Upper rudder bearing, rudder system and ship

A rudder bearing and steering gear technology, which is applied to the rudder system, ships, and upper rudder bearing fields, can solve the problems of difficulty in installation and maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

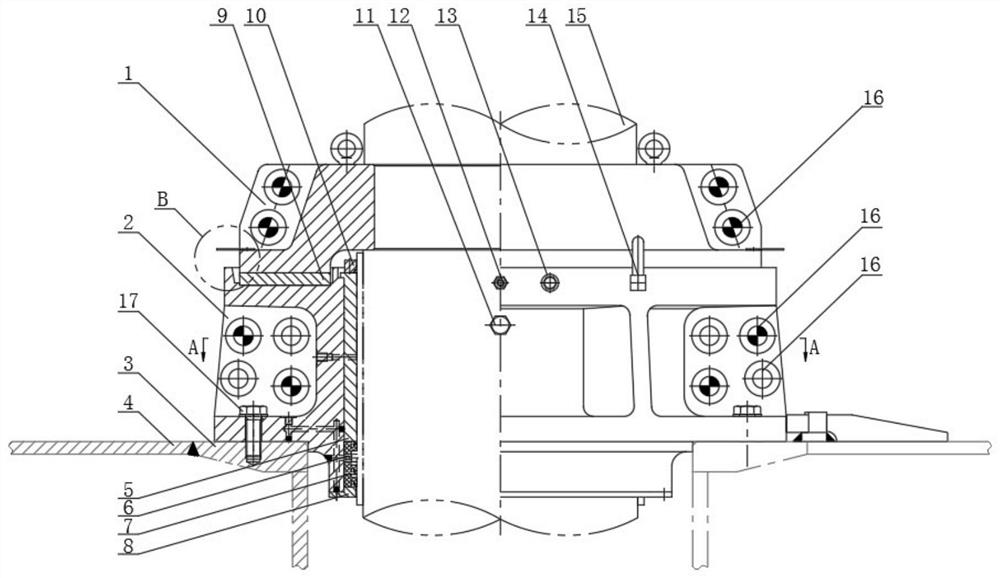

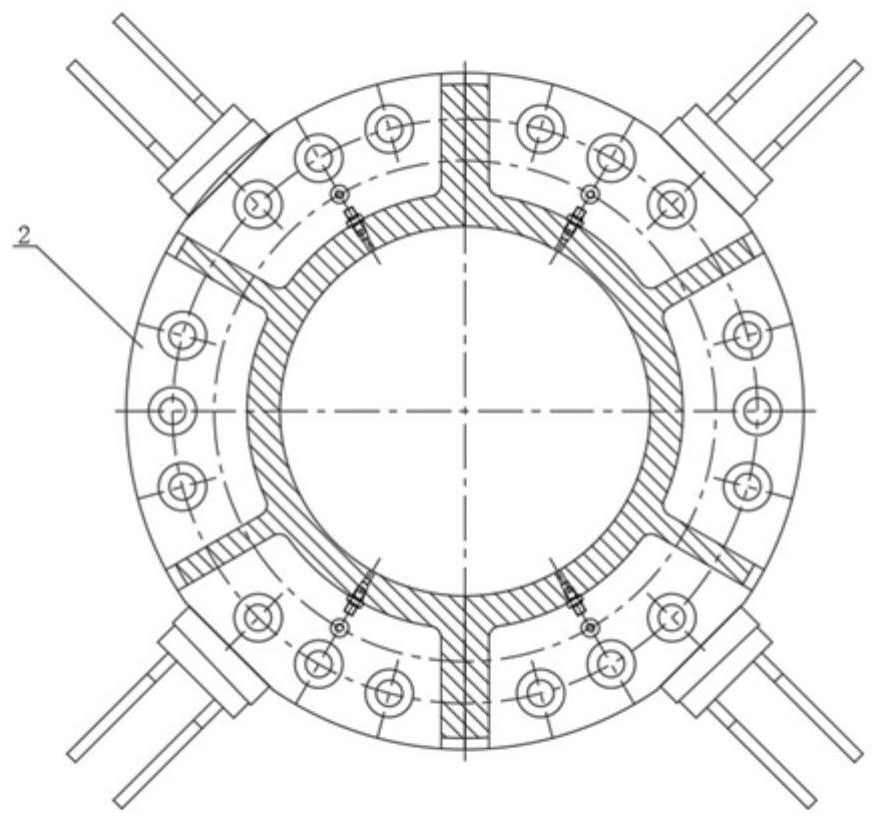

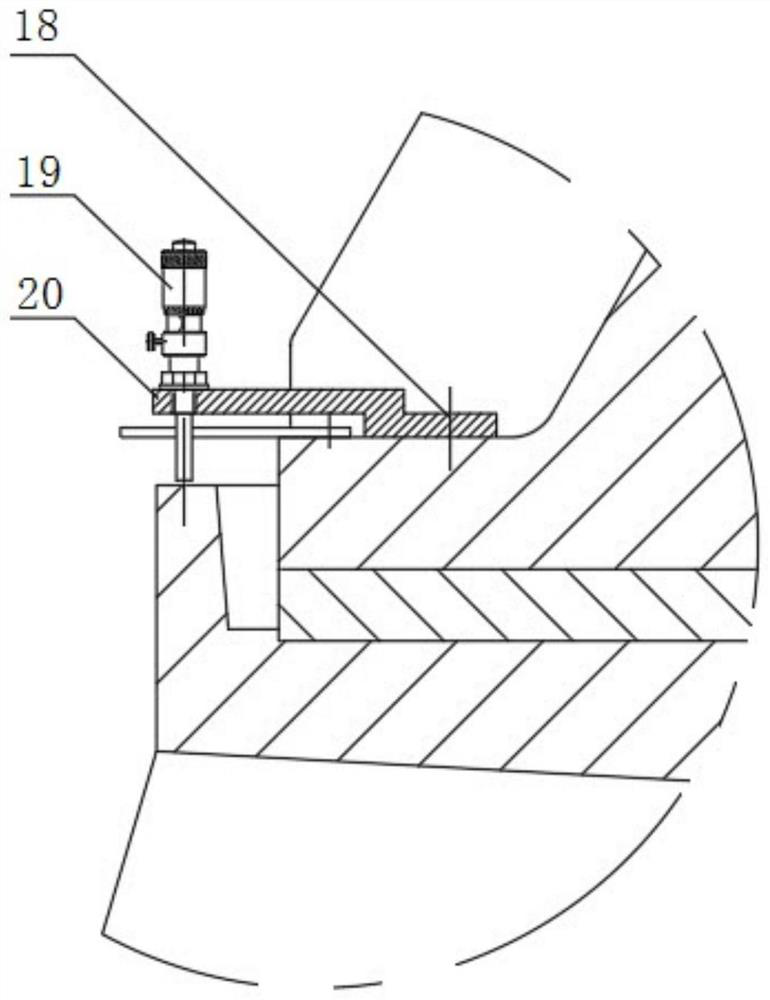

[0030]The upper helm provided by this embodiment, such asFigure 1 to 3As shown, the rudder sleeve 3 and the helm body 2 are used; the rudder sleeve 3 is used to securely connect with the steering machine deck 4; the bottom of the helm body 2 has a flange, the flange projects into the rudder sleeve 3, and the flange The outer wall is fitted to the inner wall of the rudder sleeve 3; the helm body 2 is fixed to the rudder sleeve 3.

[0031]The outer wall of the flange cooperates with the inner wall of the rudder sleeve 3 to assist the helm body 2, rotate the helm body 2 to the mounting position, and secure the helm body 2 in the helm body 2 in the rudder sleeve 3 through the hex head bolt 17, easy to operate. When replacing the seal, simply take the helm body 2 to the lower length, there is no need to hang the helm body 2, the desired space is small, and the hanging rudder body 2 is removed to complete the seal replacement, It is convenient to maintain and high efficiency. Further, the up...

Embodiment 2

[0044]The rudder system provided in this embodiment includes the upper rudering provided by Example 1. The outer wall of the flange cooperates with the inner wall of the rudder sleeve 3 to assist the helm body 2, rotate the helm body 2 to the mounting position, and secure the helm body 2 in the helm body 2 in the rudder sleeve 3 through the hex head bolt 17, easy to operate. When replacing the seal, simply take the helm body 2 to the lower length, there is no need to hang the helm body 2, the desired space is small, and the hanging rudder body 2 is removed to complete the seal replacement, It is convenient to maintain and high efficiency.

Embodiment 3

[0046]The ship provided in this embodiment includes a rudder system provided by the upper rudder or Example 2 provided in Example 1. The outer wall of the flange cooperates with the inner wall of the rudder sleeve 3 to assist the helm body 2, rotate the helm body 2 to the mounting position, and secure the helm body 2 in the helm body 2 in the rudder sleeve 3 through the hex head bolt 17, easy to operate. When replacing the seal, simply take the helm body 2 to the lower length, there is no need to hang the helm body 2, the desired space is small, and the hanging rudder body 2 is removed to complete the seal replacement, It is convenient to maintain and high efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com