High-thrust liquid rocket engine and low-power-consumption semi-self-starting method thereof

A liquid rocket and engine technology, which is applied to rocket engine devices, machines/engines, mechanical equipment, etc. It can solve problems such as poor starting quality, inability to reuse engines, and high spin-up power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

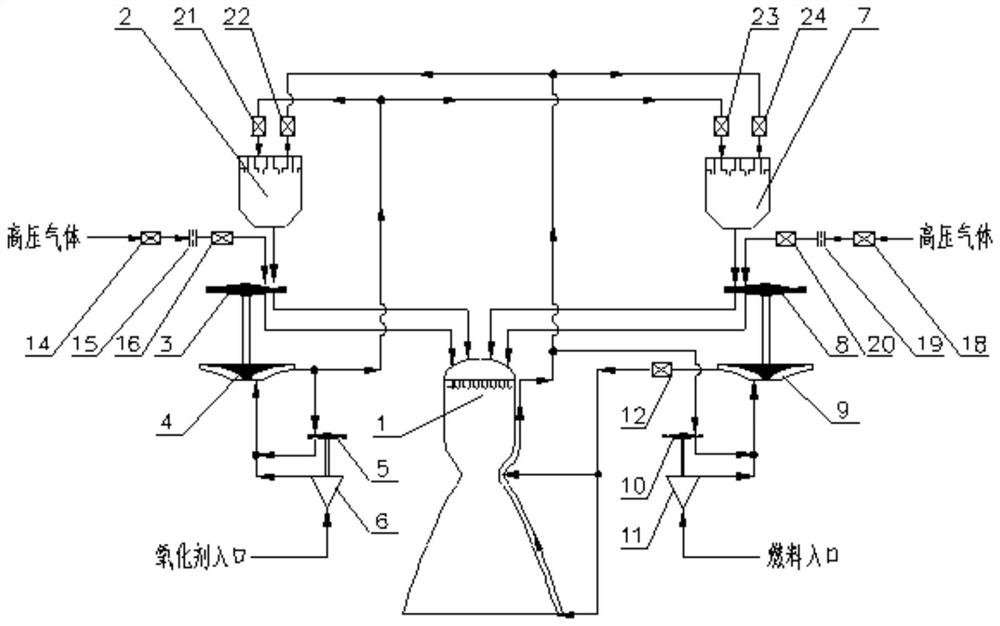

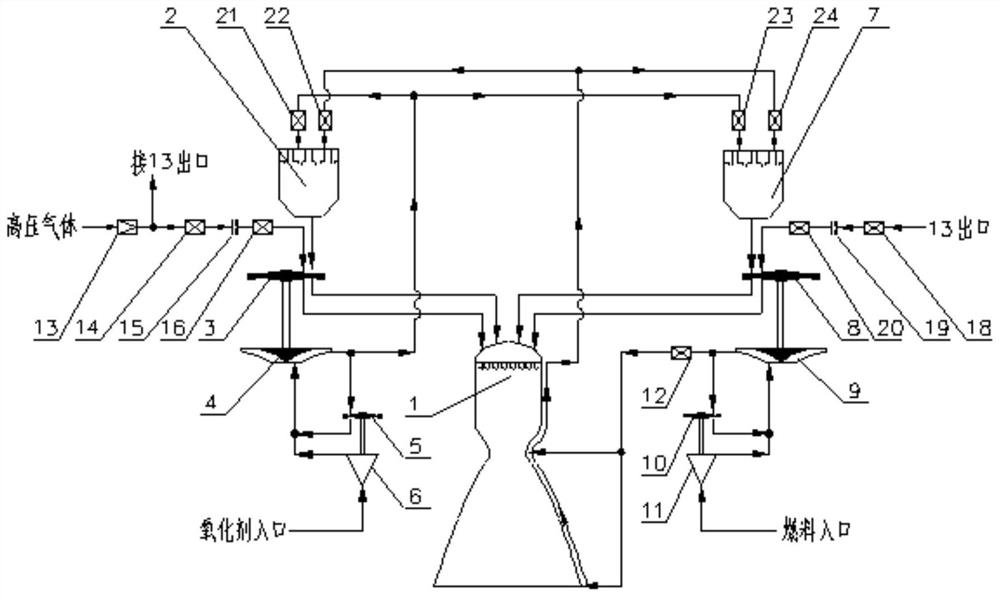

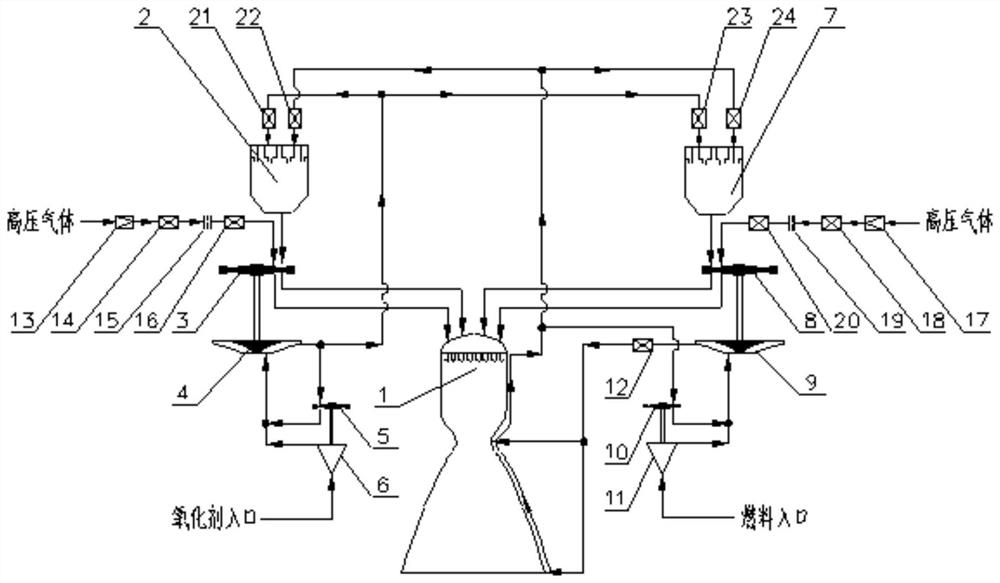

[0107] In order to make the purpose, advantages and features of the present invention clearer, the high-thrust liquid rocket engine proposed by the present invention and its low-power semi-self-starting method will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0108] A high-thrust liquid rocket engine provided by the present invention includes two sets of main turbine pumps. The turbine works, and drives the oxygen pump (or fuel pump) to rotate. After the driving, the gas enters the thrust chamber through the pipeline, where further combustion reaction (supplementary combustion) occurs, and is ejected from the nozzle to generate thrust. Specific as figure 1 , figure 2 , image 3 As shown, the engine includes a gas system, an oxidant supply system, a fuel supply system and a starting system.

[0109] The gas system includes a thrust chamber 1, a first gas generator 2, a second gas generator 7, a first main tur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com