Cotton kneading machine for processing super-soft cotton yarn

A technology of ultra-soft and cotton rubbing machine, which is applied in fabric rubbing/softening treatment, textile and paper making, fabric surface trimming, etc., and can solve problems such as health damage to workers, low processing efficiency, and impact on surrounding air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

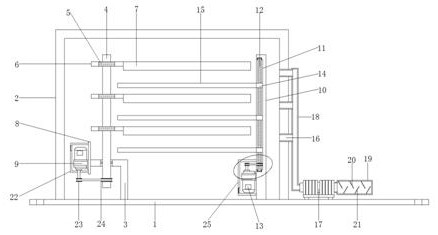

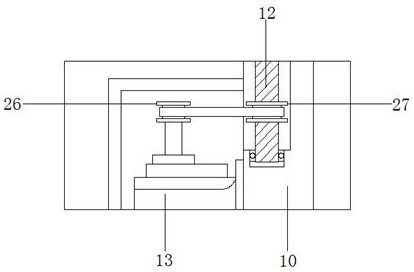

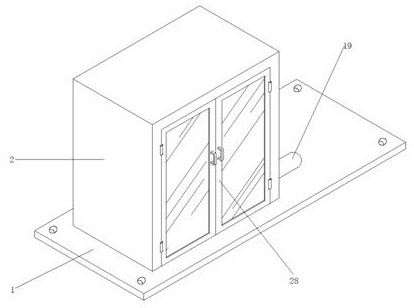

[0022]Example 1, referenceFigure 1-4, A small soft cotton yarn processing kneading machine, including the bottom plate 1, the top of the bottom plate 1 is opened, and the outer wall of the bottom plate 1 is provided with a dust cover 2, and the dust cover 2 side has an installation. The mouth, and the inner wall of the mounting port is hinged with a door panel 28 with a transparent viewing window, and the upper outer wall of the bottom plate 1 is welded to the L-plate 3, the outer wall of the L-plate 3 top outer wall is inserted with the bearing 4, and the rod 4 The connecting plate 6 is attached to the outer distance distribution through the eccentric bearing 5, and the connecting plate 6 side is welded to the block 7, the pressure plate 7 and the retaining plate 15 mutually intertroad, and the first baffle 20 and the second baffle 21 are intertwined. Mutual interleaved setting, and the outer wall of the L-plate 3 side is welded to have a mounting plate 8, and the outer wall of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com