High-capacity, high-magnification and high-tap-density sodium ion battery positive electrode material and preparation method thereof

A sodium-ion battery and cathode material technology, applied in battery electrodes, positive electrodes, secondary batteries, etc., can solve the problems of fast capacity decay, low tap density, high raw material cost, and achieve reliable performance improvement, obvious performance improvement, The effect of improving cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

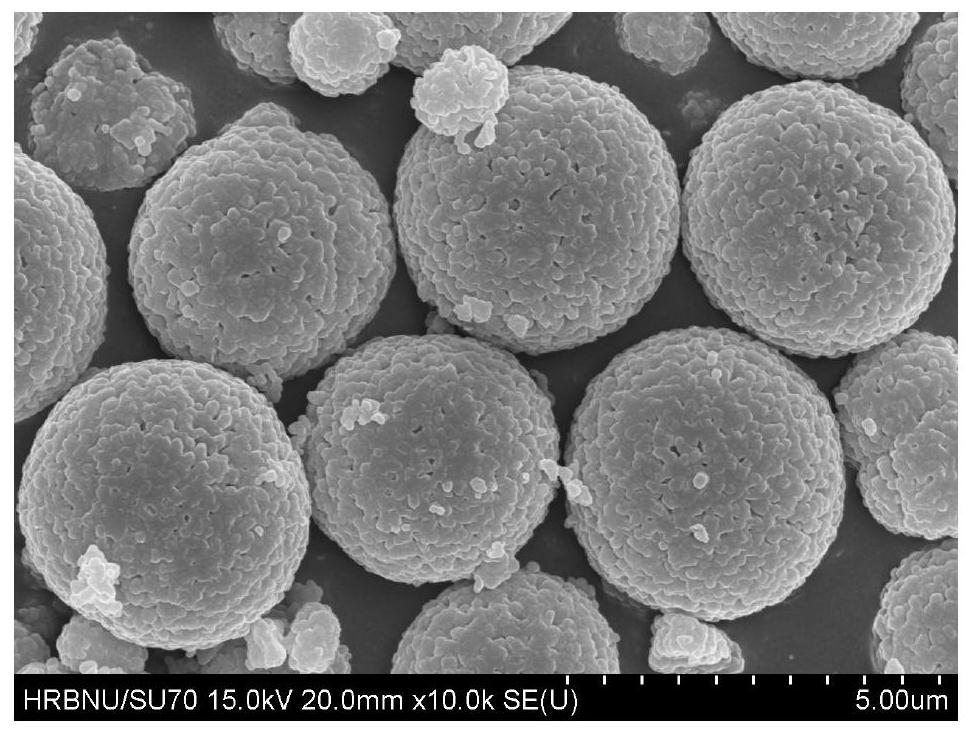

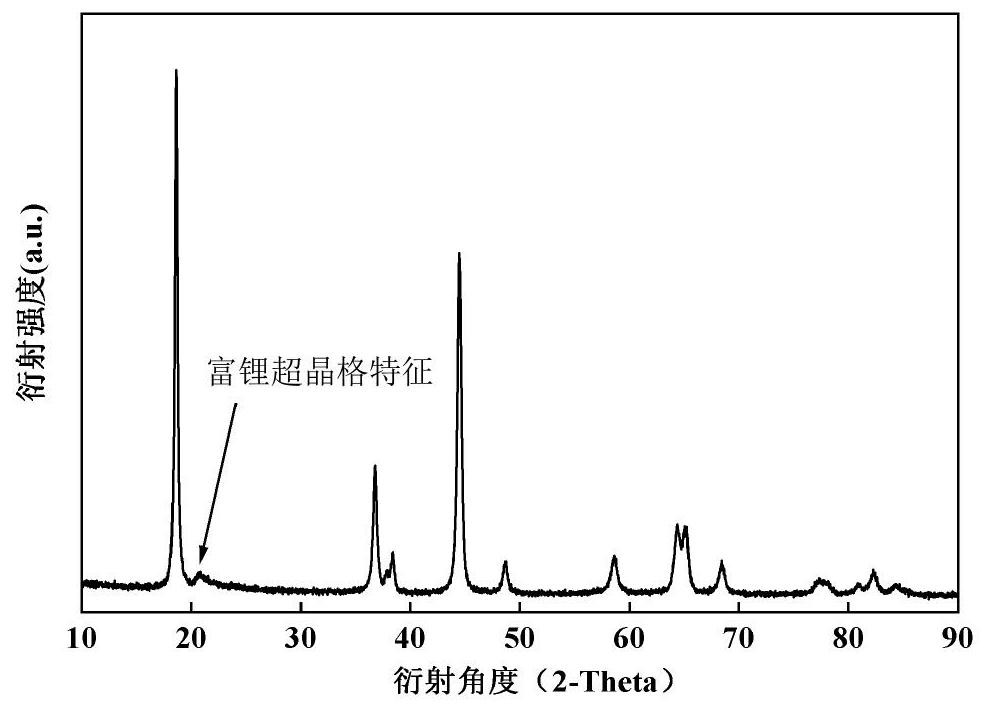

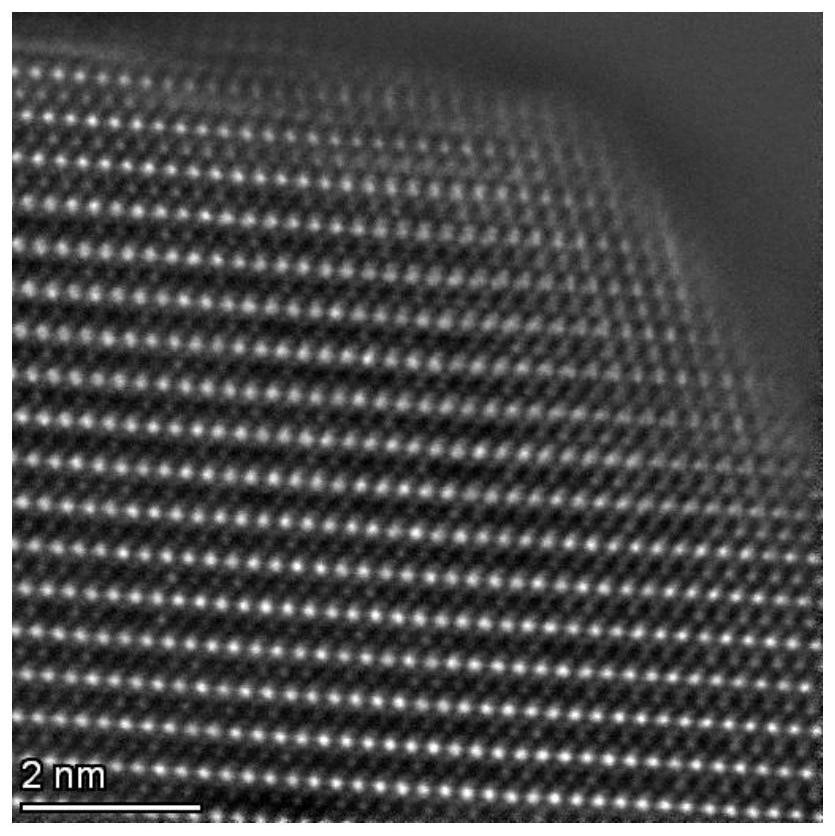

[0037] Specific embodiment one: what this embodiment records is a kind of positive electrode material of high capacity, high rate and high tap density sodium ion battery, and the chemical formula of described positive electrode material is Li[Na a+b (Mn x Ni y co z ) 1-a-b ]O 2 , where, 0

specific Embodiment approach 2

[0038] Specific embodiment two: a method for preparing the high-capacity, high-rate and high-tap-density sodium-ion battery positive electrode material described in specific embodiment one, using the method of co-precipitation, high-temperature sintering and ion exchange reaction, the method steps as follows:

[0039] Step 1: Prepare manganese-nickel-cobalt carbonate spherical precursor by co-precipitation method, the specific steps are as follows:

[0040] (1) According to the chemical formula Li[Li a (Mn x Ni y co z ) 1-a ]O 2 Weigh soluble manganese salts, nickel salts, cobalt salts and crystal nucleation control agents in corresponding molar ratios, dissolve the above raw materials in deionized water to prepare a total concentration of manganese, nickel and cobalt of 0.5 to 5 mol / L, and crystal nucleation control agent concentration Solution A of 0.05~0.5mol / L;

[0041] (2) Deionized water is used to configure the carbonate precipitating agent and complexing agent i...

Embodiment 1

[0055] Weigh manganese sulfate, nickel sulfate, and cobalt sulfate according to the molar ratio Mn:Ni:Co=0.54:0.13:0.13, and weigh a certain amount of crystal nucleation control agent (polyvinylpyrrolidone), and dissolve the above raw materials in deionized water It is configured into solution A that the total concentration of manganese, nickel and cobalt is 0.5mol / L, and the concentration of the crystal nucleation control agent is 0.05mol / L, and 0.5mol / L sodium carbonate precipitant and 0.2mol / L complexing agent are mixed by co-precipitation. The solution (ammonium bicarbonate) is added in the above-mentioned solution A, the molar ratio of control mixed metal salt, crystal nucleation control agent, carbonate precipitation agent and complexing agent is 1:0.1:1:0.2, and stirring speed is 1200 revs / min and a temperature of 25°C for 2 hours. After the reaction, filter with suction, wash repeatedly to remove impurities, and dry to obtain a spherical precursor of manganese-nickel-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap