Assembly type inner cavity special-shaped formwork structure and mounting and dismounting method

A prefabricated and formwork technology, which is applied in the direction of formwork/formwork/work frame, formwork processing, building structure, etc., can solve the problems of difficult installation and removal of inner cavity formwork, and achieve convenient removal, cost reduction, and speed up. The effect of construction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0027] Example 1. A quick installation method for the inner cavity formwork of a long rectangular hollow concrete member

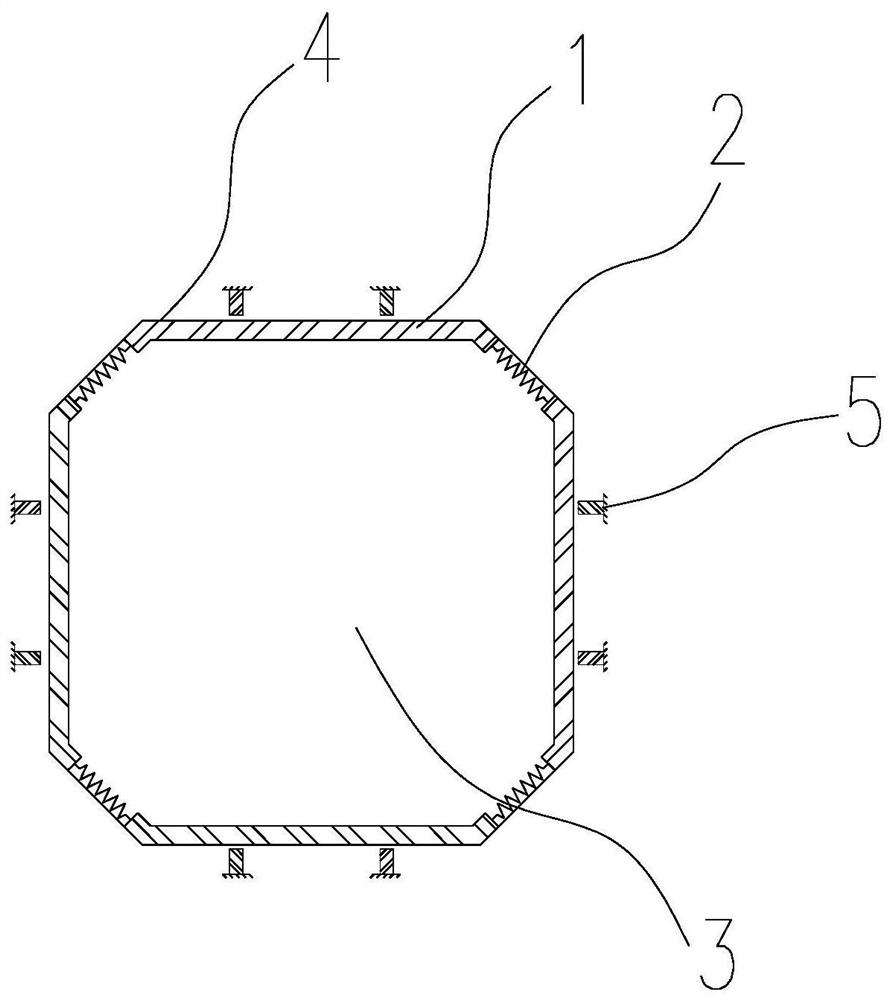

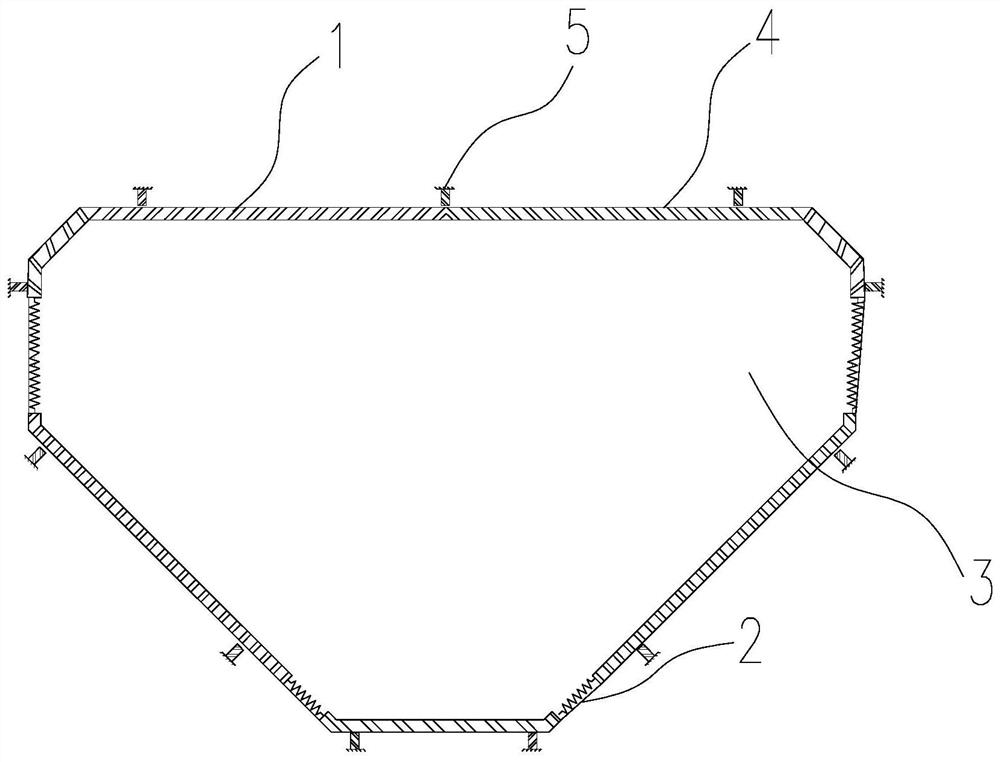

[0028] Figure 4 Shown is a formwork structure diagram when a long rectangular hollow concrete member is poured. To this end, the reinforcement cage of the component is bound first, then hoisted into the outer formwork, and the positioning stopper 5 of the inner cavity formwork is arranged around the reinforcement cage, and then the inner cavity is formed by assembling the rigid formwork 1 and the connecting gusset 2 formwork 3, and the outer side of the inner cavity formwork 3 is wrapped with an insulating material 4, and then penetrated from the inside of the steel cage. More than two positioning stoppers 5 are arranged on the outside of each side of the inner cavity formwork 3, and the positioning stoppers 5 are arranged at a certain interval along the length direction, and bound to the reinforcement cage.

example 2

[0029] Example 2. A quick removal method for the inner cavity formwork of a long rectangular hollow concrete member

[0030] A long rectangular hollow concrete member, when the concrete member is cured for a period of time, the formwork needs to be removed quickly. For this reason, the first step is to open the outer formwork, and remove the formwork at both ends of the concrete; the second step is to apply axial pressure to the small section end of the inner cavity formwork 3, so that the inner formwork 3 of the concrete member is separated from the concrete member; In the third step, the large-section end of the inner cavity formwork 3 is drawn to extract the inner formwork 3 from the concrete member.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com