Polypropylene preparation method suitable for gas-phase polymerization process

A polypropylene and production method technology, applied in the field of resin product production, can solve problems such as large single-line production capacity, and achieve the effects of improving efficiency, improving the efficiency of raw material use, and improving the sensitivity of hydrogen adjustment

Active Publication Date: 2021-04-09

朴烯晶新能源材料(上海)有限公司

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Large single-line production capacity

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

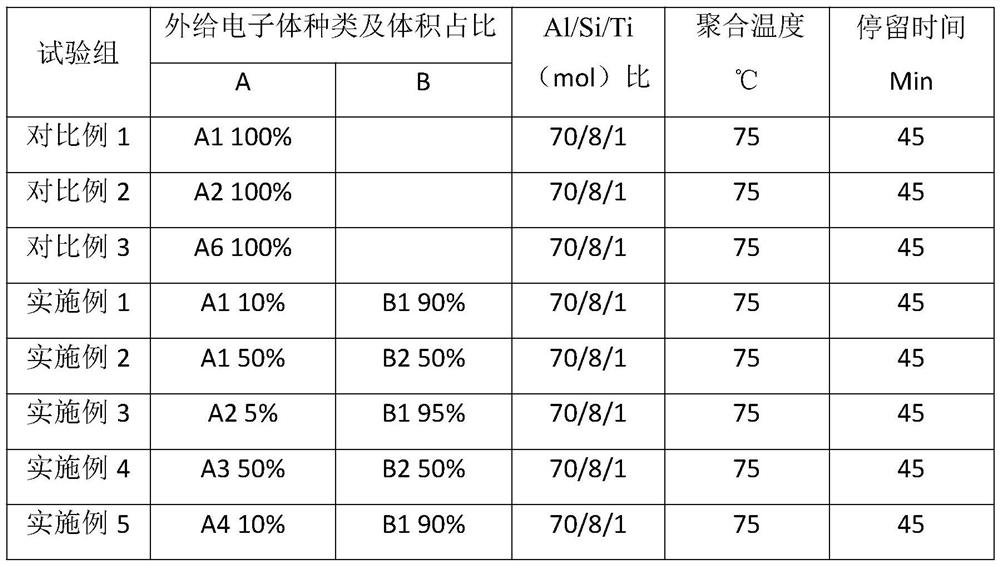

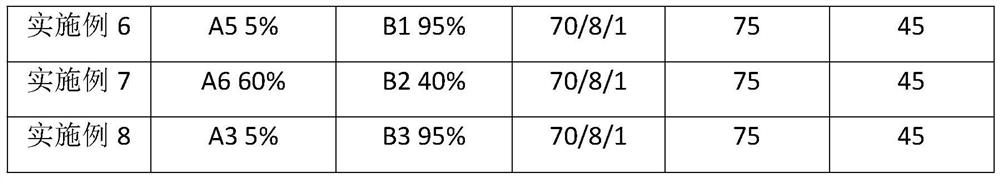

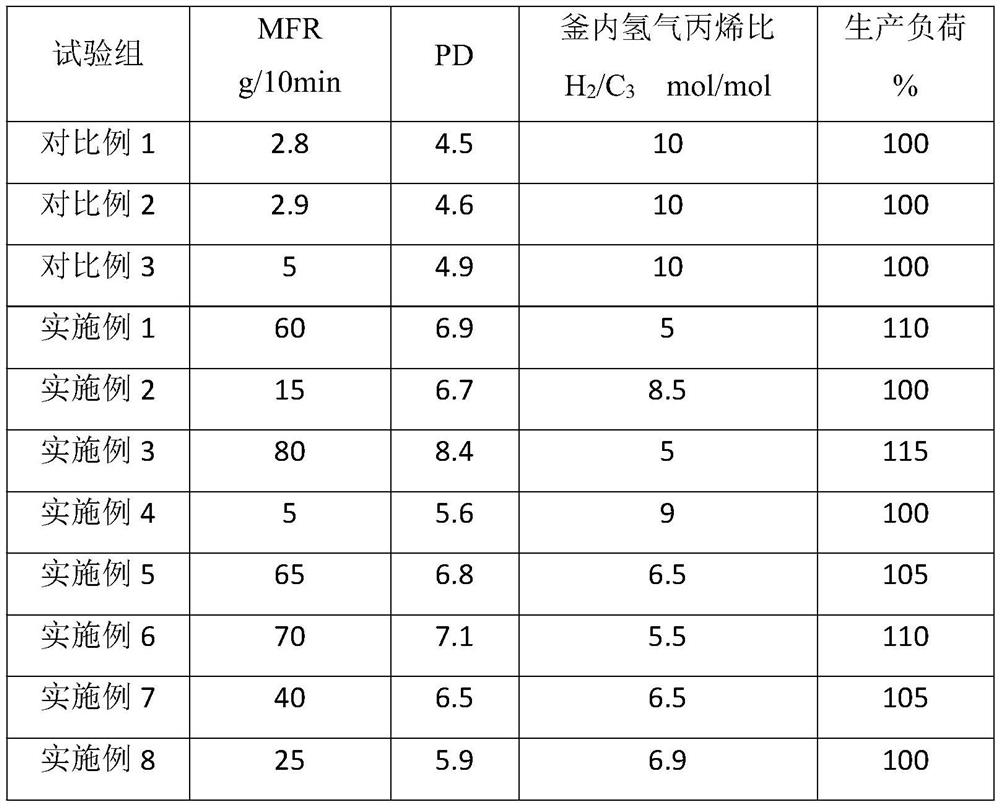

[0022] Embodiment: use Unipol single reactor, use conventional Z-N catalyst, triethylaluminum and a kind of A external electron donor and a kind of B external electron donor, Al / Si / Ti (mol) ratio is controlled at (30 -150) / (5-20) / 1, the polymerization temperature is controlled at 66-88° C., and the average residence time is controlled at 25-85 minutes.

[0023] Table 2 Test group record table

[0024]

[0025]

[0026]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention aims to provide a production method for preparing a polypropylene product with wide relative molecular mass distribution in a single kettle on a gas-phase fluidized bed device, which comprises the following steps: updating or replacing the variety and dosage of an existing external electron donor, and mixing two or more components according to a certain proportion to obtain a component catalytic system, so that the product with wide relative molecular mass can be obtained, and meanwhile, and relatively low hydrogen consumption during production of a high-flow product is realized, so that the partial pressure of ethylene, propylene and the like in the polymerization gas is increased under the condition of not increasing the total pressure of the reactor, and the polymerization efficiency is further improved.

Description

technical field [0001] The invention relates to a method for preparing polypropylene products for injection molding, which can solve the problems of relatively narrow molecular weight and poor processability of polymer products obtained in the existing single-pot gas-phase polypropylene production process, and can be used at the same time Improve the hydrogen adjustment sensitivity of the polymerization system, reduce the proportion of non-condensable gases such as hydrogen, and increase the composition of the reaction gas, thereby improving the polymerization efficiency. At the same time, the device can be kept running stably for a long period, and belongs to the technical field of resin product production. Background technique [0002] Polypropylene is one of the five general-purpose plastics and is widely used in fields such as injection molding, blow molding and film. At present, the production process of polypropylene is mainly fluidized bed gas phase method, loop pipe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08F110/06C08F2/34C08F4/646

CPCC08F110/06C08F4/6465C08F2/34C08F2500/04

Inventor 张文龙董小攀王艳丽

Owner 朴烯晶新能源材料(上海)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com