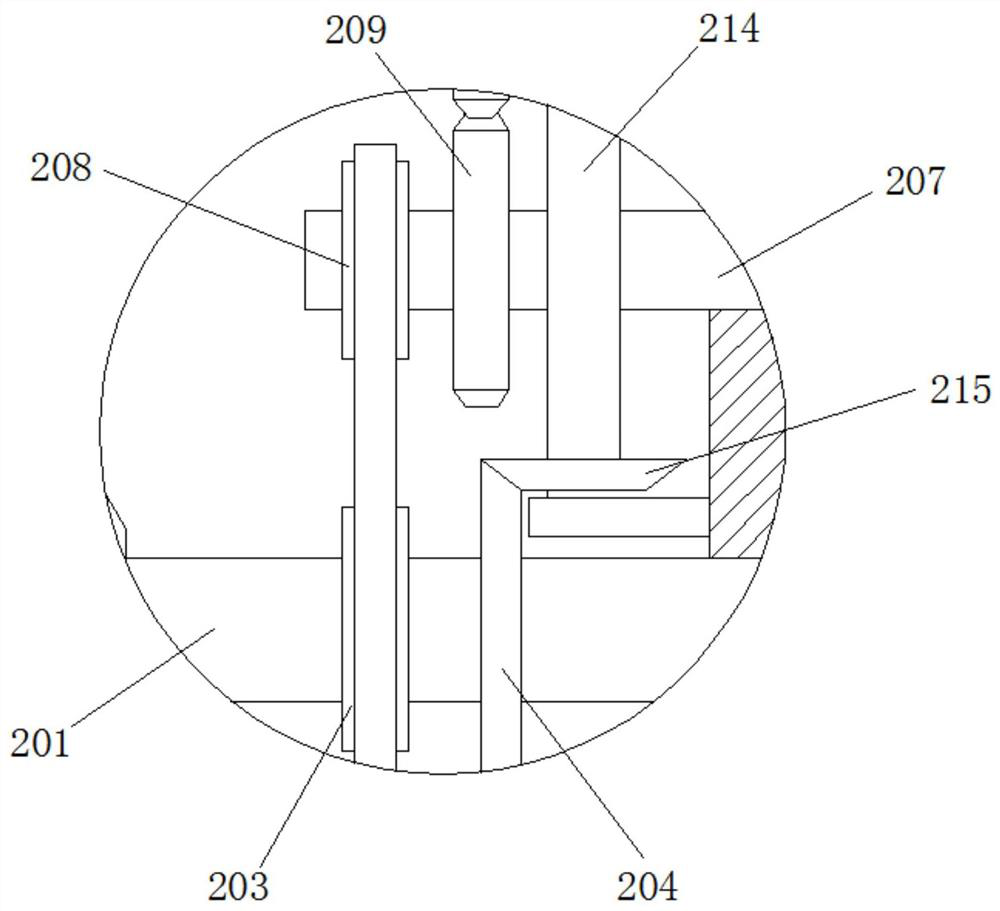

[0048] refer to figure 1 , figure 2 , Figure 4 , Figure 5 and Figure 6 , a cloth rolling device with a centered structure for textile use, comprising a workbench 1, a support plate 106 and a vertical plate 2 are fixedly connected to the top of the workbench 1, a top plate 3 is fixedly connected to the top of the vertical plate 2, the support plate 106 and the vertical plate are fixedly connected The plate 2 is rotatably connected with a second rotating shaft 201, and the second rotating shaft 201 is fixedly connected with a cloth rolling roller 205. The cloth rolling roller 205 is provided with a centering mechanism, the bottom of the top plate 3 is provided with a cleaning mechanism, and the vertical plate 2 is provided with a For the cloth lowering mechanism, the bottom side wall of the workbench 1 is provided with a motor 102 for driving the centering mechanism, the dust cleaning mechanism and the lower cloth mechanism.

[0049] The centering mechanism includes a ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com