A locking piece, a curved surface mount connector and a connector assembly

A connector assembly and connector technology, which is applied to the components, connections, and fixed connections of connecting devices, can solve the problem that pins and pads cannot be well fitted, pins and pads cannot be completely fitted, and Problems such as virtual welding of connector pins, to achieve the effect of extensive use value, increase separation force, and reduce vibration and impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, characteristics and details of the curved surface-mount connector proposed according to the present invention will be described below in conjunction with the accompanying drawings and preferred embodiments. Its effect is described in detail below.

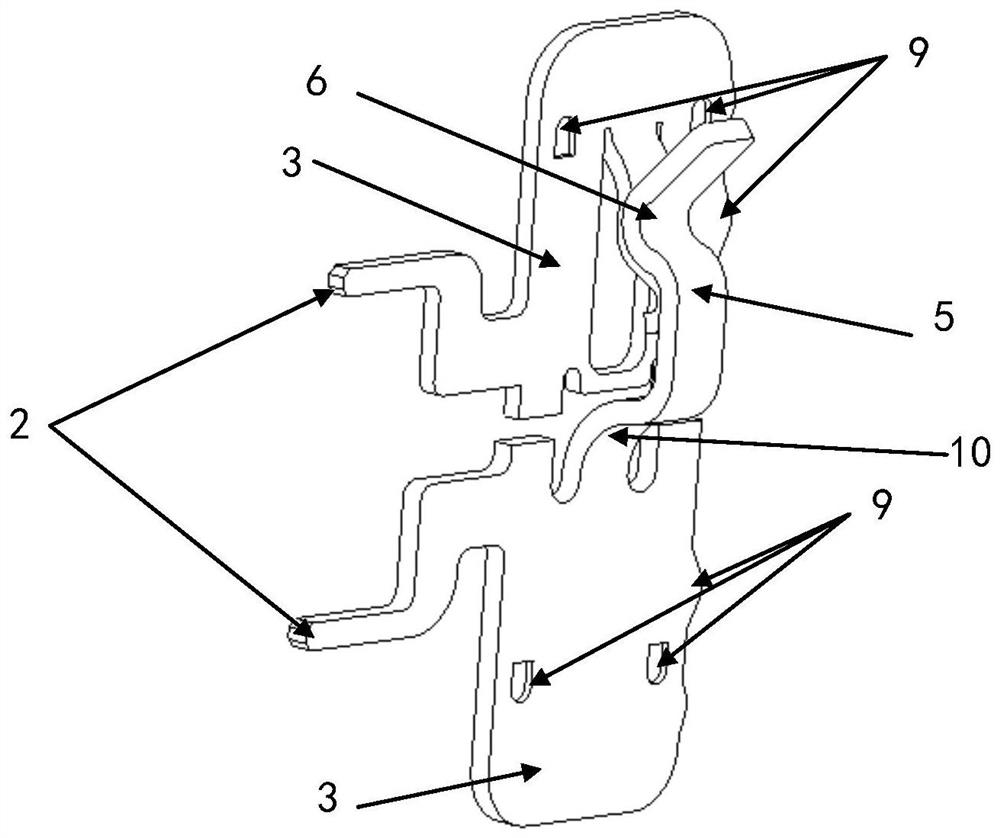

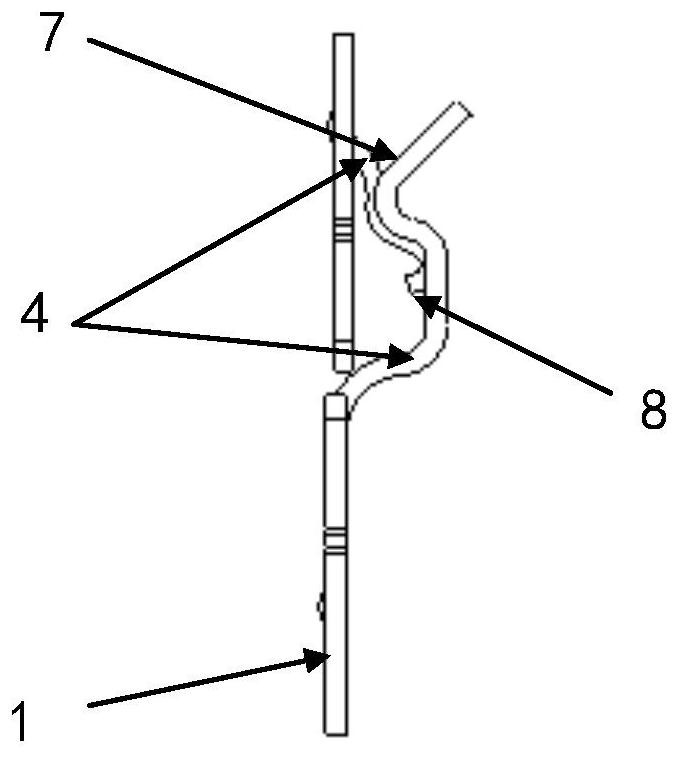

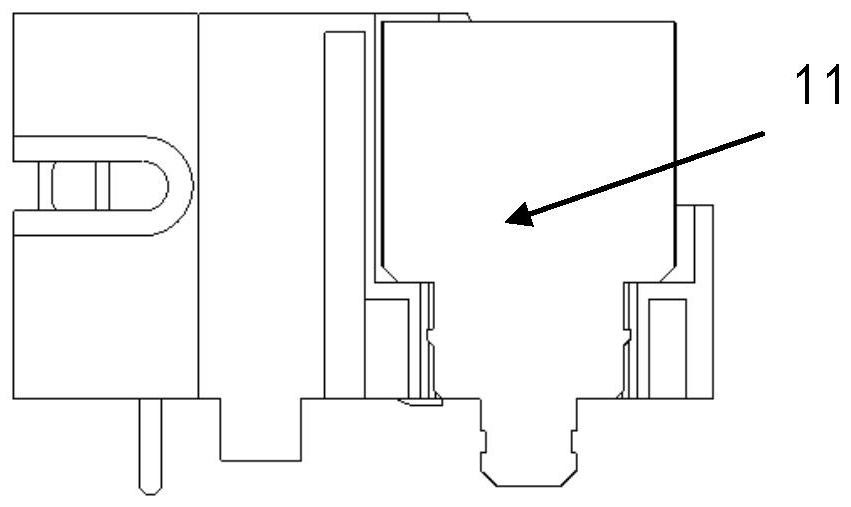

[0035] see Figure 1-3 , which is a structural schematic diagram of each part of the curved surface-mount connector of the present invention, the curved surface-mount connector includes a locking piece 1 for realizing its insertion and locking, and the locking piece 1 includes welding of the curved connection end 2 and the plug-in locking end 3, wherein the plug-in locking end is provided with an elastic cantilever 4 for contacting and locking with the locking part of the adapter connector, and the elastic cantilever 4 is provided with at least one The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com