Combined seed and fertilizer drill with automatic calibration function

An automatic calibration and seeder technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve the problems of complicated operation, long time, large error, etc., and achieve the effect of simple calibration operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

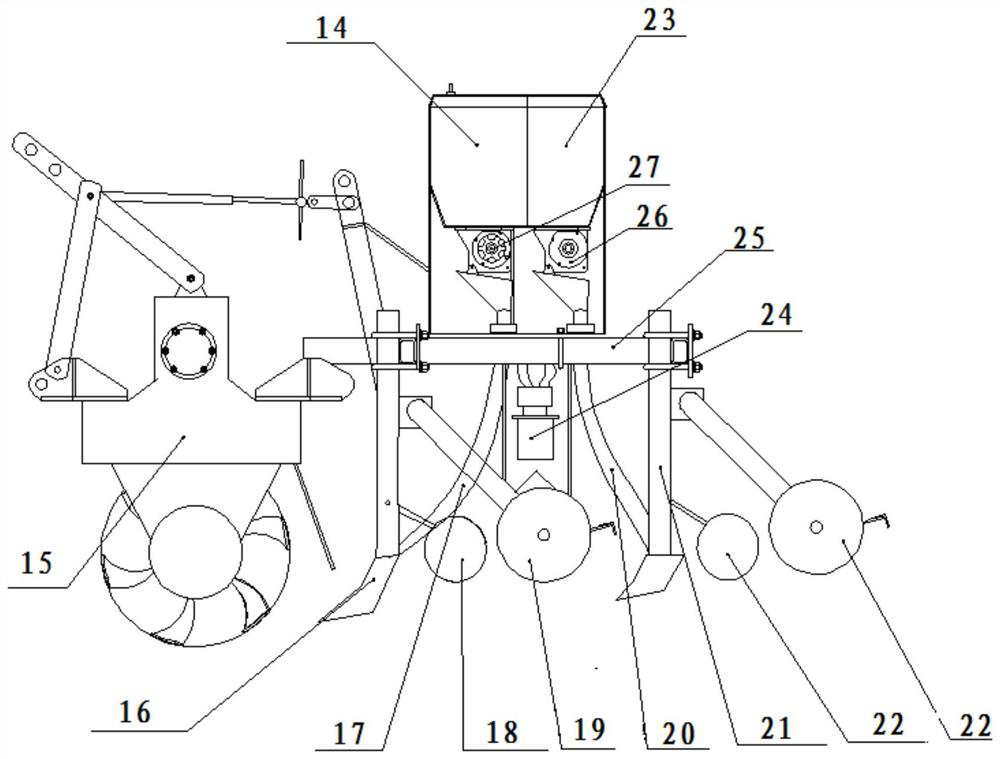

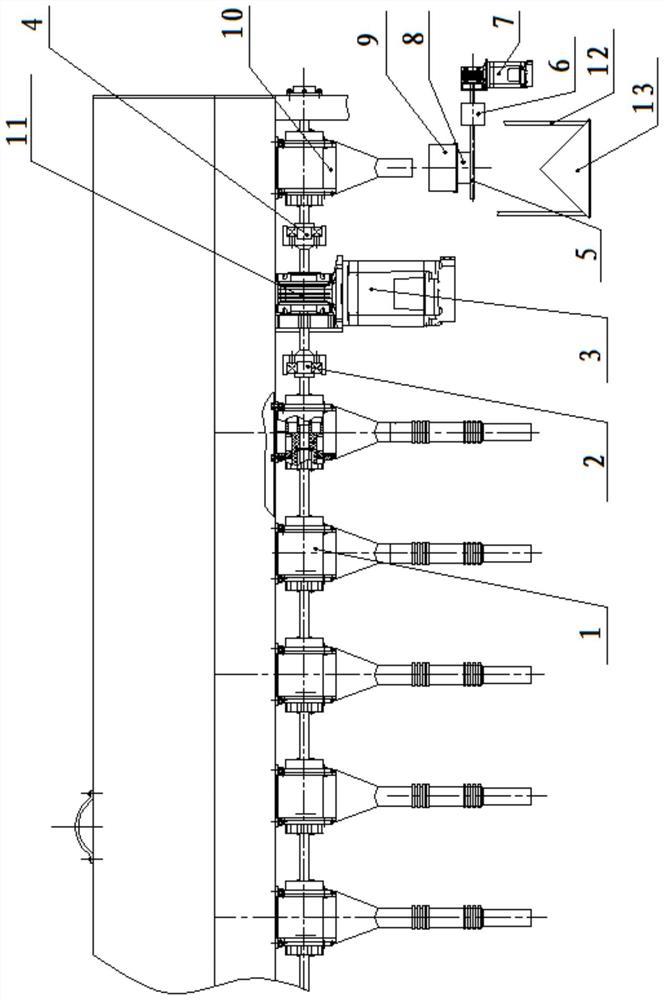

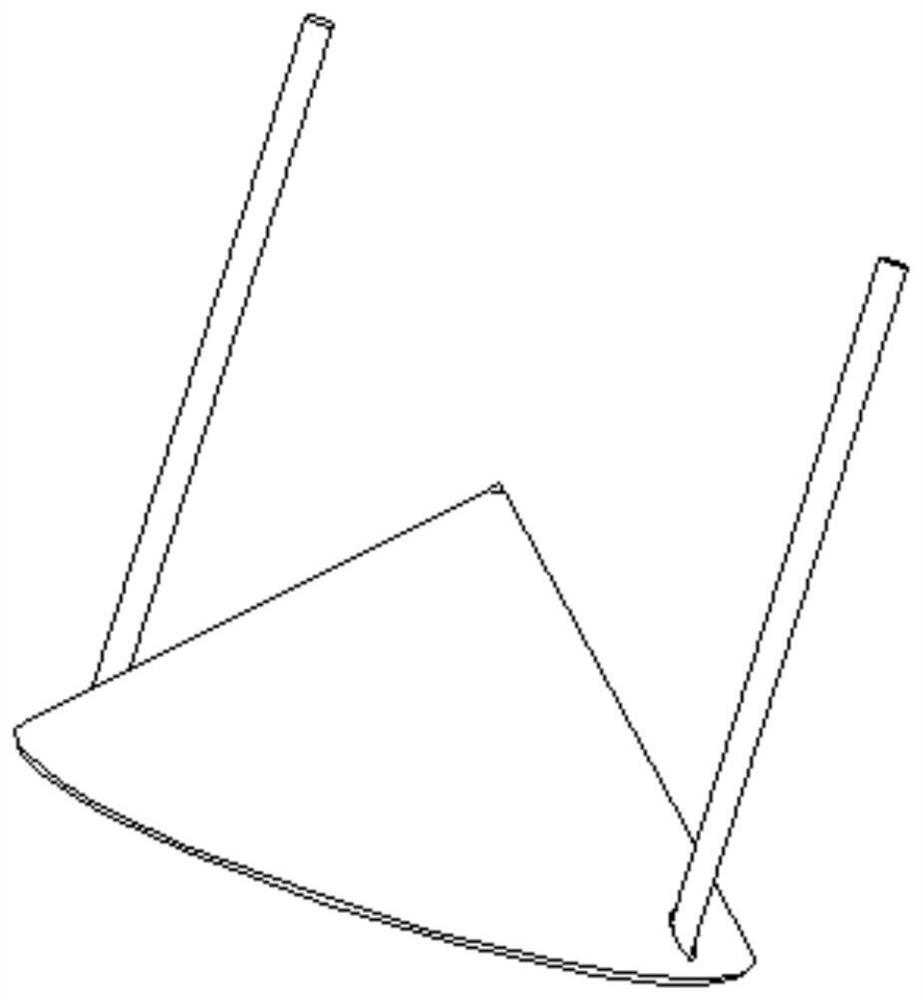

[0031] see Figure 1-5 , a fertilizing and seeding machine with automatic calibration function, the power part that can be rotated positively and negatively has double-sided power output ends; one side is connected with the operation row seed row and fertilizer part 1 through the first transmission one-way bearing 2, and the other side The second transmission one-way bearing 4 is connected with the seed row and fertilizer component 10 for calibration; the locking direction of the first transmission one-way bearing 2 and the second transmission one-way bearing 4 are opposite, and the free rotation direction is opposite; The lower part of the fertilizer discharge part 10 is provided with an inoculation and fertilizer receiving box 9, and the lower part of the inoculation and fertilizer receiving box 9 is provided with a load-bearing sensor 8; the supporting control system is connected with the load-bearing sensor 8 and the power component; the comparator controls the target seedi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com