10kv column type porcelain bottle wire self-locking device

A self-locking device, 1.10kv technology, applied in the direction of adjusting/maintaining mechanical tension, etc., to avoid excessively long transmission lines, improve insulation, and reduce shaking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

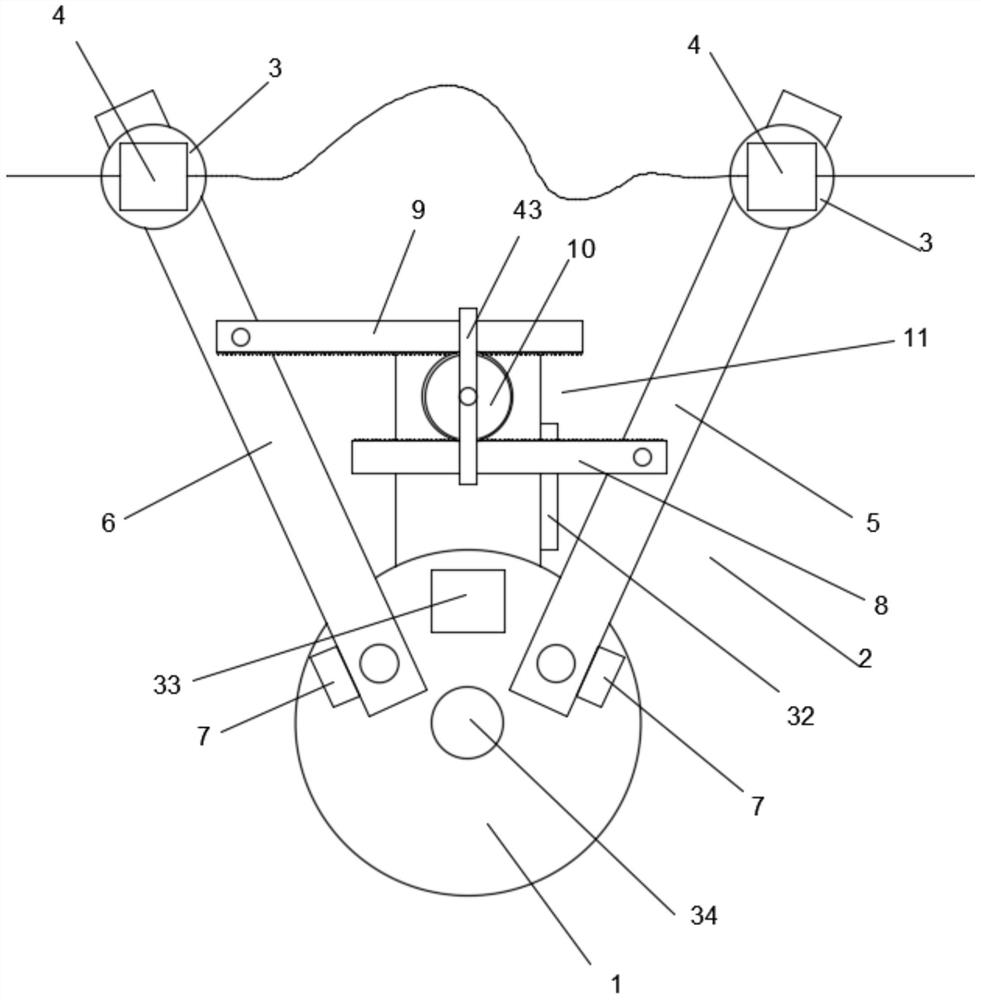

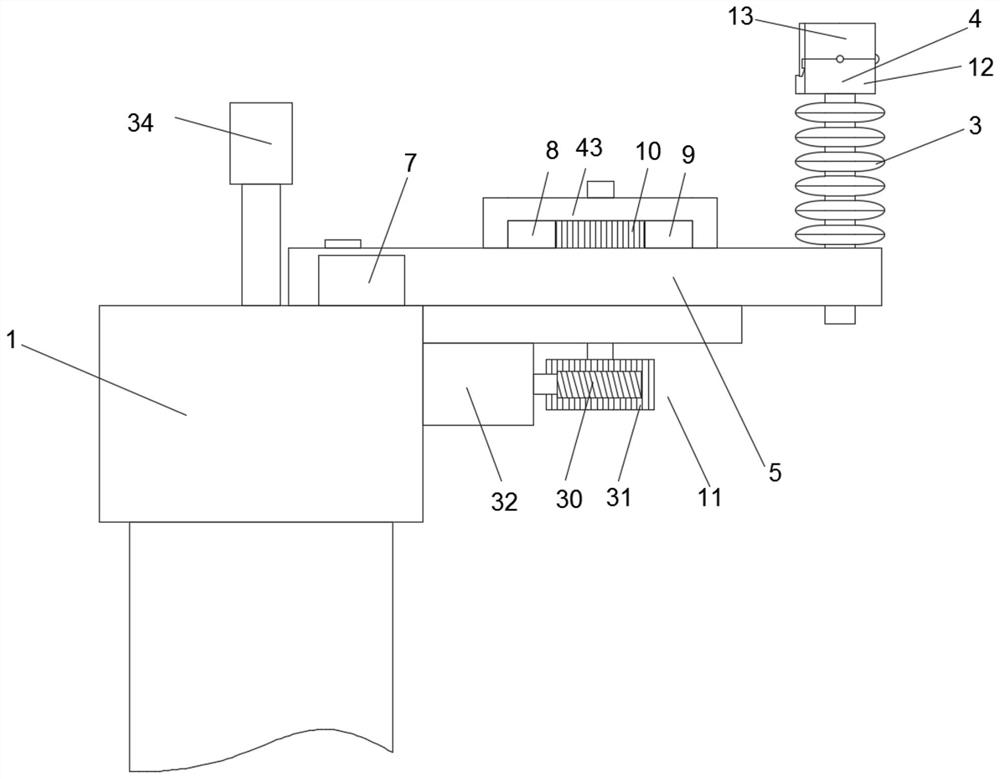

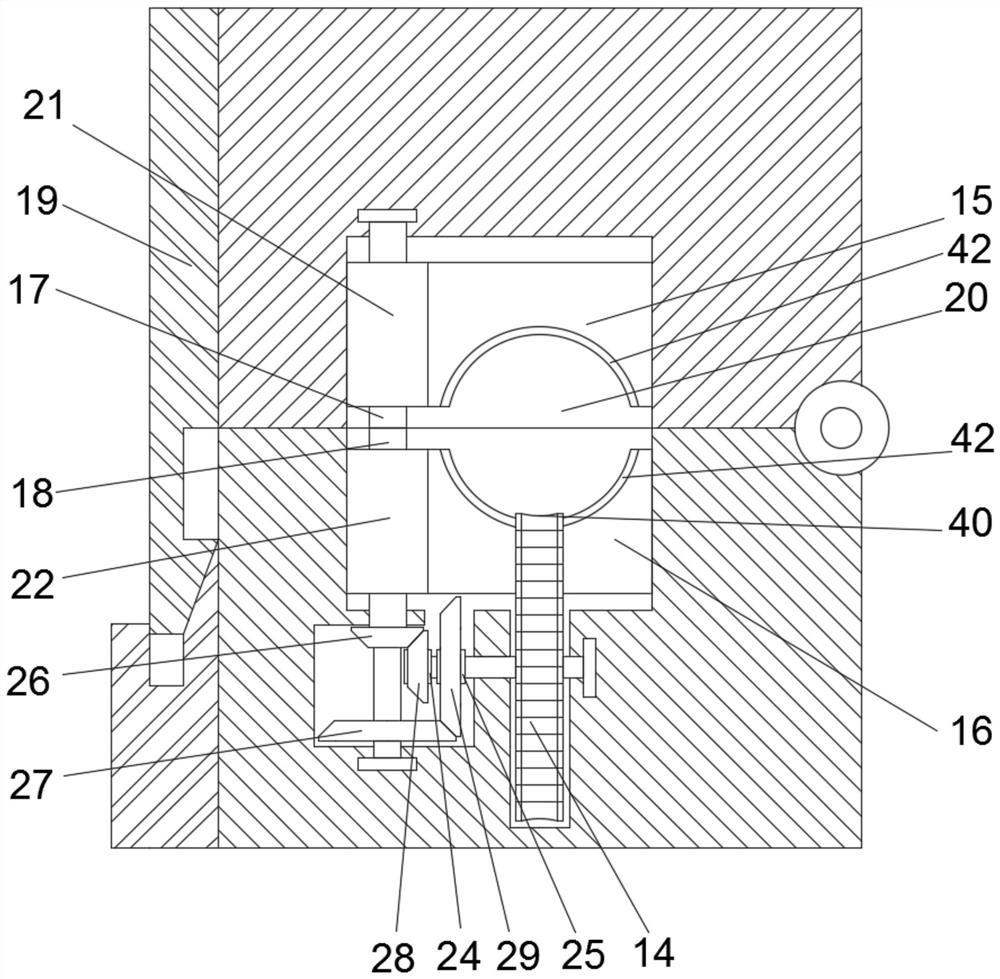

[0026] see Figures 1 to 5 , 10kV column-type porcelain bottle wire self-locking device, including base 1, adjusting cross arm 2, insulator 3 and holder 4; the base 1 is used to connect with the transmission pole, and the base 1 is connected with the adjustment Cross-arm 2; Described adjustment cross-arm 2 includes first cross-arm 5 and second cross-arm 6, and described first cross-arm 5 and second cross-arm 6 are respectively connected to the base 1 in rotation, and the base 1. There is a limit block 7 that restricts the rotation angle of the first cross arm 5 and the second cross arm 6, the first cross arm 5 is rotatably connected with the first rack 8, and the second cross rail is rotatably connected with the first rack 8. Two racks 9, the base 1 is provided with a first gear 10 that meshes with the first rack 8 and the second rack 9 at the same time, the base 1 is provided with a drive to drive the first gear 10 to rotate Mechanism 11; the first cross arm 5 and the second...

Embodiment 2

[0035] see Figures 6 to 7 The difference between this embodiment and Embodiment 1 is that the driving mechanism 11 includes a first windward plate 35, a second windward plate 36 and a windshield frame 37, and an opening of one end of the windshield frame 37 is provided with a first windward plate 35, the other end opening is provided with a second windward plate, the first windward plate and the second windward plate 36 are respectively slidably connected to the base 1, and the first windward plate 35 and the second windward plate are parallel to the transmission line , the first windward plate 35 is provided with a third rack 38, the second windward plate 36 is provided with a fourth rack 39, and the third rack 38 and the fourth rack 39 are respectively engaged with the A gear 10 on both sides. The first windward plate and the second windward plate 36 are respectively slidably connected to the base 1 . Optionally, the first windward plate and the second windward plate 36 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com