A Centrifugal Wind Wheel with Drag Reduction and Noise Reduction

A centrifugal wind wheel and drag drop technology, which is applied to parts of pumping devices for elastic fluids, non-variable pumps, pump components, etc., can solve the problem of not achieving drag reduction and noise reduction, unable to weaken eddy currents, and noise reduction The effect is limited and other problems, to achieve the effect of reducing the intensity and pressure pulsation amplitude, accelerating the attenuation of vortex, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to make the purpose, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the embodiments, but the claimed scope of the present invention is not limited to the following specific embodiments.

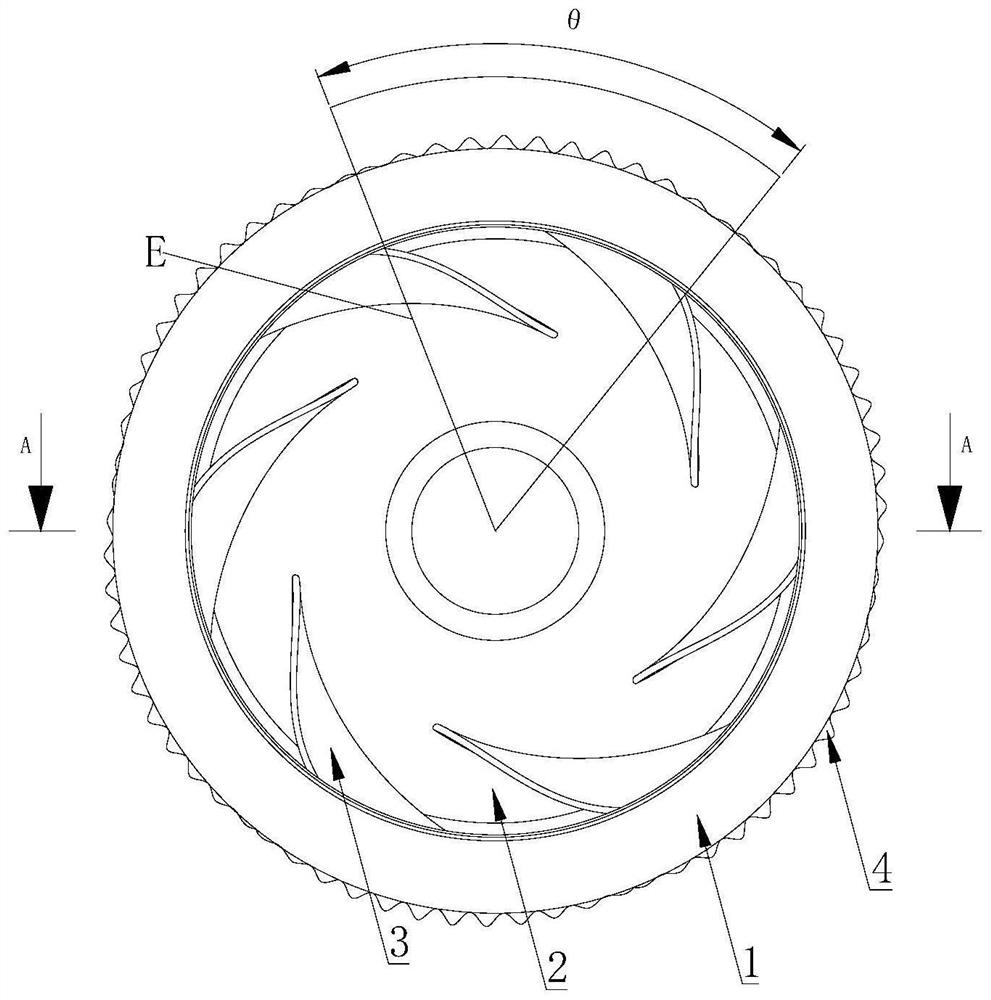

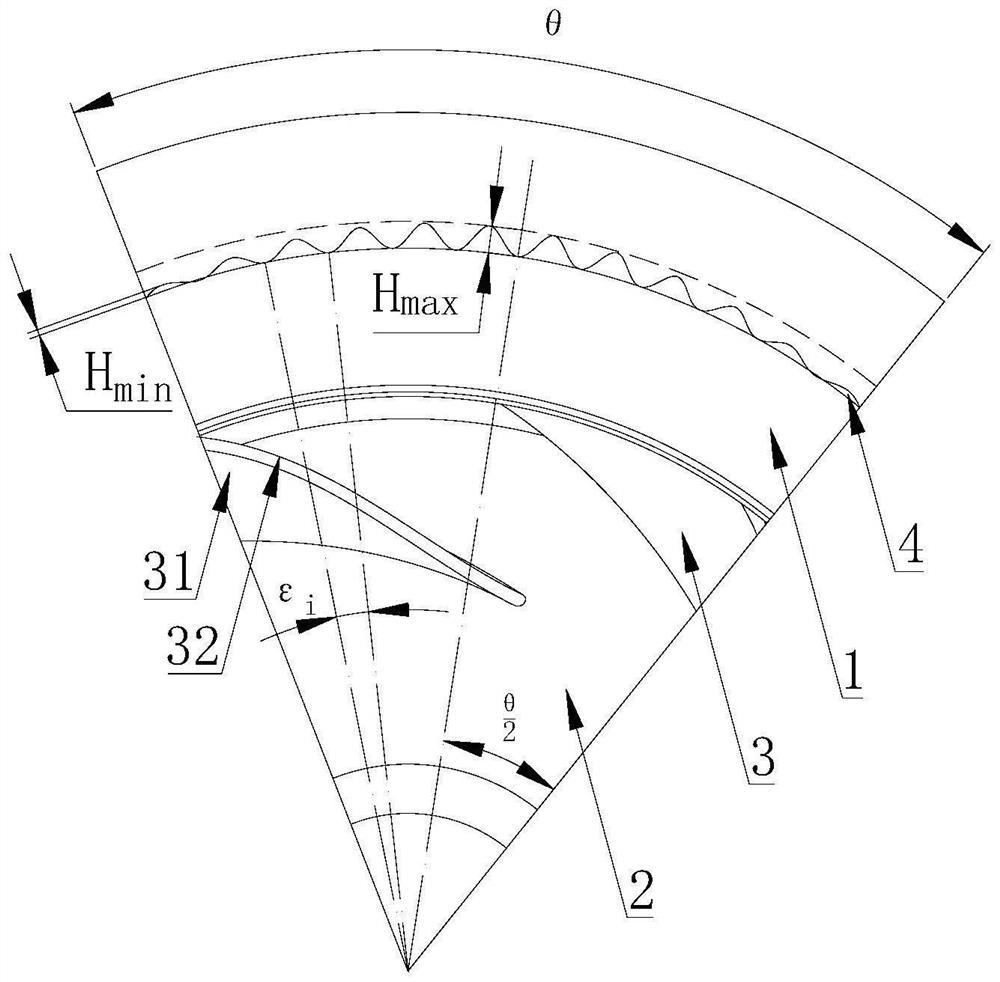

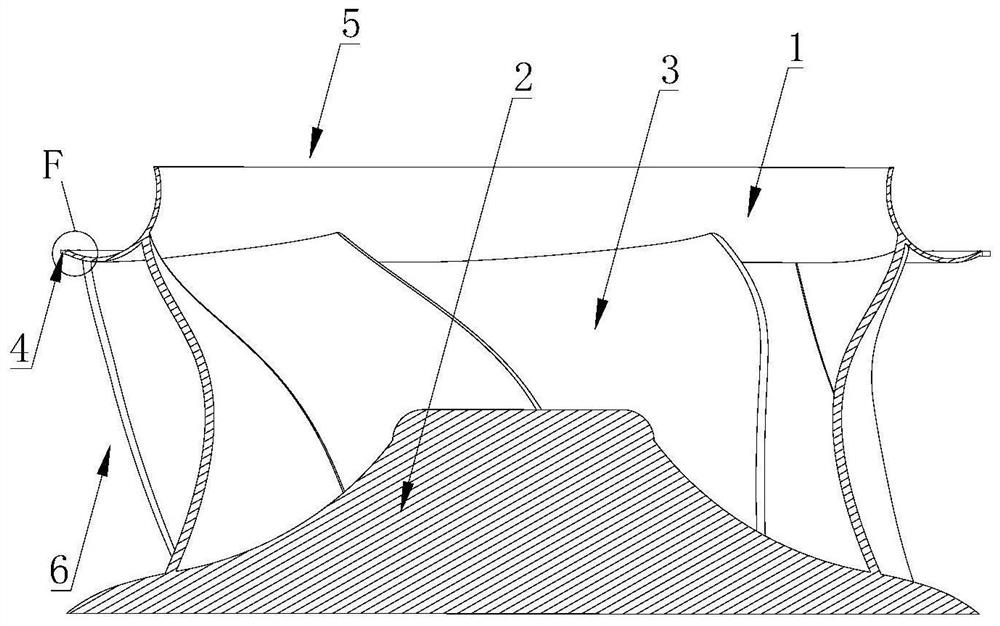

[0045] refer to Figure 1-16 , this embodiment discloses a centrifugal wind wheel with drag reduction and noise reduction, including a wheel cover 1, a plurality of blades 3 and a wheel disc 2, the wheel cover 1 and the wheel disc 2 are coaxially arranged, and the wheel cover 1 and the wheel disc 2 The blades 3 are arranged at intervals in the axial direction, and a plurality of blades 3 are arranged between the wheel cover 1 and the wheel disc 2. The top end of the blade 3 is connected to the wheel cover 1, the bottom end of the blade 3 is connected to the wheel disc 2, and the blades 3 are arranged at intervals in the circumferential direction. Specifically, the wheel cove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com