Rammed earth wall formwork erecting and ramming integrated construction device

A technology for construction devices and rammed earth walls, which is applied in the direction of formwork/formwork/work frames, walls, building components, etc., can solve the problems of uneven construction quality, inability to guarantee the strength and integrity of walls, and low construction efficiency, and achieve Improve tamping efficiency and quality, good tamping effect and high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

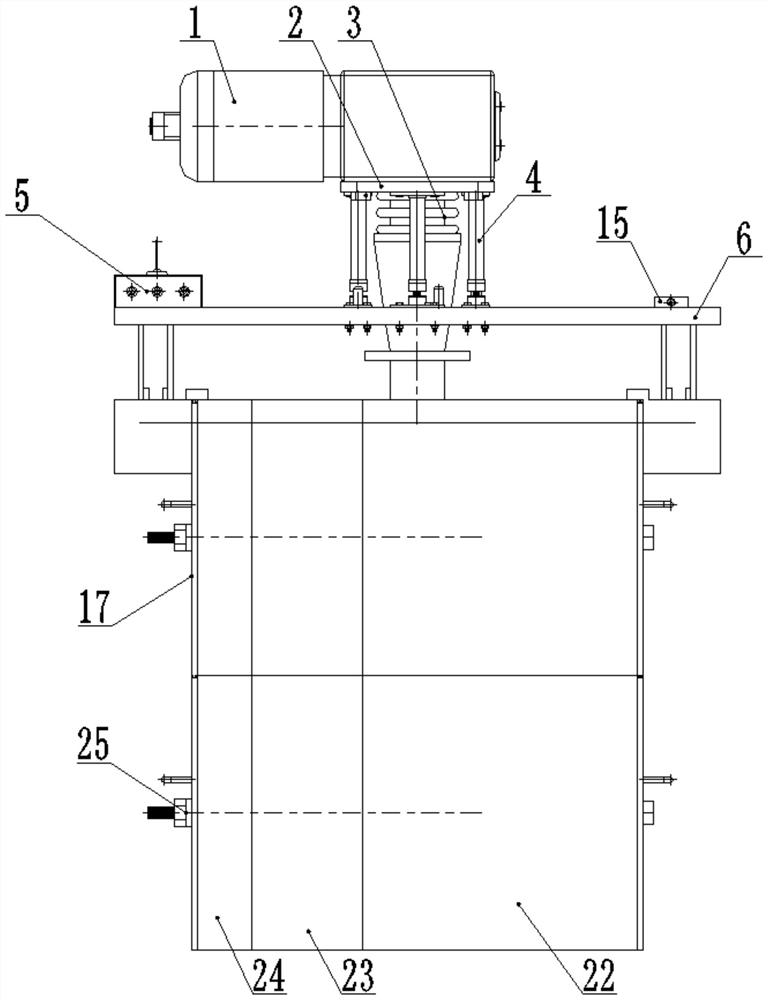

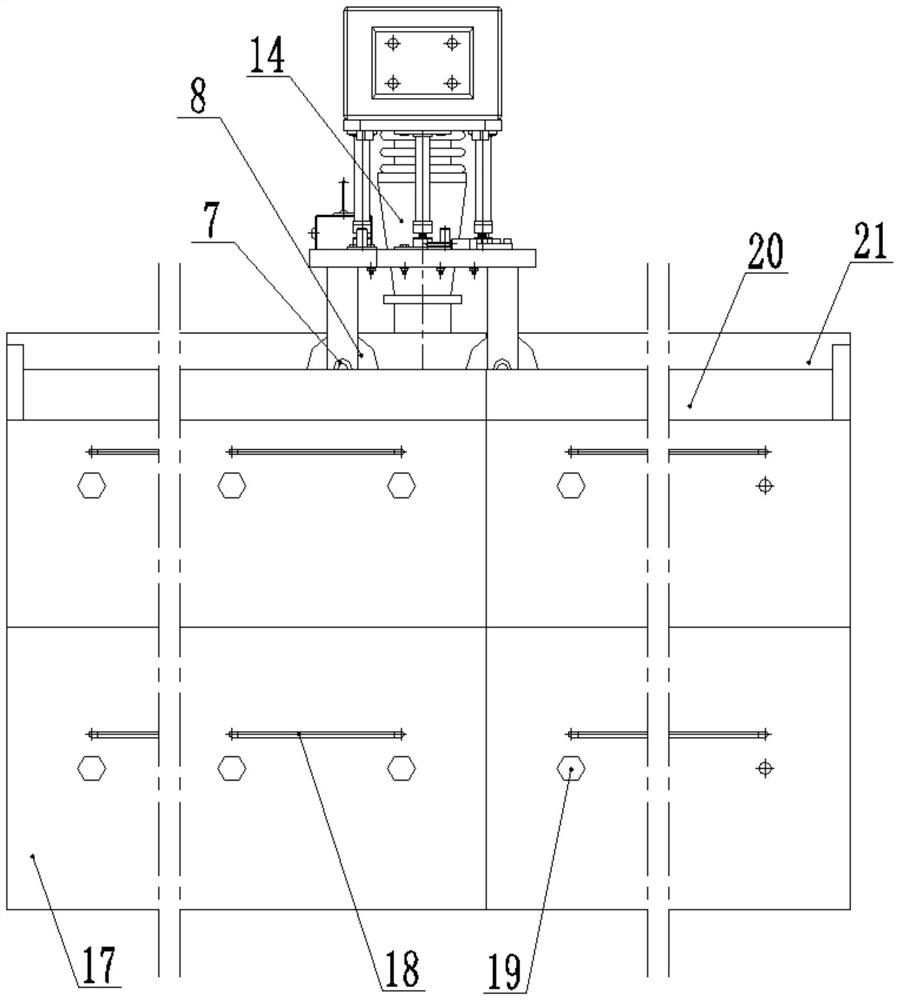

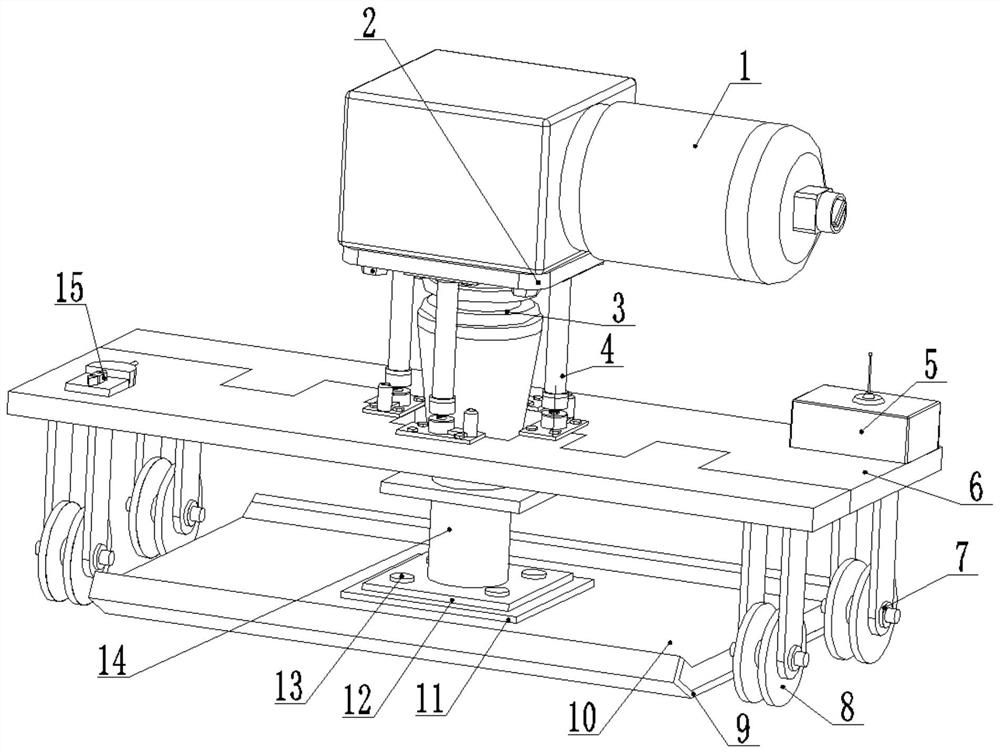

[0030] Referring to each figure, a rammed earth wall formwork support integrated construction device with ramming, the integrated rammed construction device includes an automatic ramming mechanism capable of automatic ramming and a spliced steel film mechanism; the automatic ramming mechanism includes A ramming motor 1, an electric lifting rod 4, a kneading support plate 6, a ramming support member 14, a pressing plate 10 and a four-wheel traveling mechanism 7; the ramming motor 1 is installed on the motor fixing plate 2, and the motor fixing plate 2 The bottom is hinged with the top of the electric lifting rod 4, and the bottom end of the electric lifting rod 4 is installed on the kneading type support plate 6, and the bottom of the kneading type support plate 6 is provided with a four-wheel running mechanism 7, and the four-wheel running mechanism 7 is composed of four electric drive wheels 8 Assembled with the wheel frame; the ramming support 14 is driven by the ramming mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com