Combined type hydraulic control valve

A hydraulic control valve and combined technology, applied in the directions of servo motor components, fluid pressure actuating devices, mechanical equipment, etc., can solve the problems of commutation change, easy vibration or accidental touch, etc., and achieve safe and convenient use and scientific structure. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]Next, the technical solutions in the embodiments of the present invention will be apparent from the embodiment of the present invention, and it is clearly described, and it is understood that the described embodiments are merely embodiments of the present invention, not all of the embodiments. Based on the embodiments of the present invention, there are all other embodiments obtained without making creative labor without making creative labor premises.

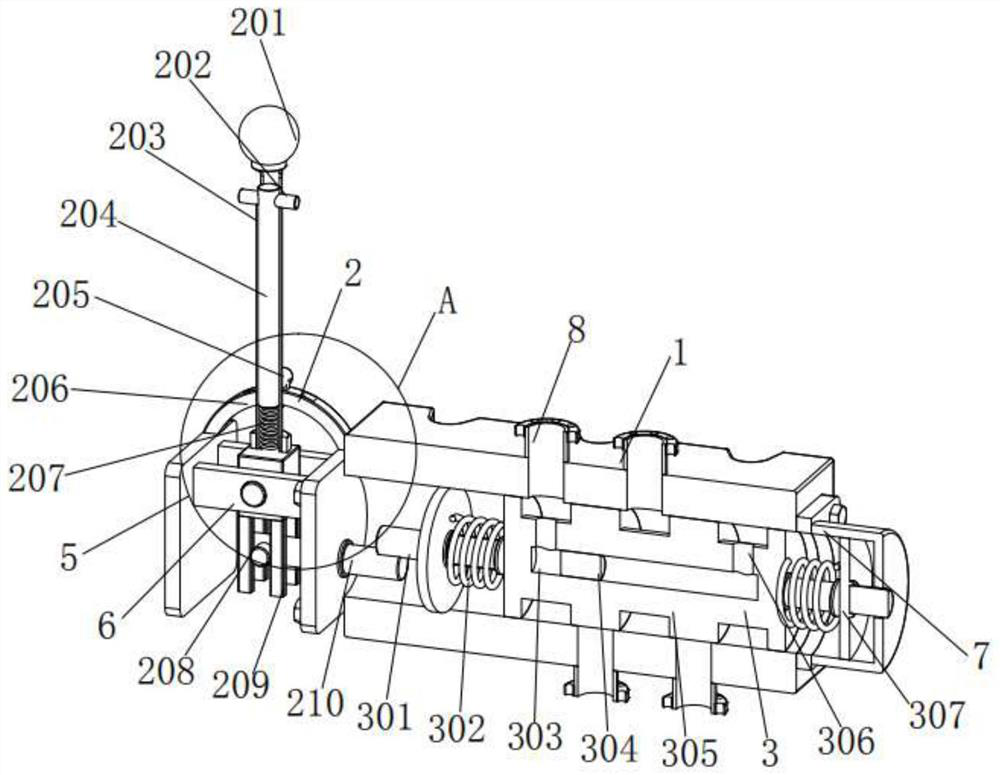

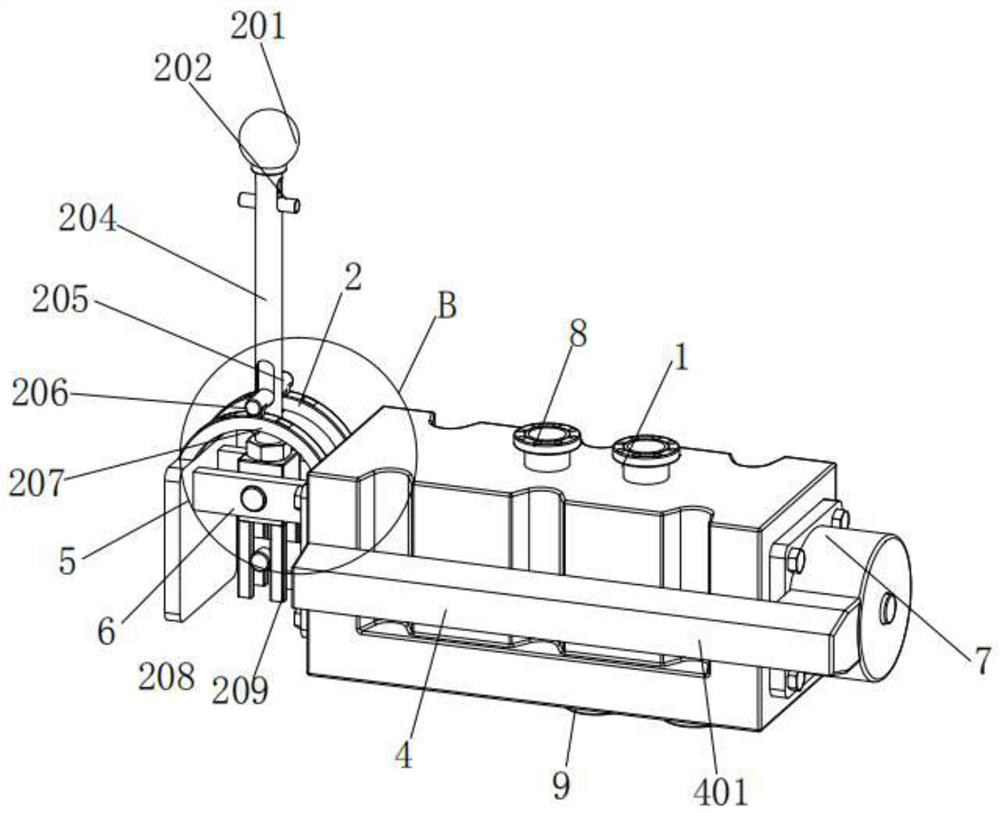

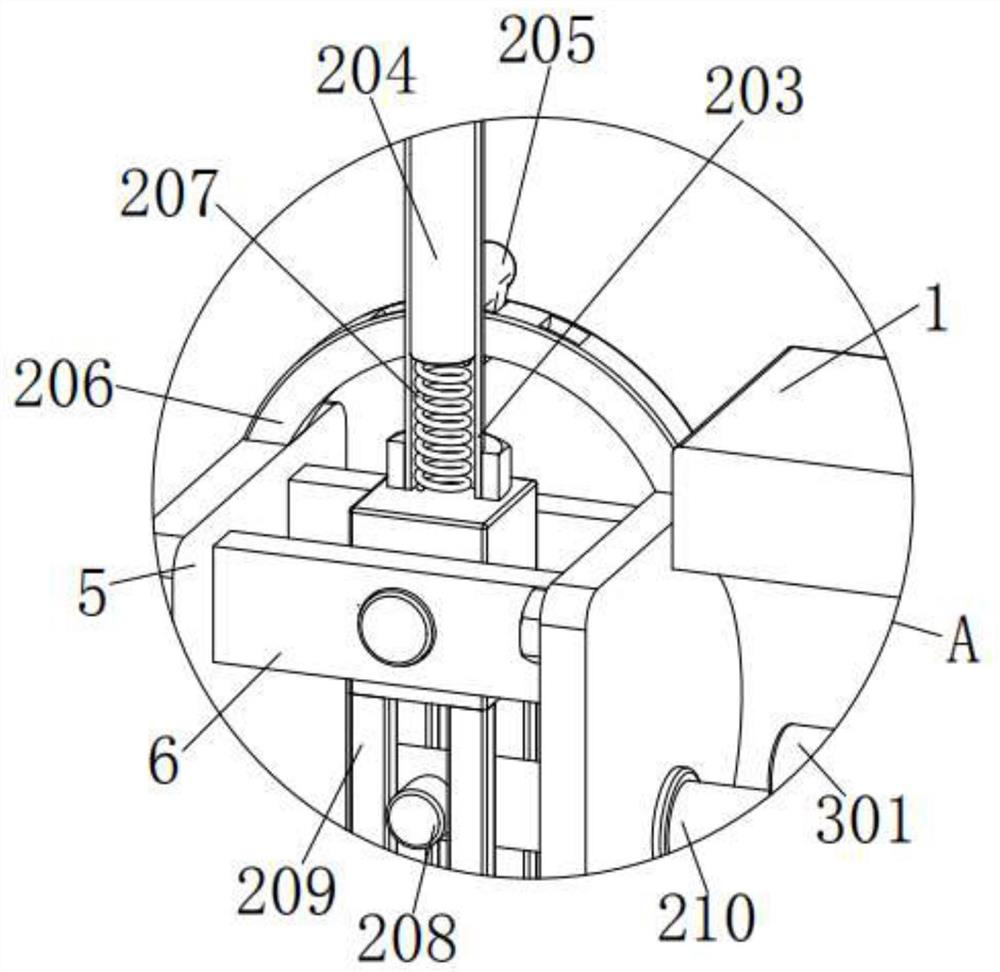

[0032]SeeFigure 1-7The present invention provides a technical solution: a combined hydraulic control valve comprising a vertical panel 5 and a cross plate 6, and both sides of the plurality of vertical plates 5 are fixed, and the horizontal plate 6 is fixed. The inner side is provided with a drive assembly 2, and the drive assembly 2 includes a spherical 201, a handle 202, a sleeve 203, a vertical rod 204, a block 205, an arc 206, a first spring 207, a rod 208, a vertical rod 209, and a first cross. The rod 210, the lower end out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com