Surface acoustic wave resonator and method for manufacturing surface acoustic wave resonator

A technology of surface acoustic wave and manufacturing method, which is applied in the manufacturing field of surface acoustic wave resonator and temperature-compensated surface acoustic wave resonator, can solve the problem of easily broken fingers and the like, and achieves high Q value, low frequency temperature coefficient, Effect of high electromechanical coupling coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0047] [Surface Acoustic Wave Resonators]

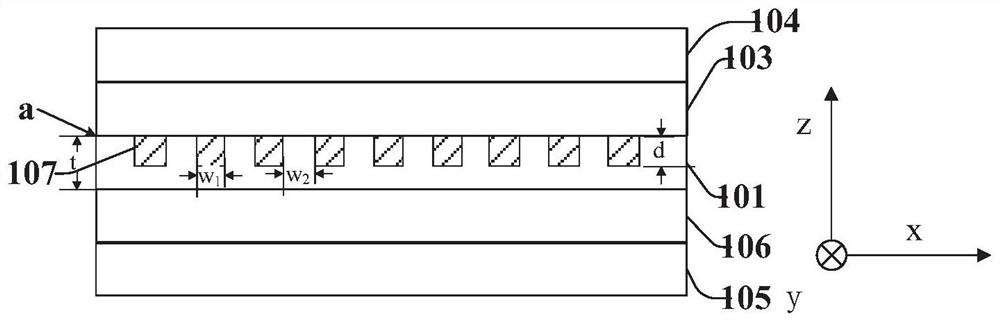

[0048] figure 1It is a side view of the structure of the surface acoustic wave resonator according to Embodiment 1 of the present invention. The propagation direction of the surface acoustic wave is the width direction of the electrode fingers (ie figure 1 The left and right direction) is the x-axis, and the thickness direction of the piezoelectric material layer 101 (ie figure 1 The up and down direction in the center) is the z-axis.

[0049] The following combination figure 1 , the structure of the surface acoustic wave resonator of the present invention shown in the figure will be described.

[0050] The surface acoustic wave resonator of the present invention adopts a piezoelectric film structure, and a substrate 105, a third dielectric layer 106, a piezoelectric material layer 101, a first dielectric layer 103, and a second dielectric layer 104 are stacked sequentially from bottom to top, An interdigitated electrode compose...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com