Bearing steel ball size detection device

A technology for size detection and bearing steel balls, which is applied in the direction of measuring devices, mechanical measuring devices, and mechanical devices, etc., can solve the problems of steel ball size error, large number of steel balls, and large error range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

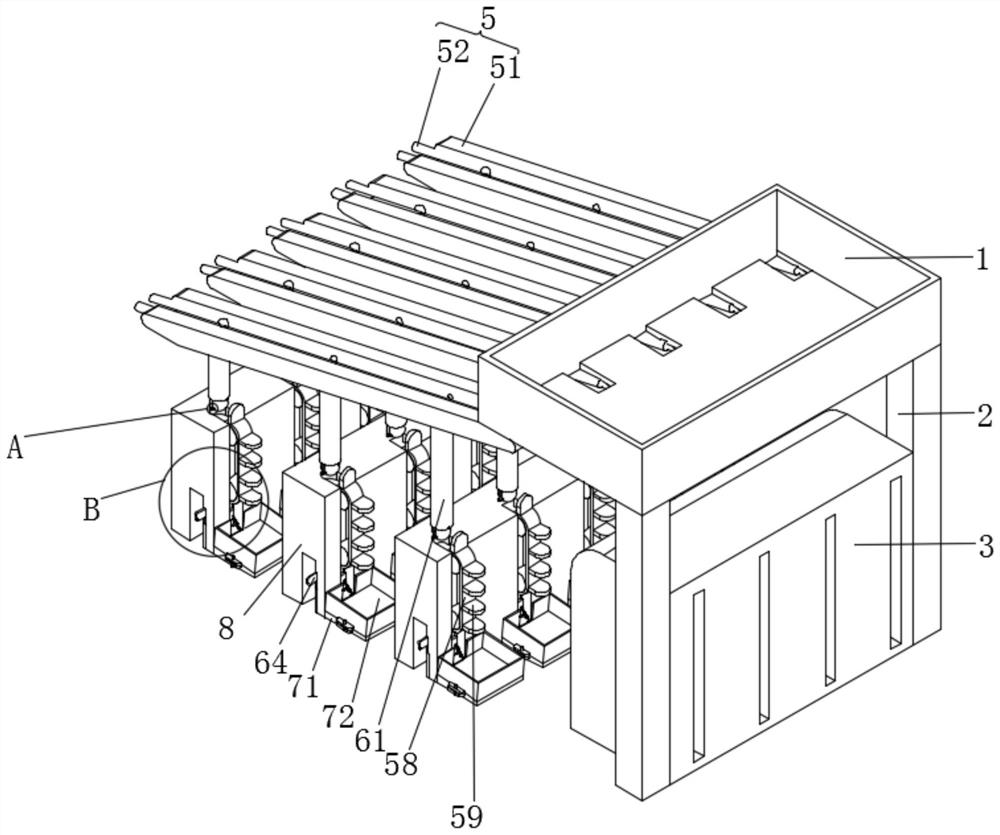

[0030] Example 1, such as Figure 1-8 As shown, the present invention provides a bearing steel ball size detection device, including a placement box 1 and a screening structure 5, the bottom end of the placement box 1 is fixedly connected with two connecting columns 2, and the ends of the two connecting columns 2 are close to each other A connecting frame 3 is fixedly connected, the surface of the connecting frame 3 is fixedly connected with the wall by means of bolts, and a screening structure 5 is provided at the bottom of the placing box 1 .

[0031]Let's talk about the specific settings and functions of its screening structure 5, detection structure 6 and collection structure 7 in detail below.

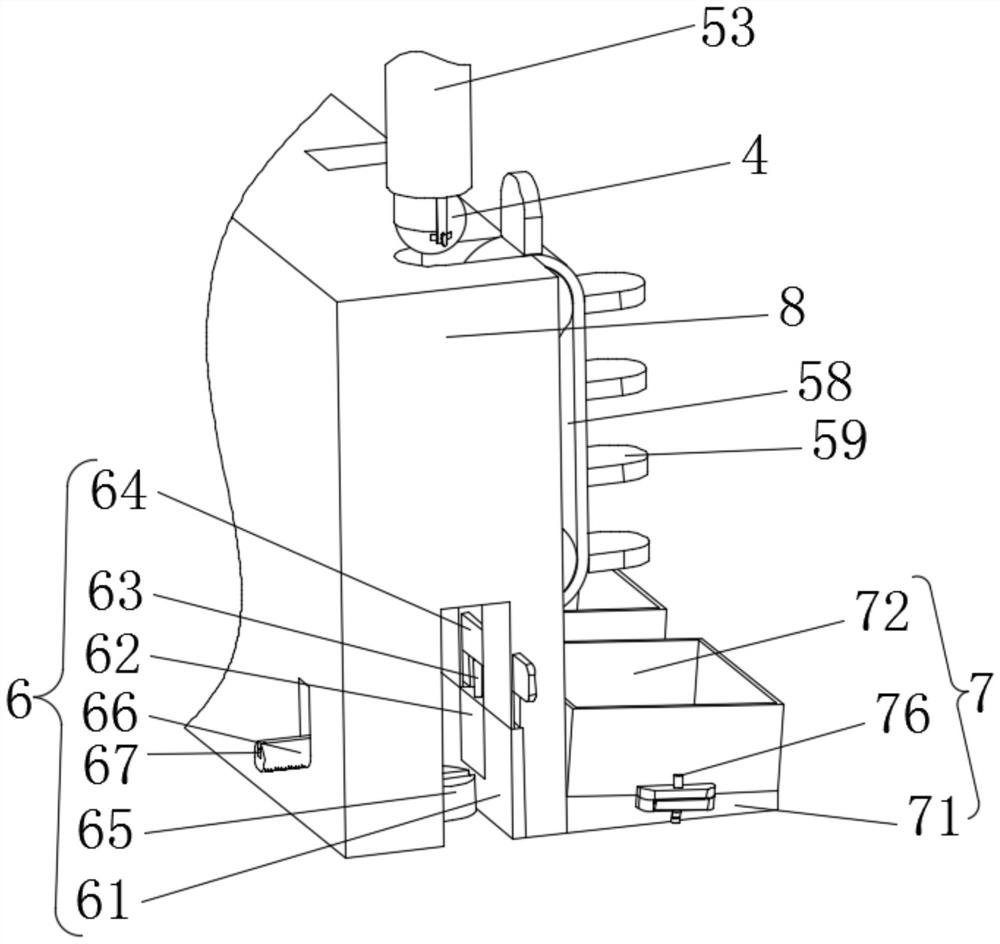

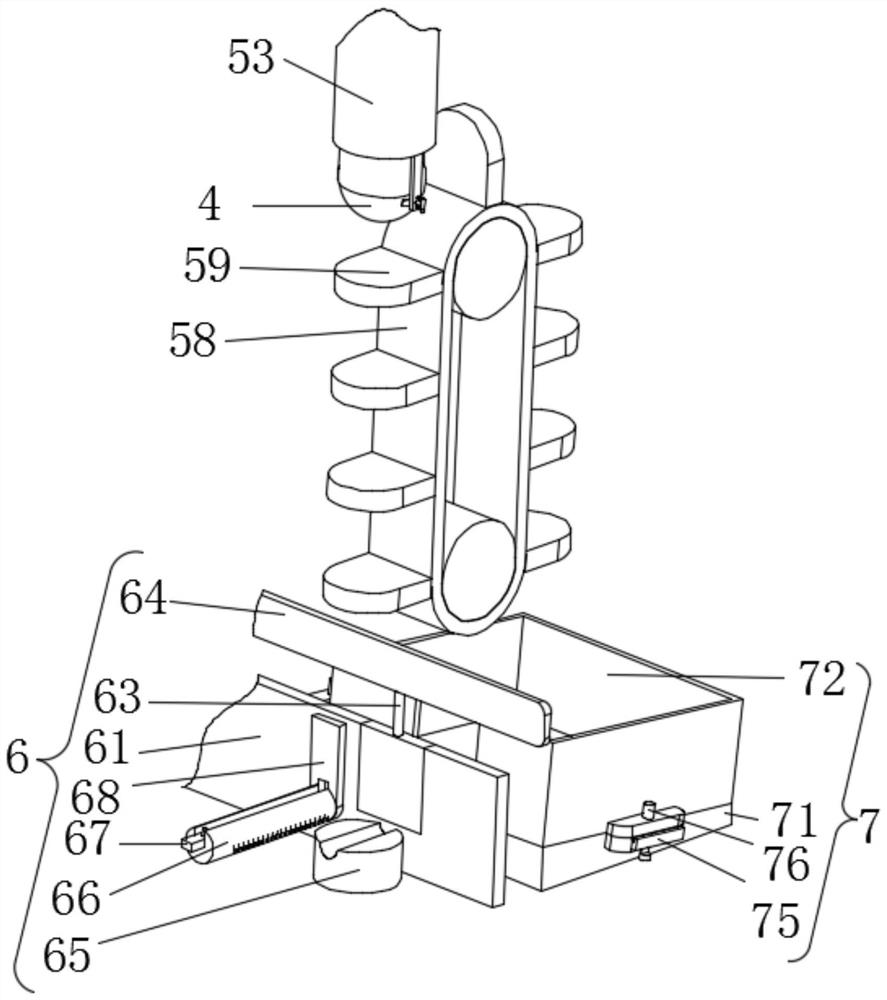

[0032] Such as figure 1 and figure 2 As shown, the screening structure 5 includes a long column 51, the surface of the long column 51 is fixedly connected with the placement box 1, the upper surface of the long column 51 is provided with a chute, and the inner wall of the chute...

Embodiment 2

[0036] Embodiment 2, on the basis of embodiment 1, as figure 1 and Figure 6 As shown, the end of the rectangular column 8 away from the long rod 66 is provided with a collection structure 7, the collection structure 7 includes a fixed seat 71, the surface of the fixed seat 71 is fixedly connected with the rectangular column 8, and the side wall of the fixed seat 71 is fixedly connected with a fixed block 74 , the upper surface of the fixed seat 71 is placed with a collection box 72, the side wall of the collection box 72 is fixedly connected with a connection block 73, the inside of the connection block 73 is inserted with a plunger 76, and the surface of the plunger 76 is fixedly connected with the connection block 73, One end of the fixed block 74 away from the fixed base 71 is inserted with a plug 75, the surface of the plug 75 is slidably connected with the fixed block 74, and the surface of the fixed block 74 is provided with a slot, and the size of the slot is the same ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com