Uniform grease adding equipment for feed production

A technology for adding equipment and oil, which is applied in the field of equipment for evenly adding oil for feed production. It can solve the problems of many operation steps and low work efficiency, and achieve the effect of maintaining a uniform output speed, reducing labor intensity, and reducing resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

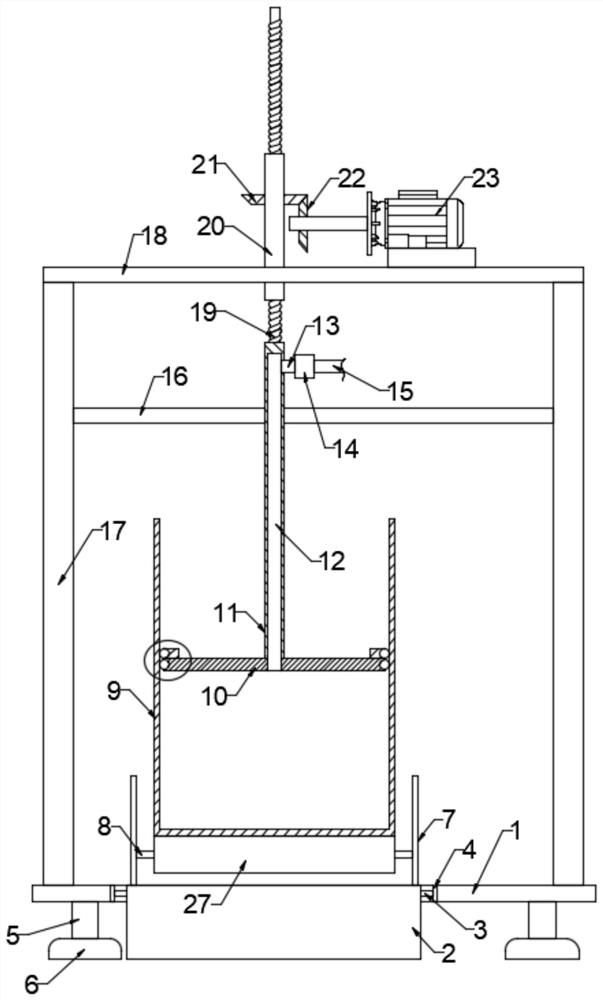

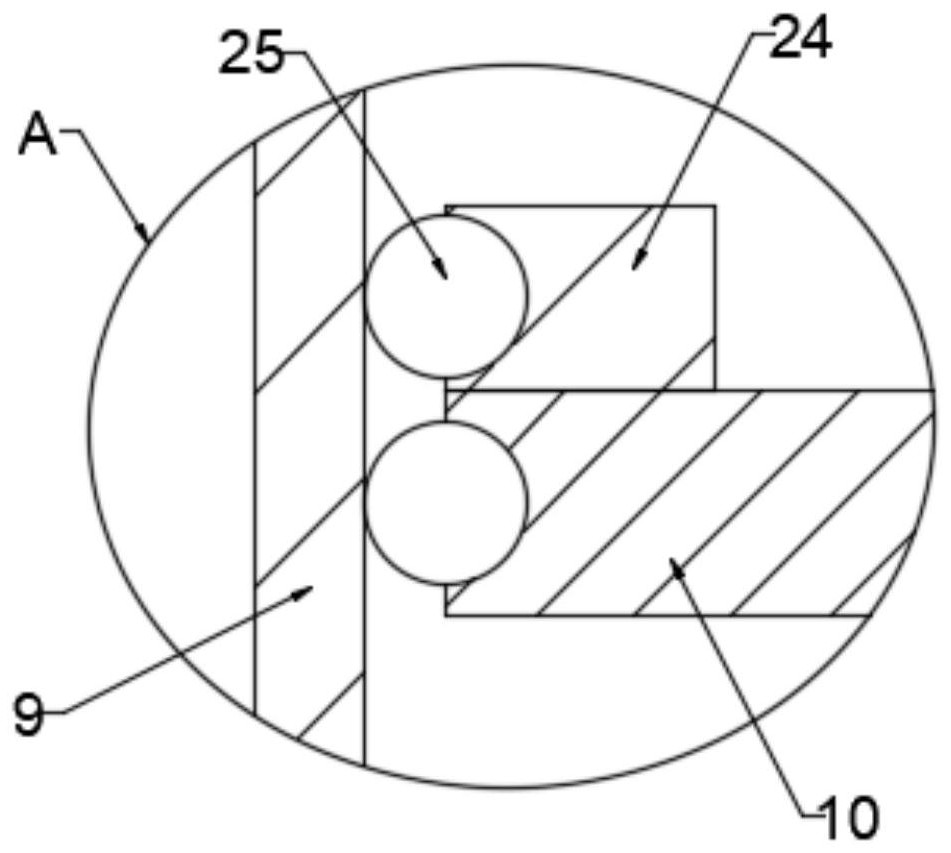

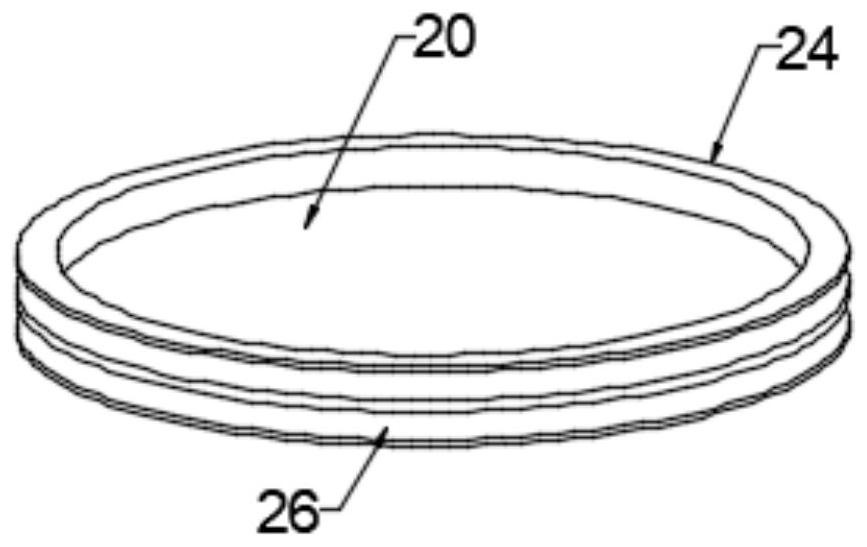

[0024] see Figure 1-5 , a kind of equipment for evenly adding grease for feed production, comprising a base 1, a grease bucket 9 filled with grease is arranged on the top of the base 1, the grease bucket 9 is positioned by a positioning component, and the grease bucket 9 is also connected to make it easy to replace Auxiliary handling assembly, the grease barrel 9 is nested with an extruding piston plate 10, the extruding piston plate 10 and the inner wall assembly of the grease barrel 9 are provided with a sealing assembly, and the axis of the extruding piston plate 10 is fixedly connected with a prismatic extruding rod 11. The prismatic extruding rod 11 is connected with an extruding mechanism that drives it up and down. The prismatic extruding rod 11 is provided with a grease channel 12 that communicates with the cavity of the grease barrel 9 below the extruding piston plate 10. The grease channel 12 The other end is communicated with a connecting oil pipe 13, and the conne...

Embodiment 2

[0030] This embodiment is expanded on the basis of Embodiment 1. The anti-rotation assembly includes a limiting plate 16, which is fixedly connected to the two support plates 17, and the limiting plate 16 is connected to the prismatic extrusion rod. 11 is slidingly connected, so that the prismatic extrusion rod 11 is limited, and the prismatic extrusion rod 11 can be prevented from rotating, so that the prismatic extrusion rod 11 drives the extrusion piston plate 10 and the lifting screw 19 follows the driving screw sleeve 20 relative Rotate, can't play the effect of lifting and extruding.

[0031] The working principle of the present invention is: firstly, by placing the grease bucket 9 on the roller 27, push the grease bucket 9 onto the base 1 along the roller 27, and then push the grease bucket 9 to the first roller at a certain angle 27, then through, each of the rollers 27 drives the grease barrel 9 to move, reducing the resistance of the push, reducing labor intensity, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com