A high-speed backplane connector

A high-speed backplane and connector technology, which is applied in the connection, the parts of the connecting device, the protective grounding/shielding device of the connecting parts, etc., can solve the problems of poor high-speed signal transmission quality and poor shielding effect, and reduce the short pile effect , Improve the effect of reflow, good reflow and shielding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

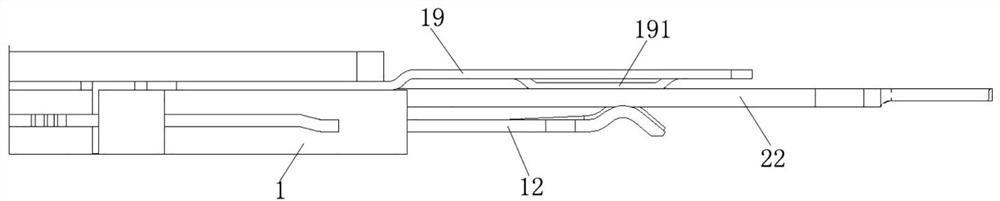

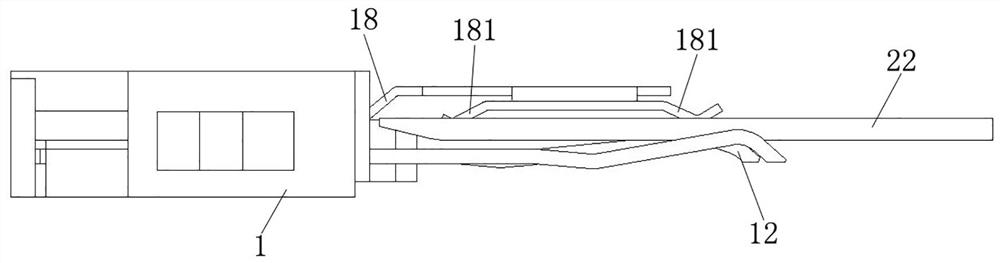

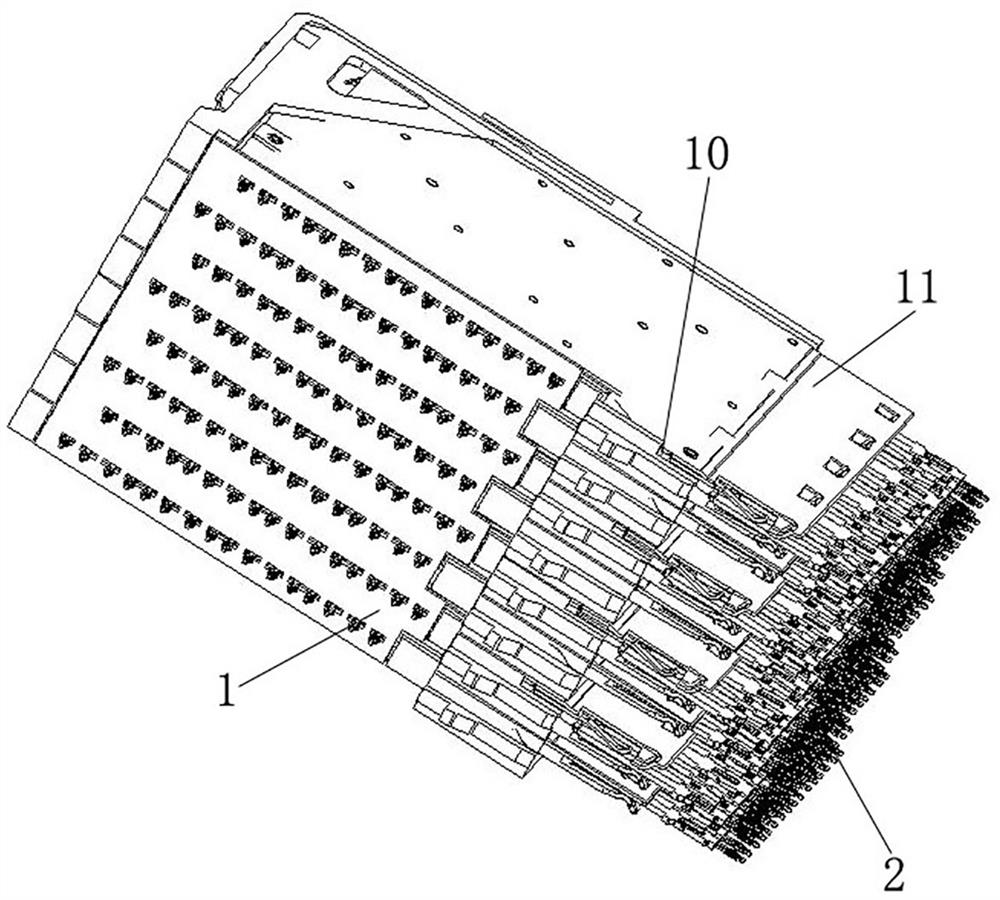

[0033] This embodiment of the high-speed backplane connector incorporates Figure 3-5 for clarification, since Figure 3-5 Both show a schematic diagram of the mating state of the high-speed backplane connector and the adapter connector. In order to clearly distinguish the high-speed backplane connector and the adapter connector, the high-speed backplane connector of this embodiment is referred to as It is a female connector, and the mating connector is called a male connector.

[0034]The female end connector of this embodiment includes a connector housing, and a plurality of plug-in modules 1 are stacked and installed in the connector housing. The plug-in module 1 has an insulator, and contacts arranged in rows are fixedly installed in the insulator. , including a plurality of differential signal pairs arranged at intervals and a female ground contact 12 disposed between two adjacent differential signal pairs. These contacts protrude from one side of the insulator to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com