Multi-face machining device based on multi-way flange

A technology of multi-face processing and multi-pass flanges, which is applied in the direction of positioning devices, feeding devices, metal processing equipment, etc., can solve the problems of poor sealing performance, avoid loose fit, improve accuracy, and avoid offset positions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

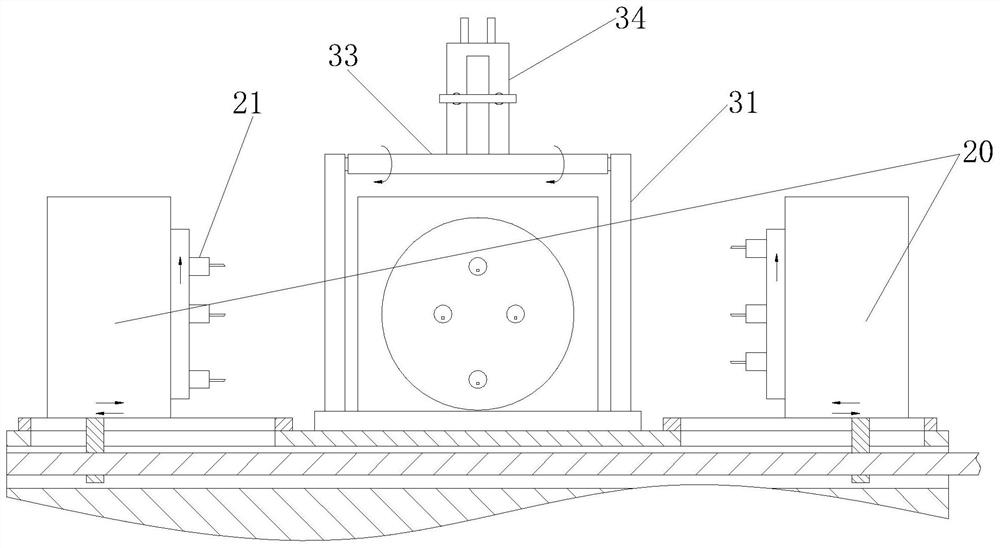

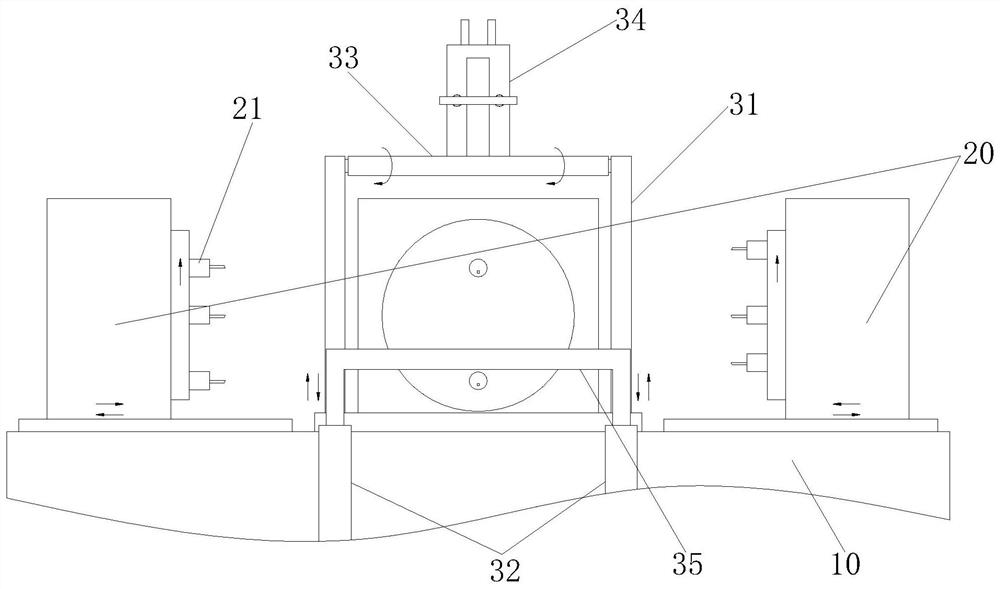

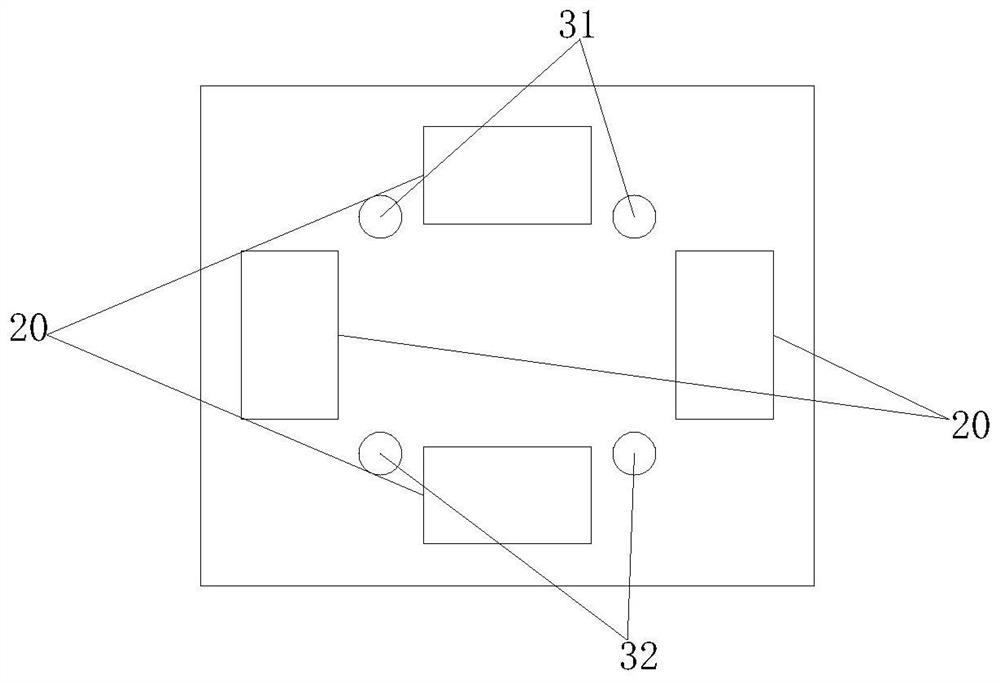

[0021] Such as Figure 1-4 As shown, the multi-face processing device based on the multi-way flange described in this embodiment includes a base 10, two sets of milling mechanisms 20 arranged on the base 10, and a fixing mechanism for fixing the flange. The milling mechanism 20 consists of two The movement direction of the milling unit is opposite, and the movement direction of the two sets of milling mechanisms 20 is vertical; the two milling units of the same set of milling mechanism 20 are connected by the same ball screw, and the thread direction of the connection between the ball screw and the two milling units On the contrary, the rotation of the ball screw driven by the motor drives the two milling units of the same set of milling mechanism 20 to move back or towards each other.

[0022] By arranging two sets of milling mechanisms 20, each set of milling mechanisms 20 includes two milling units to process four faces of the flange fixed by the fixing mechanism at the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com