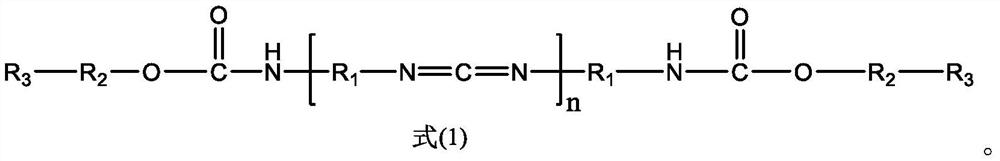

Polycarbodiimide crosslinking agent, its preparation method, application, and composition containing it

A polycarbodiimide and cross-linking agent technology, applied in organic chemistry, coating, etc., can solve problems such as low reactivity, poor substrate adhesion, and coating hardness that cannot meet the requirements, and meet equipment requirements Low cost, low cost, good alcohol resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

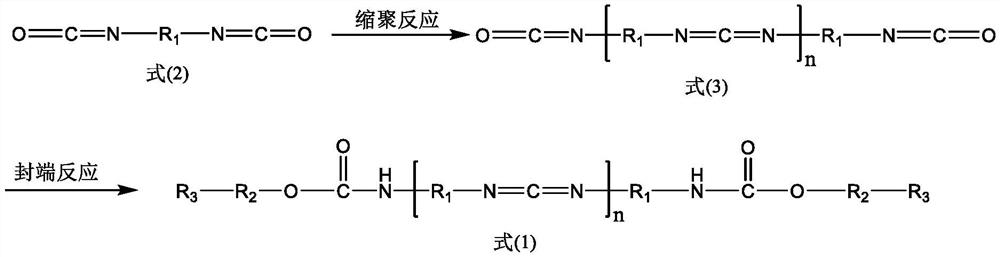

Method used

Image

Examples

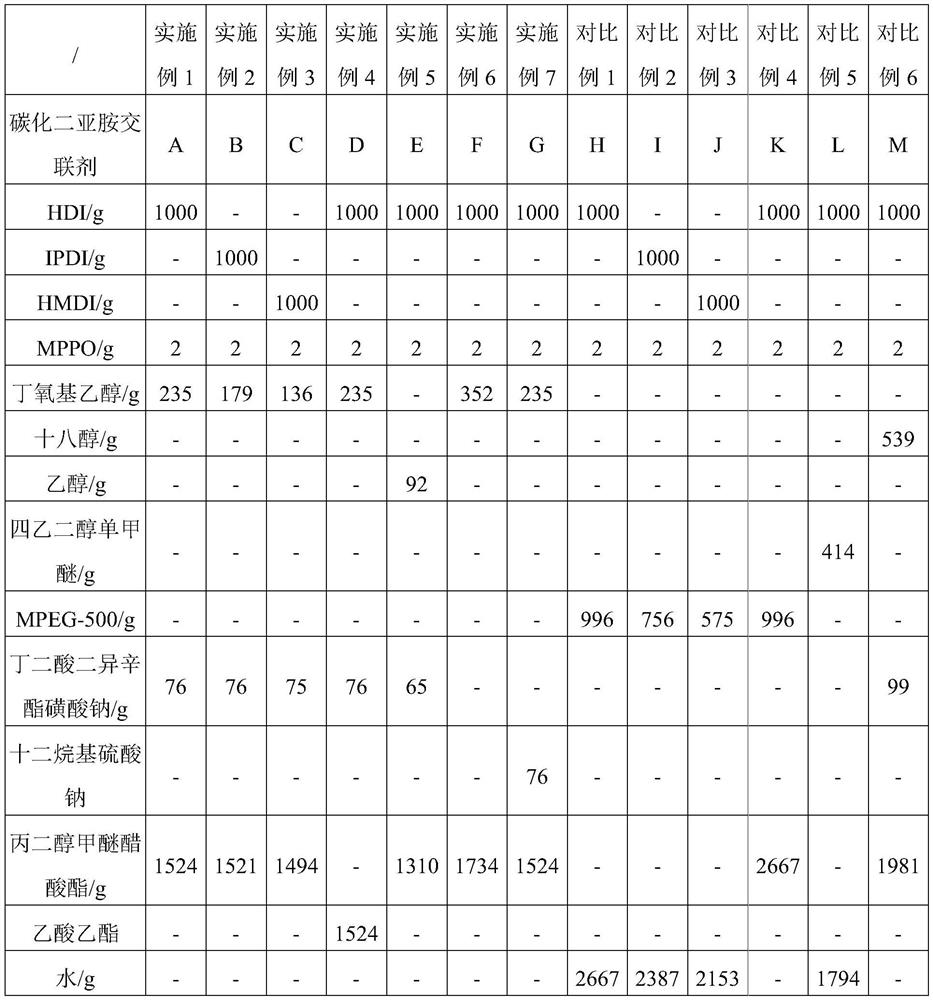

Embodiment 1

[0079] Add 1000g of hexamethylene diisocyanate (HDI) into a 5L three-necked flask, protect it with nitrogen gas, add 2g of 3-methyl-1-phenyl-2-phosphene-1-oxide (MPPO), and keep at 160°C The reaction was carried out for 8 hours to obtain a HDI prepolymer (0.99mol) with a degree of polymerization of about 5. The temperature of the system was lowered to 120° C., 235 g (1.99 mol) of butoxyethanol was added, and the reaction was carried out for 2 hours. The NCO value of the system dropped to 0, and 1016 g of polycarbodiimide compound was obtained. Get 76g diisooctyl sulfonate sodium succinate and dissolve and disperse in 1524g propylene glycol methyl ether acetate (solubility parameter is 9.4), join in the polycarbodiimide compound while stirring, after stirring for 1h, the solid content obtained is 40 % translucent liquid, which is the final highly reactive water-soluble polycarbodiimide crosslinker A.

Embodiment 2

[0081] Add 1000g of isophorone diisocyanate (IPDI) into a 5L three-necked flask, protect it with nitrogen gas, add 2g of 3-methyl-1-phenyl-2-phosphene-1-oxide (MPPO), at 160°C After 12 hours of reaction, an IPDI prepolymer (0.75 mol) with a degree of polymerization of about 5 was obtained. The temperature of the system was lowered to 120° C., 179 g (1.51 mol) of butoxyethanol was added, and the reaction was carried out for 2 hours. The NCO value of the system dropped to 0, and 1014 g of polycarbodiimide compound was obtained. Get 76g of diisooctyl sulfonate sodium succinate and dissolve and disperse it in 1521g of propylene glycol methyl ether acetate (solubility parameter is 9.4), join in the polycarbodiimide compound while stirring, after stirring for 1h, the solid content is 40 % translucent liquid, which is the final highly reactive water-soluble polycarbodiimide crosslinker B.

Embodiment 3

[0083] Add 1000g of dicyclohexylmethane diisocyanate (HMDI) to a 5L three-necked flask, protect it with nitrogen gas, add 2g of 3-methyl-1-phenyl-2-phosphene-1-oxide (MPPO), and heat at 160°C The reaction was carried out for 24 hours to obtain a HMDI prepolymer (0.63mol) with a degree of polymerization of about 5. The temperature of the system was lowered to 120° C., 150 g of butoxyethanol (1.27 mol) was added, and the reaction was carried out for 2 hours. The NCO value of the system dropped to 0, and 996 g of polycarbodiimide compounds were obtained. Get 75g diisooctyl sulfonate sodium succinate and dissolve and disperse in 1494g propylene glycol methyl ether acetate, join in the polycarbodiimide compound while stirring, obtain the translucent liquid that solid content is 40% after stirring 1h, That is the final highly reactive water-soluble polycarbodiimide crosslinker C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com