UPVC composite drain pipe production equipment and using method thereof

A technology for production equipment and drainage pipes, which is applied in the field of UPVC composite drainage pipe production equipment, can solve the problems of insufficient accumulation and mixing of materials, affecting production quality, etc., and achieve the effect of facilitating pressure relief, improving stirring effect and improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

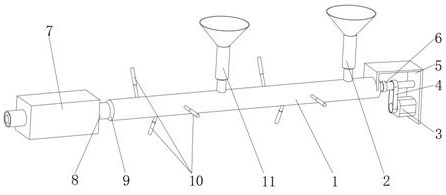

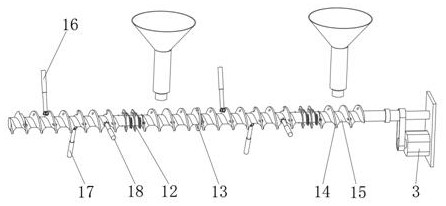

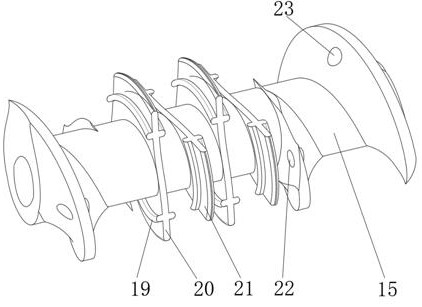

[0045] A kind of UPVC composite drainage pipe production equipment, such as Figure 1-7 As shown, it includes an extrusion chamber 1, two groups of stirring mechanisms 12 and a feeding mechanism; the outer wall of one side of the extrusion chamber 1 is fixed with a mounting frame 5 by bolts, and the outer wall of one side of the mounting frame 5 is installed with a motor 3 through a motor base. The output end of the motor 3 is rotatably connected to the extrusion main shaft 15 through the gear chain transmission assembly 4. One end of the extrusion main shaft 15 is installed on the outer wall of one side of the mounting frame 5 through a bearing seat. The surface of the extrusion main shaft 15 is processed with discontinuous extrusion The thread 14 and the stirring mechanism 12 are respectively arranged between the two extruding threads 14; the motor 3 can drive the extruding main shaft 15 to rotate through the gear chain transmission assembly 4, and then realize it under the a...

Embodiment 2

[0055] A method for using UPVC composite drainage pipe production equipment, comprising the steps of:

[0056] S1: The staff turns on the power of each electrical device, so that the rod heating mechanism 10 and the heating core 25 are preheated;

[0057] S2: add the main material through the main material feeding chamber 2, the electric feeding screw 30 rotates to convey the main material, and the stirring column 28 follows the rotation, and the main material is initially stirred;

[0058] S3: The main material reaches the extrusion chamber 1 through the transportation of the electric feeding screw 30, the stirring of the stirring column 28 and the guidance of the guide groove 29. The extrusion spindle 15 is controlled by the motor 3 to rotate, and the extrusion thread 14 is used to pair the falling The main material is conveyed, and the main material is heated in real time through the heating core 25;

[0059] S4: The main material arrives at the stirring mechanism 12 close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com