Phase optical variable anti-counterfeiting element

A technology of optical variable anti-counterfeiting and components, which is applied in the field of anti-counterfeiting and can solve the problems of inability to identify the authenticity of items, economic losses, and difficulty in effectively preventing copying, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

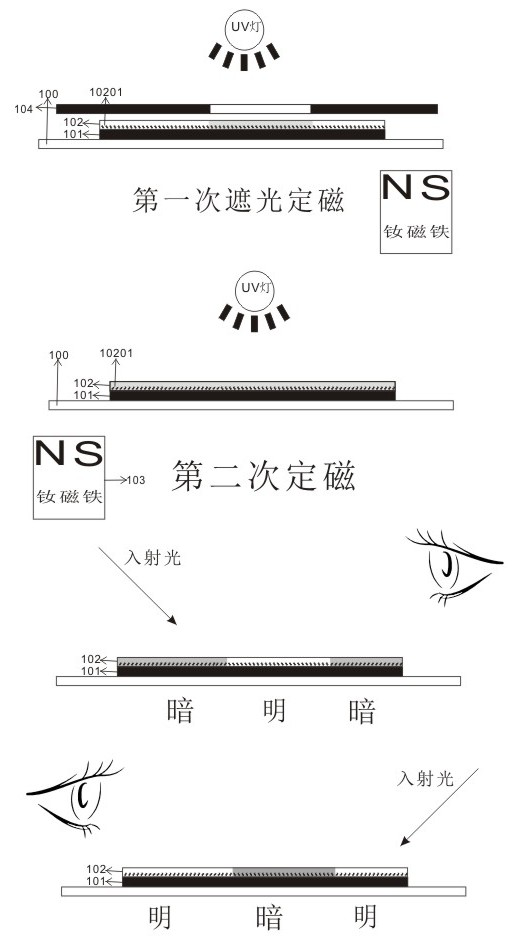

[0018] Prepare materials such as magnetic light-changing ink, hollowed-out visor, etc. First, on the substrate layer, print the dark background layer with inks that have second-line anti-counterfeiting features such as infrared, magnetic, fluorescent, and hidden information; then print the magnetic light-changing UV-curable ink on the dark background layer, which can Through silk screen printing or gravure printing, the printed matter passes through the fixed magnetic device in sequence. When passing through the fixed magnetic device with a light shield for the first time, the magnetic optically variable ink in the hollow part will make the magnetic material into a magnetic material with the irradiation of ultraviolet rays. Phase angle curing, other light-shielding magnetic optically variable inks are not cured and enter the next fixed magnetic device unit. Under the action of an electromagnetic field, the uncured part of the magnetic optically variable pigments is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com