Rib belt nested geogrid for pile net structure

A technology for geogrids and structures, applied in infrastructure engineering, soil protection, roads, etc., can solve the problems of less improvement in geogrid structures and non-compliance with geogrid requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

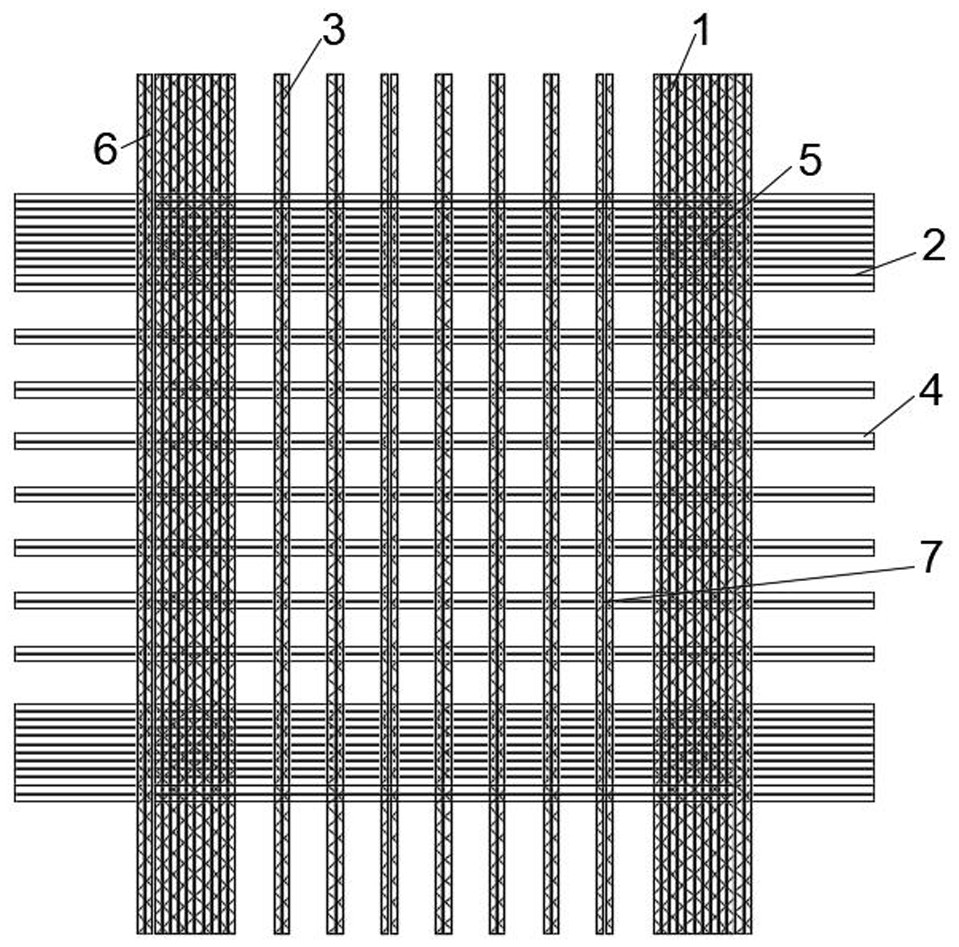

[0018] In order to enable those skilled in the art to better understand the technical solution of the present invention, the following in conjunction with the attached figure 1 And the specific embodiment will further illustrate the present invention.

[0019] as attached figure 1 As shown, a geogrid nested with ribs for a pile network structure includes longitudinal main ribs 1, transverse main ribs 2, longitudinal auxiliary ribs 3 and lateral auxiliary ribs 4, The longitudinal main ribs 1, the transverse main ribs 2, the longitudinal auxiliary ribs 3 and the transverse auxiliary ribs 4 are respectively composed of a plurality of polyester fiber bundles 6, each of the longitudinal and transverse The polyester fiber bundles 6 are arranged in parallel and side by side, the longitudinal and transverse polyester fiber bundles 6 form two planes up and down, and the interweaving of the longitudinal main stress ribs 1 and the transverse main stress ribs 2 forms the main stress by b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com